15v led flasher version b

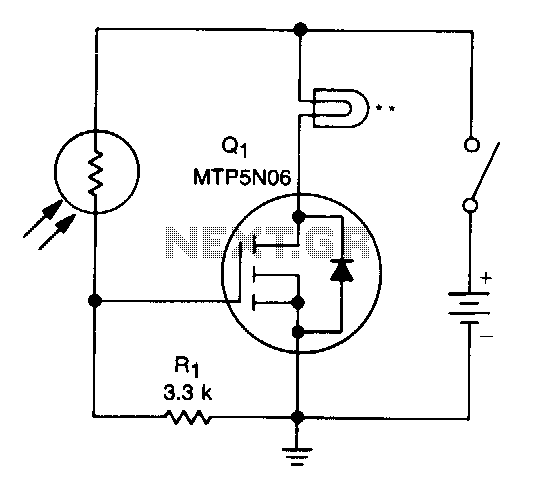

This circuit is designed to extract additional energy from an alkaline battery cell by incorporating two transistors into a configuration similar to a previously mentioned design, thereby enhancing efficiency. A standard 1.5-volt alkaline N cell is capable of powering an LED for an entire year. The circuit employs a "charge pump" technique to supply the necessary voltage for the LED.

The circuit utilizes a charge pump configuration to effectively boost the voltage supplied to the LED, allowing for prolonged operation from a single alkaline battery. The inclusion of two transistors plays a critical role in improving the circuit's efficiency by enabling the switching action required for the charge pump to function effectively.

In this design, the first transistor acts as a switch that controls the charging of a capacitor from the battery. When this transistor is activated, current flows from the battery into the capacitor, storing energy. The second transistor is used to discharge this stored energy into the LED, providing it with the higher voltage needed for illumination.

The charge pump operates in a cycle, where the capacitor is charged and discharged repeatedly, creating a pulsating current that can be smoothed out to provide a steady voltage to the LED. This method not only extends the lifespan of the battery by maximizing its energy output but also ensures that the LED remains lit for an extended period, potentially up to a year under optimal conditions.

To implement this circuit, careful selection of the transistors and capacitors is crucial, as their characteristics will determine the overall performance and efficiency of the charge pump. Additionally, the circuit may include resistors to limit current and protect the LED from excess voltage, ensuring reliable operation throughout the battery's life. Proper PCB layout and component placement can further enhance the performance of the circuit, minimizing losses and maximizing energy extraction from the alkaline battery.Circuit To squeeze even more energy from a alkaline battery cell, this circuit adds two transistors to a circuit similar to the above design to boost the efficiency. A small 1. 5 volt alkaline N cell should flash the LED for a full year. It too uses a "charge pump" technique to provide a LED the needed voltage. 🔗 External reference

The circuit utilizes a charge pump configuration to effectively boost the voltage supplied to the LED, allowing for prolonged operation from a single alkaline battery. The inclusion of two transistors plays a critical role in improving the circuit's efficiency by enabling the switching action required for the charge pump to function effectively.

In this design, the first transistor acts as a switch that controls the charging of a capacitor from the battery. When this transistor is activated, current flows from the battery into the capacitor, storing energy. The second transistor is used to discharge this stored energy into the LED, providing it with the higher voltage needed for illumination.

The charge pump operates in a cycle, where the capacitor is charged and discharged repeatedly, creating a pulsating current that can be smoothed out to provide a steady voltage to the LED. This method not only extends the lifespan of the battery by maximizing its energy output but also ensures that the LED remains lit for an extended period, potentially up to a year under optimal conditions.

To implement this circuit, careful selection of the transistors and capacitors is crucial, as their characteristics will determine the overall performance and efficiency of the charge pump. Additionally, the circuit may include resistors to limit current and protect the LED from excess voltage, ensuring reliable operation throughout the battery's life. Proper PCB layout and component placement can further enhance the performance of the circuit, minimizing losses and maximizing energy extraction from the alkaline battery.Circuit To squeeze even more energy from a alkaline battery cell, this circuit adds two transistors to a circuit similar to the above design to boost the efficiency. A small 1. 5 volt alkaline N cell should flash the LED for a full year. It too uses a "charge pump" technique to provide a LED the needed voltage. 🔗 External reference