4W Fluorescent lamp driver

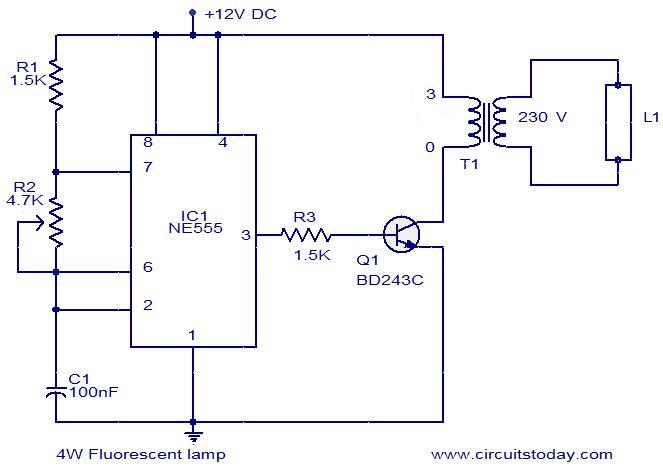

This is a simple 4W fluorescent lamp driver circuit that can be operated from a 12V supply. The first part of the circuit includes a NE555 timer IC configured as an astable multivibrator. The output pulses from the IC are amplified by the transistor Q1. The transformer steps up the collector voltage to around 1kV to drive the fluorescent lamp. Before using the circuit, set the resistor R2 to its maximum resistance and turn on the supply. Adjust R2 so that the collector current is 300mA (using a multimeter), which is the optimal setting for the lamp. Operating the lamp at this setting will enhance its lifespan. Initially, the tube is started with cold cathodes. The tube's life may be reduced as the cathode coating gradually wears away. This issue is not exclusive to this circuit; it is also observed in inexpensive battery-operated torches that have tubes with blackened ends. Additionally, due to the presence of a DC component in the tube supply from the single-ended drive to the transformer, one end of the tube will degrade faster than the other. The inefficiency of using a mains transformer—operating outside its intended frequency range and with interleaved core laminations saturating due to the DC component—results in the tube not receiving the full 4W of power. Furthermore, 300mA at 12V equates to only 3.6W, leading to reduced brightness compared to a lamp powered from the mains. A push-pull converter, operating at high frequency, utilizing a ferrite transformer, and featuring filament windings to preheat the cathodes, presents the optimal solution for operating fluorescent tubes from low-voltage DC.

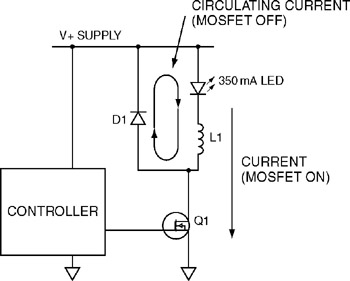

This circuit employs a NE555 timer IC configured as an astable multivibrator to generate a square wave output, which is essential for driving the fluorescent lamp. The frequency of oscillation can be adjusted by varying the resistors and capacitors connected to the NE555, allowing for fine-tuning of the output pulses. The transistor Q1 serves as an amplifier to boost the output from the NE555, supplying sufficient current to the transformer.

The transformer is a critical component, designed to step up the voltage from the collector of Q1 to approximately 1kV, which is necessary for igniting and sustaining the discharge in the fluorescent lamp. The design must consider the transformer’s core material and winding configuration to optimize performance, especially under the influence of the DC component present in the circuit.

Setting R2 to achieve a collector current of 300mA is crucial for maintaining the longevity of the fluorescent lamp. This current setting ensures that the lamp operates efficiently without excessive wear on the cathodes. The gradual degradation of the cathode coating can lead to reduced performance and lifespan, which is a common issue in fluorescent lamps subjected to non-ideal operating conditions.

In terms of efficiency, the circuit's reliance on a mains transformer is a significant drawback. Operating outside the intended frequency range can lead to core saturation, further diminishing the efficiency of power transfer to the lamp. Consequently, the lamp may not achieve its rated power output of 4W, resulting in lower brightness levels. The use of a push-pull converter with a ferrite transformer is recommended for improved efficiency and brightness. This approach allows for high-frequency operation, which is more suitable for low-voltage applications, and includes filament windings that preheat the cathodes, enhancing the startup performance of the fluorescent tube.

Overall, this circuit represents a basic implementation for driving a fluorescent lamp from a low-voltage supply, with considerations for longevity and efficiency that can be improved through alternative designs.This is a simple 4 W fluorescent lamp driver circuit that can be operated from a 12 V supply. The first part of the circuit includes a NE555 timer IC wired as an astable multivibrator. The output pulses from the IC are amplified by the transistor Q1. The transformer steps up the collector voltage to around 1KVto drive the fluorescent lamp. Before usi ng the circuit, set the R2 at full resistance and switch on the supply, now adjust R2 so that the collector current is 300mA (use a multimeter) and this is the optimum setting for the lamp. Operating the lamp in this setting will give a better life. First, the tube is being started with cold cathodes. Tube life will be shortened as the cathode coating is gradually stripped. This isn`t just a feature of this circuit, but all those cheap battery operated torches having tubes with blackened ends.

Incidentally, as there is a DC component present in the tube supply because of the single ended drive to the transformer, one end of the tube will wear out before the other. Because of the low efficiency of using a mains transformer (operating outside intended frequency range and with the interleaved core laminations saturating because of the DC component), the tube will not receive full 4W of power.

Besides, 300mA @ 12V is only 3. 6W. Therefore, it will not be as bright as one operated from the mains. A push pull converter, running at high frequency, using a ferrite transformer, and having filament windings to warm to cathodes is the best way to operate fluorescent tubes from low voltage DC. 🔗 External reference

This circuit employs a NE555 timer IC configured as an astable multivibrator to generate a square wave output, which is essential for driving the fluorescent lamp. The frequency of oscillation can be adjusted by varying the resistors and capacitors connected to the NE555, allowing for fine-tuning of the output pulses. The transistor Q1 serves as an amplifier to boost the output from the NE555, supplying sufficient current to the transformer.

The transformer is a critical component, designed to step up the voltage from the collector of Q1 to approximately 1kV, which is necessary for igniting and sustaining the discharge in the fluorescent lamp. The design must consider the transformer’s core material and winding configuration to optimize performance, especially under the influence of the DC component present in the circuit.

Setting R2 to achieve a collector current of 300mA is crucial for maintaining the longevity of the fluorescent lamp. This current setting ensures that the lamp operates efficiently without excessive wear on the cathodes. The gradual degradation of the cathode coating can lead to reduced performance and lifespan, which is a common issue in fluorescent lamps subjected to non-ideal operating conditions.

In terms of efficiency, the circuit's reliance on a mains transformer is a significant drawback. Operating outside the intended frequency range can lead to core saturation, further diminishing the efficiency of power transfer to the lamp. Consequently, the lamp may not achieve its rated power output of 4W, resulting in lower brightness levels. The use of a push-pull converter with a ferrite transformer is recommended for improved efficiency and brightness. This approach allows for high-frequency operation, which is more suitable for low-voltage applications, and includes filament windings that preheat the cathodes, enhancing the startup performance of the fluorescent tube.

Overall, this circuit represents a basic implementation for driving a fluorescent lamp from a low-voltage supply, with considerations for longevity and efficiency that can be improved through alternative designs.This is a simple 4 W fluorescent lamp driver circuit that can be operated from a 12 V supply. The first part of the circuit includes a NE555 timer IC wired as an astable multivibrator. The output pulses from the IC are amplified by the transistor Q1. The transformer steps up the collector voltage to around 1KVto drive the fluorescent lamp. Before usi ng the circuit, set the R2 at full resistance and switch on the supply, now adjust R2 so that the collector current is 300mA (use a multimeter) and this is the optimum setting for the lamp. Operating the lamp in this setting will give a better life. First, the tube is being started with cold cathodes. Tube life will be shortened as the cathode coating is gradually stripped. This isn`t just a feature of this circuit, but all those cheap battery operated torches having tubes with blackened ends.

Incidentally, as there is a DC component present in the tube supply because of the single ended drive to the transformer, one end of the tube will wear out before the other. Because of the low efficiency of using a mains transformer (operating outside intended frequency range and with the interleaved core laminations saturating because of the DC component), the tube will not receive full 4W of power.

Besides, 300mA @ 12V is only 3. 6W. Therefore, it will not be as bright as one operated from the mains. A push pull converter, running at high frequency, using a ferrite transformer, and having filament windings to warm to cathodes is the best way to operate fluorescent tubes from low voltage DC. 🔗 External reference