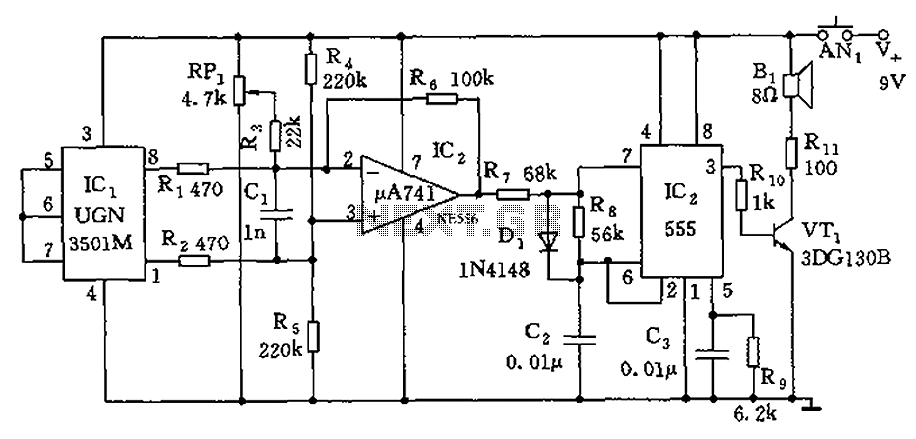

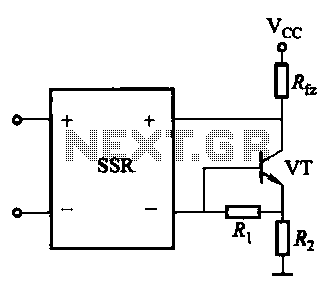

A DC-RRS Application Circuit

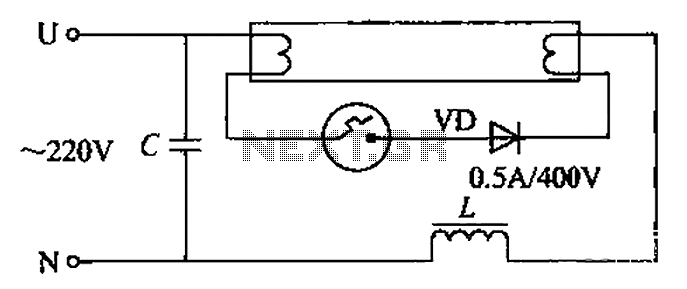

A DC solid-state relay (DC-SSR) driving a high-power load circuit is illustrated in (a) below; the high-power load driving circuit is depicted in (b) below.

The DC solid-state relay (DC-SSR) serves as a crucial component in controlling high-power loads, providing a reliable means of switching without mechanical contacts. The schematic typically includes a control input, which activates the relay, and an output that connects to the load. In the context of high-power applications, the DC-SSR is designed to handle substantial current and voltage levels, making it suitable for various industrial and commercial applications.

The input side of the DC-SSR is typically connected to a low-voltage control signal, which can be sourced from a microcontroller or a control circuit. Upon receiving the control signal, the internal opto-isolator activates the semiconductor switching element, usually a transistor or a triac, allowing current to flow through the output circuit.

The output circuit is connected to the high-power load, which can include motors, heaters, or other heavy-duty electrical devices. It is essential to ensure that the DC-SSR is rated for the specific load current and voltage to prevent overheating and potential failure. Additionally, heat dissipation mechanisms, such as heat sinks or fans, may be incorporated to maintain optimal operating temperatures.

Protection components, such as fuses or circuit breakers, are often included in the circuit design to safeguard against overload conditions. Snubber circuits may also be employed to suppress voltage spikes generated during switching events, thus protecting the relay and the load.

In summary, the integration of a DC solid-state relay in a high-power load circuit provides efficient control and reliability, essential for modern electronic applications requiring robust performance and safety.DC solid state relay (DC-SSR) driving high-power load circuit is shown in (a) below; high power load driving circuit shown in (b) below.

The DC solid-state relay (DC-SSR) serves as a crucial component in controlling high-power loads, providing a reliable means of switching without mechanical contacts. The schematic typically includes a control input, which activates the relay, and an output that connects to the load. In the context of high-power applications, the DC-SSR is designed to handle substantial current and voltage levels, making it suitable for various industrial and commercial applications.

The input side of the DC-SSR is typically connected to a low-voltage control signal, which can be sourced from a microcontroller or a control circuit. Upon receiving the control signal, the internal opto-isolator activates the semiconductor switching element, usually a transistor or a triac, allowing current to flow through the output circuit.

The output circuit is connected to the high-power load, which can include motors, heaters, or other heavy-duty electrical devices. It is essential to ensure that the DC-SSR is rated for the specific load current and voltage to prevent overheating and potential failure. Additionally, heat dissipation mechanisms, such as heat sinks or fans, may be incorporated to maintain optimal operating temperatures.

Protection components, such as fuses or circuit breakers, are often included in the circuit design to safeguard against overload conditions. Snubber circuits may also be employed to suppress voltage spikes generated during switching events, thus protecting the relay and the load.

In summary, the integration of a DC solid-state relay in a high-power load circuit provides efficient control and reliability, essential for modern electronic applications requiring robust performance and safety.DC solid state relay (DC-SSR) driving high-power load circuit is shown in (a) below; high power load driving circuit shown in (b) below.