Acoustic thermometer

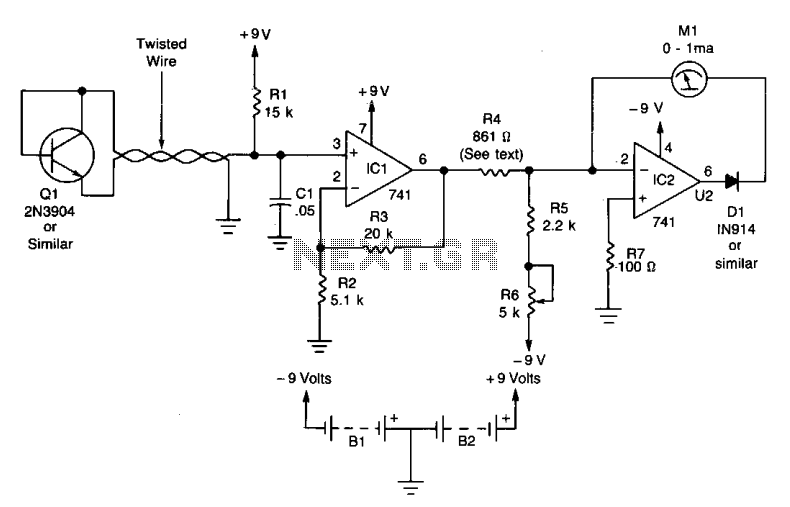

Acoustic thermometry is a precise measurement technique that exploits the relationship between sound wave propagation and temperature variations. In this configuration, the Polaroid ultrasonic material serves as an efficient transducer, capable of converting electrical signals into ultrasonic waves. The choice of a sealed Invar tube is crucial, as Invar's low thermal expansion coefficient ensures minimal distortion due to temperature changes, thus maintaining measurement accuracy.

The transducer operates as a capacitive device, where the insulating disc's movement alters its capacitance in response to the ultrasonic energy emissions. The clock pulse, generated by a timing circuit, plays a dual role: it triggers the mechanical operation of the disc and resets the 74C74 flip-flop, which is essential for timing the ultrasonic transit. The 74C74 flip-flop, a dual D-type flip-flop, captures the time taken for the ultrasonic wave to travel to the end of the tube and back, effectively measuring the round-trip transit time.

The return of the ultrasonic wave to the transducer results in a mechanical displacement, which is detected as a change in capacitance. This change is processed through the circuit, resetting the flip-flop and allowing the next measurement cycle to begin. The relationship between the pulse width and temperature is typically characterized by a linear equation, which can be derived from empirical data. This equation is critical for translating the measured transit time into a temperature reading.

The implementation of this system requires careful calibration and consideration of environmental factors. The monitoring processor must be programmed to interpret the pulse width accurately, ensuring that temperature readings are precise and reliable. This acoustic thermometry method is particularly advantageous in applications where traditional temperature sensors may fail due to extreme conditions, providing a robust alternative for temperature monitoring in critical environments.Acoustic thermometry is used where extremes in operating temperature are encountered, such as in cryogenics and nuclear reactors. The transducer is composed of Polaroid ultrasonic material, mounted at one end of a sealed, 6-in long Invar tube.

The medium inside the tube is dry air. The transducer can be considered a capacitor, composed

of an insulating disc with conductive coating on each side. Each clock pulse causes mechanical movement of the disc, and ultrasonic energy is emitted. The clock pulse simultaneously resets the 74C74 output flip-flop. The ultrasonic energy travels down the tube, bounces off the far end, and returns to the transducer, causing mechanical displacement of the transducer. This shifts the transducer capacitance, resetting the 74C74 through A2 and C1. The 74C74 output pulse represents the transit time down the tube and it varies with the temperature, according to the equation: The pulse width (time between set and reset) can be converted into desired temperature information with a monitoring processor.

Linear Technology. Linear Applications Handbook 1990. p AN7-5,