Arduino Controlled Pneumatic Servo

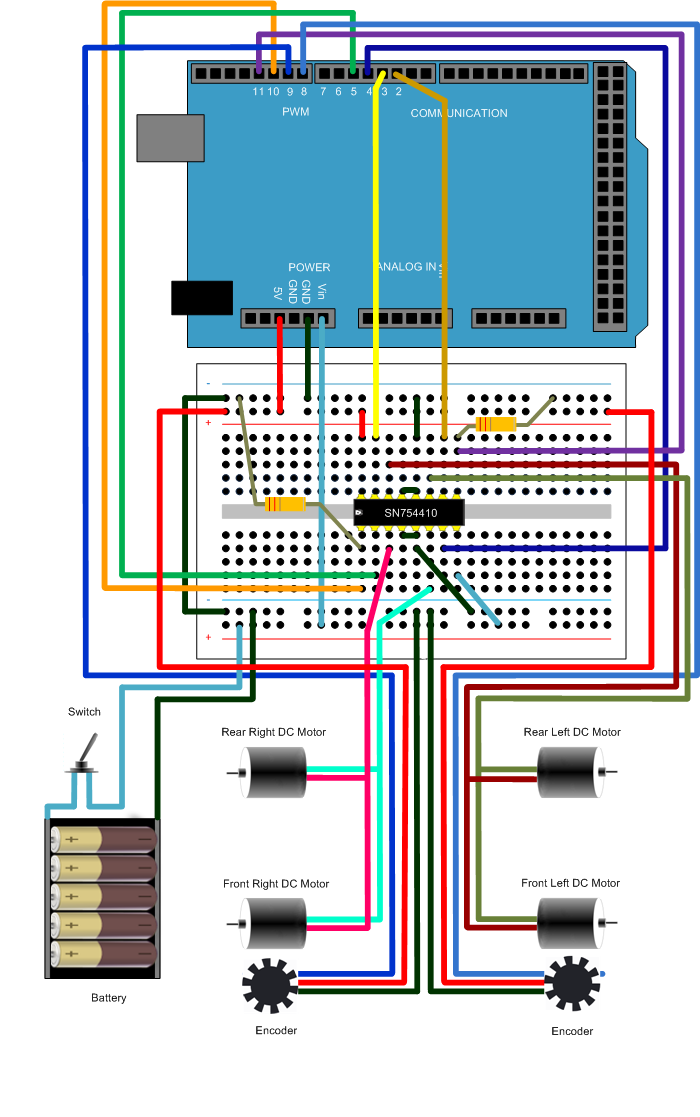

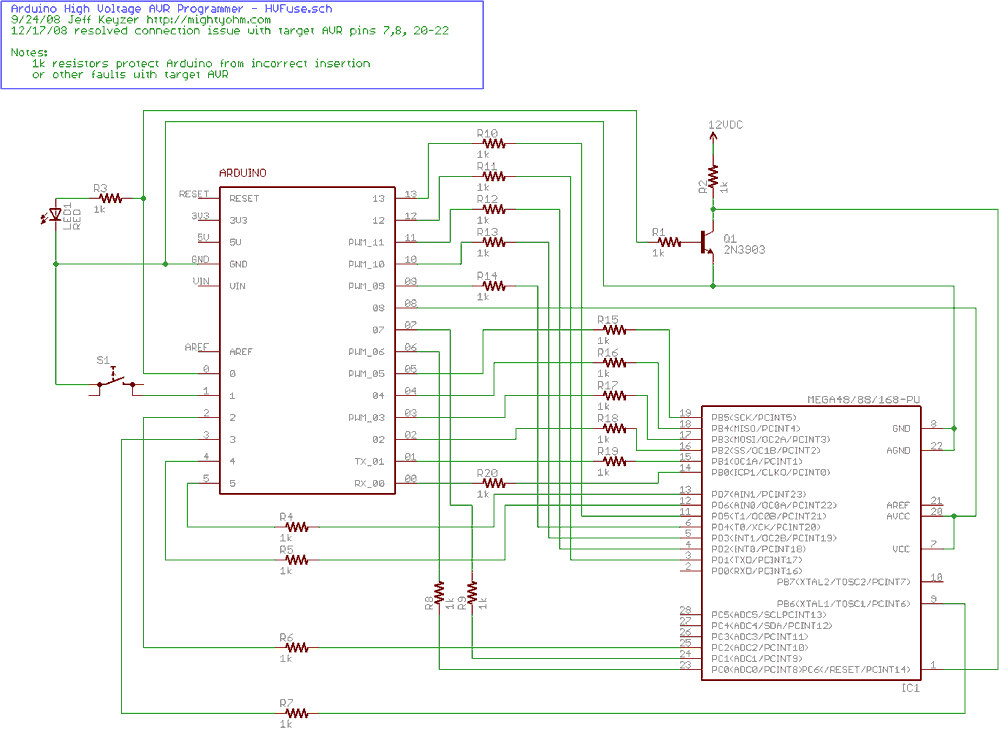

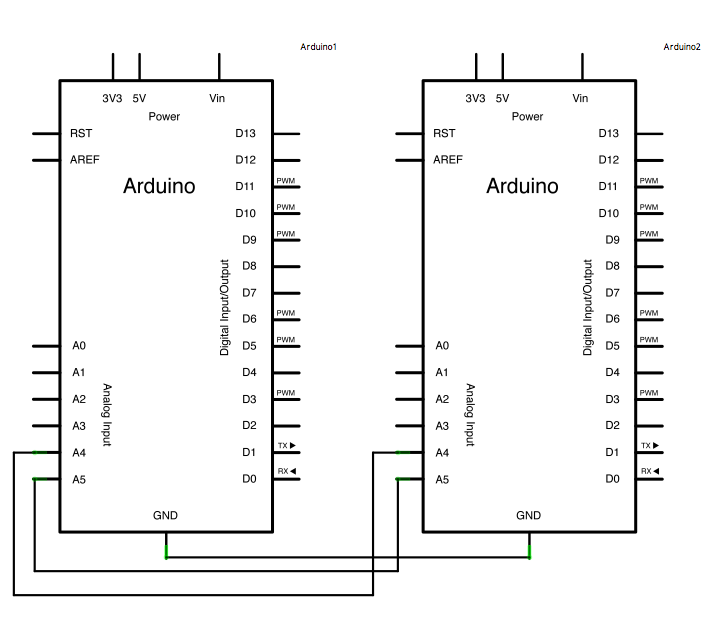

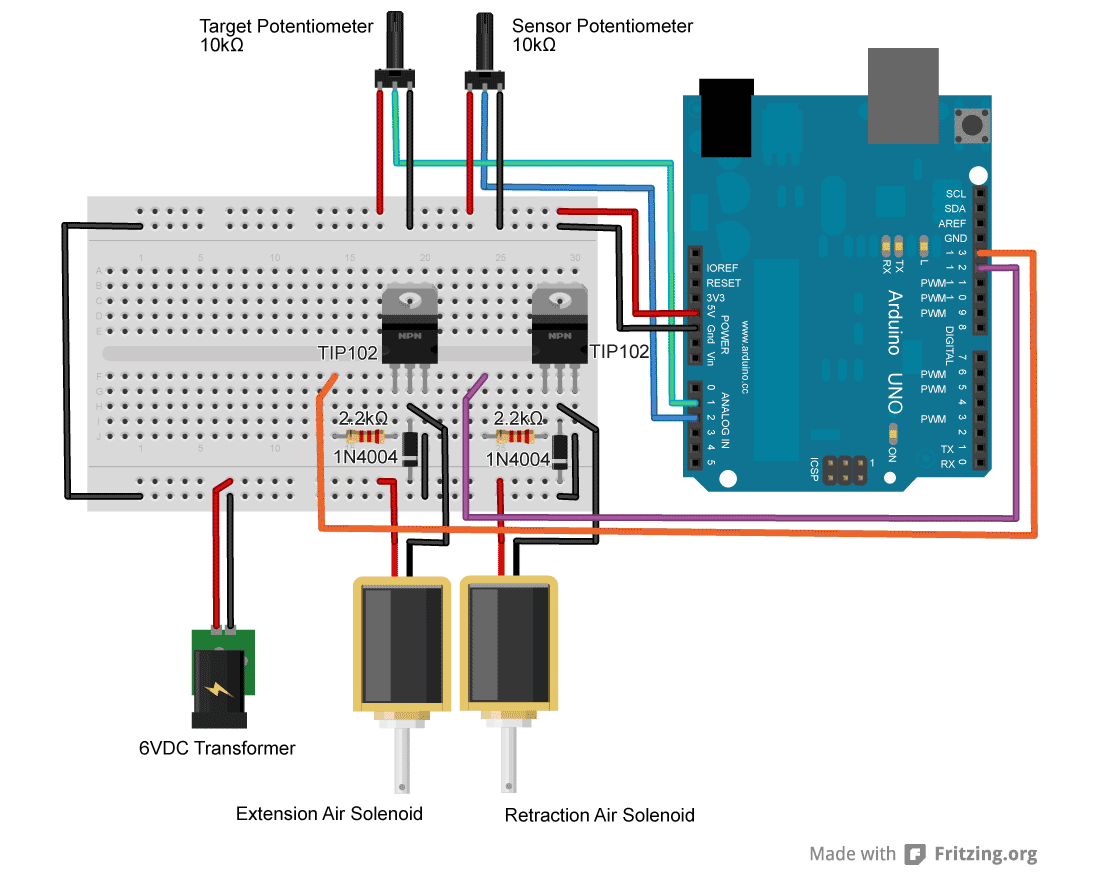

For an upcoming project, a pneumatic ram with a closed-loop control system was required to achieve precise positioning. Due to budget constraints, an off-the-shelf solution was not feasible, prompting the assembly of a custom system using an Arduino, a couple of air solenoid valves, and a pair of potentiometers. The system operates by designating one potentiometer as the target and the other as the position sensor mounted on the ram. The Arduino code compares the two potentiometer readings to determine the necessary direction for the ram to move in order to align with the target. It then activates the solenoid valves in a manner that enables this movement. Once the readings match, both valves are activated simultaneously, effectively locking the ram in position. The target potentiometer can be substituted with any analog input. The hardware setup includes a pair of Clippard mouse valves and an Arduino UNO. These valves exhibit a response time of 10 ms and low power consumption, requiring a transistor and diode for connection to the Arduino, as detailed in solenoid tutorials. The pneumatic ram is double-acting. Optimal performance is achieved with an adjustable inline flow restrictor in the air supply line, allowing for fine-tuning of the fill rate to minimize erratic movements. A notable feature of this design involves attaching a wheel to the knob of one potentiometer, with a string wrapped around it and secured to the ram's end. As the ram extends, it pulls the string, causing the potentiometer to rotate, thereby providing the ram's position. A second string, equipped with a spring, is utilized to roll the wheel back and maintain tension. To determine the wheel's diameter, the ram's stroke length is multiplied by π to find the radius. It is important to consider that the potentiometer may not rotate a full 360 degrees; in this instance, it rotated 270 degrees, which should be factored into the design calculations. It is advisable to create the wheel slightly oversized to prevent potential damage to the potentiometer or string when the ram reaches its limits. In this case, the wheel was constructed from birch plywood, featuring a groove turned on a lathe to guide the string.

The pneumatic ram control system described above integrates several key components that work together to achieve precise positioning. The Arduino acts as the central controller, processing input from the potentiometers and controlling the solenoid valves based on the feedback received. The use of double-acting pneumatic rams enables movement in both directions, which is essential for applications requiring accurate positioning.

The Clippard mouse valves are selected for their quick response time and low power consumption, making them ideal for this application. The connection of these valves to the Arduino is facilitated through a transistor and diode, which serve to manage the current and protect the Arduino from potential back EMF generated when the valves are activated.

The inclusion of an adjustable flow restrictor is crucial for fine-tuning the pneumatic system's response. This component allows for the regulation of air flow into the ram, which can significantly affect the speed and responsiveness of the system. By adjusting the flow restrictor, the user can mitigate any erratic movements caused by sudden changes in pressure.

The innovative use of a wheel attached to the potentiometer's knob is a clever mechanical solution to track the position of the ram accurately. This method converts linear motion into rotational motion, allowing the potentiometer to provide precise feedback to the Arduino. The spring-loaded string mechanism ensures that the system remains taut, preventing slack that could lead to inaccurate readings.

When designing the wheel, careful consideration must be given to its size in relation to the potentiometer's range of motion. An oversized wheel can result in a loss of resolution, while an undersized one can lead to mechanical failure. The use of birch plywood for the wheel construction provides a balance of strength and weight, ensuring durability while maintaining the necessary sensitivity for accurate position tracking.

Overall, this custom pneumatic ram control system exemplifies an effective blend of electronic and mechanical engineering principles, resulting in a cost-effective solution for precise positioning in pneumatic applications.For an upcoming project I needed a pneumatic ram with a closed loop control system so I could position it accurately. Didn`t have the budget for an off the shelf solution, so I bodged one together with an ardunio, a couple air solenoid valves, and a pair of potentiometers.

How it works is one potentiometer is the target while the other is mounted to the ram. The arduino code compares the two, figures out the direction that the ram needs to move to match them up, it then cycles the solenoid valves on and off accordingly. Once the values match, it turns both valves on, more or less locking the ram in place. The target pot can also be replaced with any analog input. For the rest of the hardware I am using a pair of clippard mouse valves and an arduino UNO. The valves work well, 10ms response time and very low power consumption you need a transistor and diode to hook them up to the Arduino, look up the solenoid tutorial.

The ram is a double acting one. Also It works best if you have an adjustable inline flow restrictor on the incoming air stream. It allows you to fine tune the rate of fill so the servo is less twitchy. The big secret on this was to mount a wheel onto the knob of one potentiometer, this wheel has a string wrapped around it that is tied to the end of the ram. When the ram extends, it pulls the string, spins the pot and tada you now have the rams position. You need a second string with a spring attached to roll the wheel back and keep everything taut. To work out the diameter of the wheel just take your rams stroke and multiply by PI to get your radius.

Keep in mind that your pot might not turn 360 degrees, mine was 270 so factor that into your calculations. Best to make it a bit oversize anyway, worst case is that you lose some resolution if its too large, if its too small the ram will destroy the pot or break the string when it runs out of room.

In this case the wheel is made of birch plywood, with a groove turned into it on the lathe to guide the string. 🔗 External reference

The pneumatic ram control system described above integrates several key components that work together to achieve precise positioning. The Arduino acts as the central controller, processing input from the potentiometers and controlling the solenoid valves based on the feedback received. The use of double-acting pneumatic rams enables movement in both directions, which is essential for applications requiring accurate positioning.

The Clippard mouse valves are selected for their quick response time and low power consumption, making them ideal for this application. The connection of these valves to the Arduino is facilitated through a transistor and diode, which serve to manage the current and protect the Arduino from potential back EMF generated when the valves are activated.

The inclusion of an adjustable flow restrictor is crucial for fine-tuning the pneumatic system's response. This component allows for the regulation of air flow into the ram, which can significantly affect the speed and responsiveness of the system. By adjusting the flow restrictor, the user can mitigate any erratic movements caused by sudden changes in pressure.

The innovative use of a wheel attached to the potentiometer's knob is a clever mechanical solution to track the position of the ram accurately. This method converts linear motion into rotational motion, allowing the potentiometer to provide precise feedback to the Arduino. The spring-loaded string mechanism ensures that the system remains taut, preventing slack that could lead to inaccurate readings.

When designing the wheel, careful consideration must be given to its size in relation to the potentiometer's range of motion. An oversized wheel can result in a loss of resolution, while an undersized one can lead to mechanical failure. The use of birch plywood for the wheel construction provides a balance of strength and weight, ensuring durability while maintaining the necessary sensitivity for accurate position tracking.

Overall, this custom pneumatic ram control system exemplifies an effective blend of electronic and mechanical engineering principles, resulting in a cost-effective solution for precise positioning in pneumatic applications.For an upcoming project I needed a pneumatic ram with a closed loop control system so I could position it accurately. Didn`t have the budget for an off the shelf solution, so I bodged one together with an ardunio, a couple air solenoid valves, and a pair of potentiometers.

How it works is one potentiometer is the target while the other is mounted to the ram. The arduino code compares the two, figures out the direction that the ram needs to move to match them up, it then cycles the solenoid valves on and off accordingly. Once the values match, it turns both valves on, more or less locking the ram in place. The target pot can also be replaced with any analog input. For the rest of the hardware I am using a pair of clippard mouse valves and an arduino UNO. The valves work well, 10ms response time and very low power consumption you need a transistor and diode to hook them up to the Arduino, look up the solenoid tutorial.

The ram is a double acting one. Also It works best if you have an adjustable inline flow restrictor on the incoming air stream. It allows you to fine tune the rate of fill so the servo is less twitchy. The big secret on this was to mount a wheel onto the knob of one potentiometer, this wheel has a string wrapped around it that is tied to the end of the ram. When the ram extends, it pulls the string, spins the pot and tada you now have the rams position. You need a second string with a spring attached to roll the wheel back and keep everything taut. To work out the diameter of the wheel just take your rams stroke and multiply by PI to get your radius.

Keep in mind that your pot might not turn 360 degrees, mine was 270 so factor that into your calculations. Best to make it a bit oversize anyway, worst case is that you lose some resolution if its too large, if its too small the ram will destroy the pot or break the string when it runs out of room.

In this case the wheel is made of birch plywood, with a groove turned into it on the lathe to guide the string. 🔗 External reference