arduino freertos fan rpm video

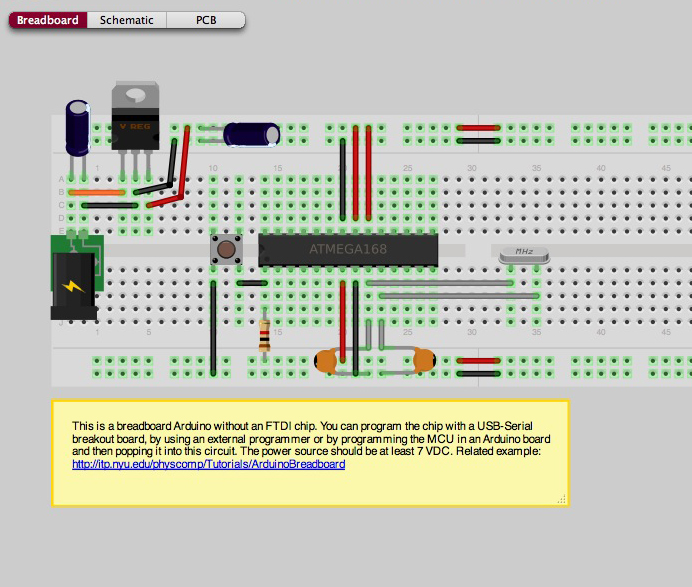

An Arduino is used to measure the rotational speed of a basic computer fan. This project was part of a series of YouTube videos created during a Master's program in Computer Science, specifically focusing on an embedded systems programming course that included some electronics. Although the schematics for the project are not available, the source code is provided. This Arduino sketch utilizes an open-source Timer library. The code involves three main processes: an interrupt service routine (ISR) triggered by the falling edge of the infrared (IR) input whenever a fan blade passes the sensor, and a timer routine attached to a high-speed timer that calculates the RPM based on the number of fan blades detected in one second. The project includes additional components such as a thermistor temperature sensor and an opto-isolated pulse-width-modulated speed controller. The software is based on FreeRTOS for Arduino, with the opto-coupler separating the low voltage Arduino digital I/O from the higher voltage powering the board and fan. The system employs a CNY 75B opto-coupler, requiring a large bias resistance to maintain switching mode. A 100K ohm resistor is used for the IR transistor, and a current-limiting resistor for the IR LED is created with two 47 ohm resistors in series. Although using a 12V fan with a 7.5V power source is not ideal, it functions adequately. The current for the NPN transistor's base is affected by the lower voltage, necessitating different resistances. A 4.7k ohm resistor is placed in parallel with a 10k ohm resistor to enhance the fan's response time. The system software is built on FreeRTOS, wrapped in a C++ layer, where tasks inherit from a task class that includes wrappers for task functions. Additionally, a class wraps the configuration of Timer 2 as a PWM output, driving pin 3. A global override of the new operator is implemented to call pvPortMalloc from FreeRTOS, along with dummy overrides for certain C++ runtime functions. The setup method initializes all tasks and configures hardware, invoking the FreeRTOS Scheduler. If an error occurs, it defaults to the original Arduino sketch loop method, which provides a distinct LED pattern for error indication. The stability of the software varies based on the order of task creation in FreeRTOS, and the provided version is a result of extensive trial and error. Changes to stack sizes, queue sizes, or task order are not recommended due to potential instability.

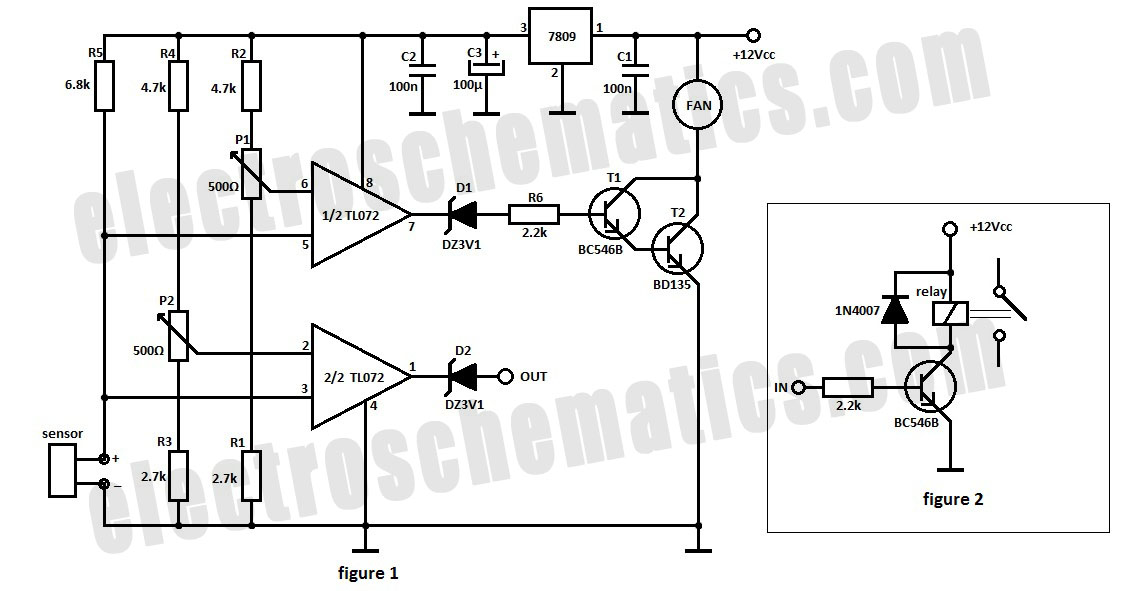

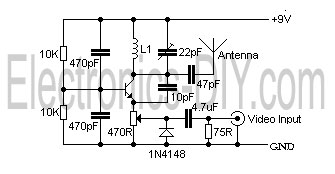

The circuit design for this Arduino-based fan speed measurement system incorporates several critical elements that facilitate effective operation. At its core, the Arduino microcontroller serves as the processing unit, interfacing with an IR sensor to detect the passage of fan blades. The IR sensor is connected to a digital input pin on the Arduino, configured to trigger an interrupt on the falling edge of the signal. This interrupt service routine (ISR) is essential for accurately counting the number of rotations per minute (RPM) by registering each blade that passes the sensor.

To enhance functionality, a thermistor is included in the circuit to monitor the temperature of the environment or the fan itself, providing valuable feedback for potential adjustments in fan speed based on temperature readings. The PWM speed controller, implemented through an opto-coupler, allows for control of the fan speed by modulating the voltage supplied to the fan, effectively adjusting its operational speed based on the calculated RPM.

The choice of components is critical for the performance of the circuit. The CNY 75B opto-coupler is selected for its ability to handle the voltage levels involved, while the biasing resistors ensure that the IR transistor operates in the appropriate mode. The combination of the 100K ohm resistor for the IR transistor and the series resistors for the IR LED is designed to optimize switching performance, minimizing response time and maximizing accuracy in speed measurement.

The software architecture built on FreeRTOS allows for multitasking capabilities, with each task performing specific operations such as reading the IR sensor, updating the RPM calculation, and controlling the fan speed. This structured approach not only enhances the efficiency of the system but also provides a framework for future expansions or modifications, such as adding additional sensors or integrating more complex control algorithms.

In summary, this Arduino-based project effectively combines hardware and software elements to create a robust system for measuring and controlling the speed of a computer fan, demonstrating the principles of embedded systems design and the integration of electronic components for practical applications.An Arduino measuring the rotational speed of a basic computer fan. It was one of a number of YouTube videos I did as I was studying for a Masters in Computer Science. This particular module was an embedded systems programming course, with a bit of electronics thrown in. Here`s the video: I was recently asked if the schematics were available for this video. Unfortunately I was unable to locate the schematics as shown in the video, however I do have the source code. This is a simple Arduino Sketch that uses an open source Timer` library. You can download the fan-rpm-sketch source code. When reading this source code please keeping in mind that there are three processes going on: b) IR ISR this interrupt routine is configured to be triggered by the falling edge of the IR input i. e. whenever the leading (or falling, I forget which) fan blade edge passes the sensor c) A Timer routine that is attached to a high speed timer and called every second to calculate the RPM value extrapolated from the number of fins seen that second.

The difference between the two is the addition of two modules to the layout the thermistor temperature sensor, and the opto-isolated pulse-width-modulated speed controller. On the software side, we now use FreeRTOS on Arduino. The use of an opto-coupler is separates the low voltage Arduino digital IO from the slightly higher voltage used to power the Arduino board and the Fan.

Potentially any voltage is supported up to the limits of the CNY 75B part. The IR transistor from radio shack required a large bias resistance to place it in switching` mode rather than amplification mode. A 100K ohm resistor was chosen. An approximate 100 ohm current limiting resistance for the IR LED was provided through two 47ohm resistors in serial.

Using the 12V fan in conjunction with a 7. 5V power source is not optimal but it works. The current required to feed the base of the NPN transistor is obviously changed by the lowered voltage, so the resistances used needed to be different. A 4. 7k ohm resistor was placed in parallel with a 10k ohm resistor which appears to provide a faster response from the fan ( I assume due to lowered switch time of the NPN transistor ).

The system software is built upon FreeRTOS but is wrapped in a C+ layer. All tasks inherit from a task class that provides wrappers around functions applicable to tasks, including creation, stack and priority configuration, and the ability to invoke a derived (virtual) method that is the actual task code provided by the implementor of the derived class. In addition to tasks, there is one other class to wrap the configuration of timer 2 as a PWM output. The combination of timer 2 and output compare B means that we are driving pin 3 as the PWM output. However, it needed to implement a global override of the new operator to call pvPortMalloc the FreeRTOS implementation.

In addition I had to place dummy overrides for pure virtual and guard C+ runtime implementation functions. The original setup method is used to both initialize all tasks in the system configure the hardware to some base state, and then invoke the FreeRTOS Scheduler.

If something goes wrong, it falls through to the original arduino sketch loop method, which is implemented to provide a distinct LED pattern so that this error condition can be seen. After implementing the C+ layer, however, it became readily apparent that something was wrong, as the stability of the software was variable depending on the order in which tasks were created, whether they were created in FreeRTOS.

What is provided is a working version, but only after much trial and error. Changes to stack sizes, queue sizes, serial debug messages, adding of tasks, or changing the order of tasks and hardware initialization is not recommended! I suspect but cannot be sure that the combination of heap, stack, and static allocations c 🔗 External reference

The circuit design for this Arduino-based fan speed measurement system incorporates several critical elements that facilitate effective operation. At its core, the Arduino microcontroller serves as the processing unit, interfacing with an IR sensor to detect the passage of fan blades. The IR sensor is connected to a digital input pin on the Arduino, configured to trigger an interrupt on the falling edge of the signal. This interrupt service routine (ISR) is essential for accurately counting the number of rotations per minute (RPM) by registering each blade that passes the sensor.

To enhance functionality, a thermistor is included in the circuit to monitor the temperature of the environment or the fan itself, providing valuable feedback for potential adjustments in fan speed based on temperature readings. The PWM speed controller, implemented through an opto-coupler, allows for control of the fan speed by modulating the voltage supplied to the fan, effectively adjusting its operational speed based on the calculated RPM.

The choice of components is critical for the performance of the circuit. The CNY 75B opto-coupler is selected for its ability to handle the voltage levels involved, while the biasing resistors ensure that the IR transistor operates in the appropriate mode. The combination of the 100K ohm resistor for the IR transistor and the series resistors for the IR LED is designed to optimize switching performance, minimizing response time and maximizing accuracy in speed measurement.

The software architecture built on FreeRTOS allows for multitasking capabilities, with each task performing specific operations such as reading the IR sensor, updating the RPM calculation, and controlling the fan speed. This structured approach not only enhances the efficiency of the system but also provides a framework for future expansions or modifications, such as adding additional sensors or integrating more complex control algorithms.

In summary, this Arduino-based project effectively combines hardware and software elements to create a robust system for measuring and controlling the speed of a computer fan, demonstrating the principles of embedded systems design and the integration of electronic components for practical applications.An Arduino measuring the rotational speed of a basic computer fan. It was one of a number of YouTube videos I did as I was studying for a Masters in Computer Science. This particular module was an embedded systems programming course, with a bit of electronics thrown in. Here`s the video: I was recently asked if the schematics were available for this video. Unfortunately I was unable to locate the schematics as shown in the video, however I do have the source code. This is a simple Arduino Sketch that uses an open source Timer` library. You can download the fan-rpm-sketch source code. When reading this source code please keeping in mind that there are three processes going on: b) IR ISR this interrupt routine is configured to be triggered by the falling edge of the IR input i. e. whenever the leading (or falling, I forget which) fan blade edge passes the sensor c) A Timer routine that is attached to a high speed timer and called every second to calculate the RPM value extrapolated from the number of fins seen that second.

The difference between the two is the addition of two modules to the layout the thermistor temperature sensor, and the opto-isolated pulse-width-modulated speed controller. On the software side, we now use FreeRTOS on Arduino. The use of an opto-coupler is separates the low voltage Arduino digital IO from the slightly higher voltage used to power the Arduino board and the Fan.

Potentially any voltage is supported up to the limits of the CNY 75B part. The IR transistor from radio shack required a large bias resistance to place it in switching` mode rather than amplification mode. A 100K ohm resistor was chosen. An approximate 100 ohm current limiting resistance for the IR LED was provided through two 47ohm resistors in serial.

Using the 12V fan in conjunction with a 7. 5V power source is not optimal but it works. The current required to feed the base of the NPN transistor is obviously changed by the lowered voltage, so the resistances used needed to be different. A 4. 7k ohm resistor was placed in parallel with a 10k ohm resistor which appears to provide a faster response from the fan ( I assume due to lowered switch time of the NPN transistor ).

The system software is built upon FreeRTOS but is wrapped in a C+ layer. All tasks inherit from a task class that provides wrappers around functions applicable to tasks, including creation, stack and priority configuration, and the ability to invoke a derived (virtual) method that is the actual task code provided by the implementor of the derived class. In addition to tasks, there is one other class to wrap the configuration of timer 2 as a PWM output. The combination of timer 2 and output compare B means that we are driving pin 3 as the PWM output. However, it needed to implement a global override of the new operator to call pvPortMalloc the FreeRTOS implementation.

In addition I had to place dummy overrides for pure virtual and guard C+ runtime implementation functions. The original setup method is used to both initialize all tasks in the system configure the hardware to some base state, and then invoke the FreeRTOS Scheduler.

If something goes wrong, it falls through to the original arduino sketch loop method, which is implemented to provide a distinct LED pattern so that this error condition can be seen. After implementing the C+ layer, however, it became readily apparent that something was wrong, as the stability of the software was variable depending on the order in which tasks were created, whether they were created in FreeRTOS.

What is provided is a working version, but only after much trial and error. Changes to stack sizes, queue sizes, serial debug messages, adding of tasks, or changing the order of tasks and hardware initialization is not recommended! I suspect but cannot be sure that the combination of heap, stack, and static allocations c 🔗 External reference