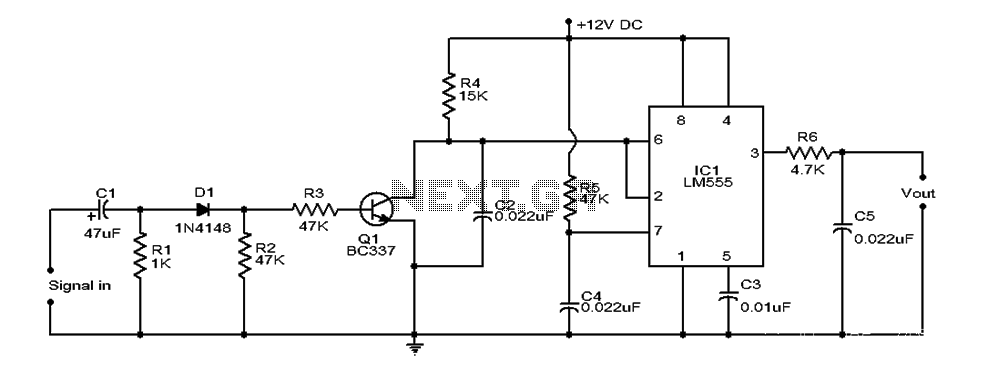

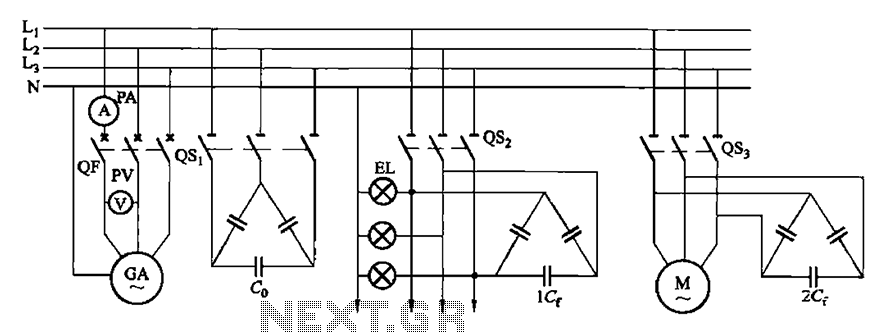

Asynchronous power wiring diagram

A three-phase squirrel cage induction motor is driven by a prime mover (such as diesel engines) and has asynchronous motor stator windings connected to the output end along with several capacitors for excitation power, enabling it to produce three-phase alternating current. This configuration is referred to as asynchronous power generation mode. In this setup, the self-excited capacitors are divided into two sections: the main capacitor (C0), which is responsible for producing the rated voltage at no load, and the additional capacitance or adjustment capacitors (LCf, 20), which maintain the rated voltage under full load conditions. Suitable capacitors for this application include metallized film capacitors or self-healing shunt capacitors, such as the BCMJ and BFF series, with a rated voltage of at least 400V. The capacitance of the main capacitor can be estimated using the following equations: for a generator rated at 380V, Cc is approximately 14.5510 (µF), and for a generator rated at 220V, Co is approximately 2510 (µF), where Io represents the no-load current of the asynchronous motor in amperes.

The three-phase squirrel cage induction motor operates by converting electrical energy into mechanical energy through electromagnetic induction. The prime mover, such as a diesel engine, provides the necessary rotational force to the rotor of the motor. The stator windings generate a rotating magnetic field that induces current in the rotor, facilitating the motor's operation.

In asynchronous power generation mode, the motor operates above its synchronous speed, effectively functioning as a generator. The output of three-phase alternating current is achieved by connecting the stator windings to a load and utilizing capacitors to manage the excitation and voltage levels. The main capacitor (C0) plays a critical role by ensuring that the generator produces the rated voltage under no-load conditions, while the additional capacitors (LCf, 20) are essential for maintaining voltage stability when the motor is under full load.

The selection of capacitors is crucial for the system's performance. Metallized film capacitors or self-healing shunt capacitors are preferred due to their reliability and ability to withstand high voltage levels. The specified minimum rated voltage of 400V ensures that the capacitors can handle the electrical stress without failure.

To size the main capacitor accurately, the equations provided serve as a guideline, allowing engineers to calculate the required capacitance based on the generator's rated voltage and the no-load current. This ensures optimal performance and efficiency of the asynchronous power generation system, contributing to its effectiveness in various applications, including renewable energy systems and backup power solutions.A three-phase squirrel cage induction motor by a prime mover (such as diesel engines, etc.) drag and asynchronous motor stator windings connected to the outlet end and a number of capacitors as excitation power, will be able to output three-phase alternating current. This is called asynchronous power generation mode. Asynchronous power wiring shown in Figure 7-1. Self-excited capacitor is divided into two parts: - Part of the generator to produce the rated voltage at no load, called the main capacitor (c0); the other part of the generator and the load to full load rated voltage kept constant, called the additional capacitance or adjustment capacitors (lCf, 20). Capacitors can be used metallized film capacitors or self-healing shunt capacitors, such as BCMJ, BFF series, the rated voltage is not less than 400V.

The capacitance of the main capacitor can be estimated by the following equation: When used for a rated voltage of 380V generator Cc a 14.5510 (p, F) when used for a rated voltage of 220V generator Co 2510 (and F) where, Io for the restructuring of the asynchronous motor no-load current, a.

The three-phase squirrel cage induction motor operates by converting electrical energy into mechanical energy through electromagnetic induction. The prime mover, such as a diesel engine, provides the necessary rotational force to the rotor of the motor. The stator windings generate a rotating magnetic field that induces current in the rotor, facilitating the motor's operation.

In asynchronous power generation mode, the motor operates above its synchronous speed, effectively functioning as a generator. The output of three-phase alternating current is achieved by connecting the stator windings to a load and utilizing capacitors to manage the excitation and voltage levels. The main capacitor (C0) plays a critical role by ensuring that the generator produces the rated voltage under no-load conditions, while the additional capacitors (LCf, 20) are essential for maintaining voltage stability when the motor is under full load.

The selection of capacitors is crucial for the system's performance. Metallized film capacitors or self-healing shunt capacitors are preferred due to their reliability and ability to withstand high voltage levels. The specified minimum rated voltage of 400V ensures that the capacitors can handle the electrical stress without failure.

To size the main capacitor accurately, the equations provided serve as a guideline, allowing engineers to calculate the required capacitance based on the generator's rated voltage and the no-load current. This ensures optimal performance and efficiency of the asynchronous power generation system, contributing to its effectiveness in various applications, including renewable energy systems and backup power solutions.A three-phase squirrel cage induction motor by a prime mover (such as diesel engines, etc.) drag and asynchronous motor stator windings connected to the outlet end and a number of capacitors as excitation power, will be able to output three-phase alternating current. This is called asynchronous power generation mode. Asynchronous power wiring shown in Figure 7-1. Self-excited capacitor is divided into two parts: - Part of the generator to produce the rated voltage at no load, called the main capacitor (c0); the other part of the generator and the load to full load rated voltage kept constant, called the additional capacitance or adjustment capacitors (lCf, 20). Capacitors can be used metallized film capacitors or self-healing shunt capacitors, such as BCMJ, BFF series, the rated voltage is not less than 400V.

The capacitance of the main capacitor can be estimated by the following equation: When used for a rated voltage of 380V generator Cc a 14.5510 (p, F) when used for a rated voltage of 220V generator Co 2510 (and F) where, Io for the restructuring of the asynchronous motor no-load current, a.