autonomous car

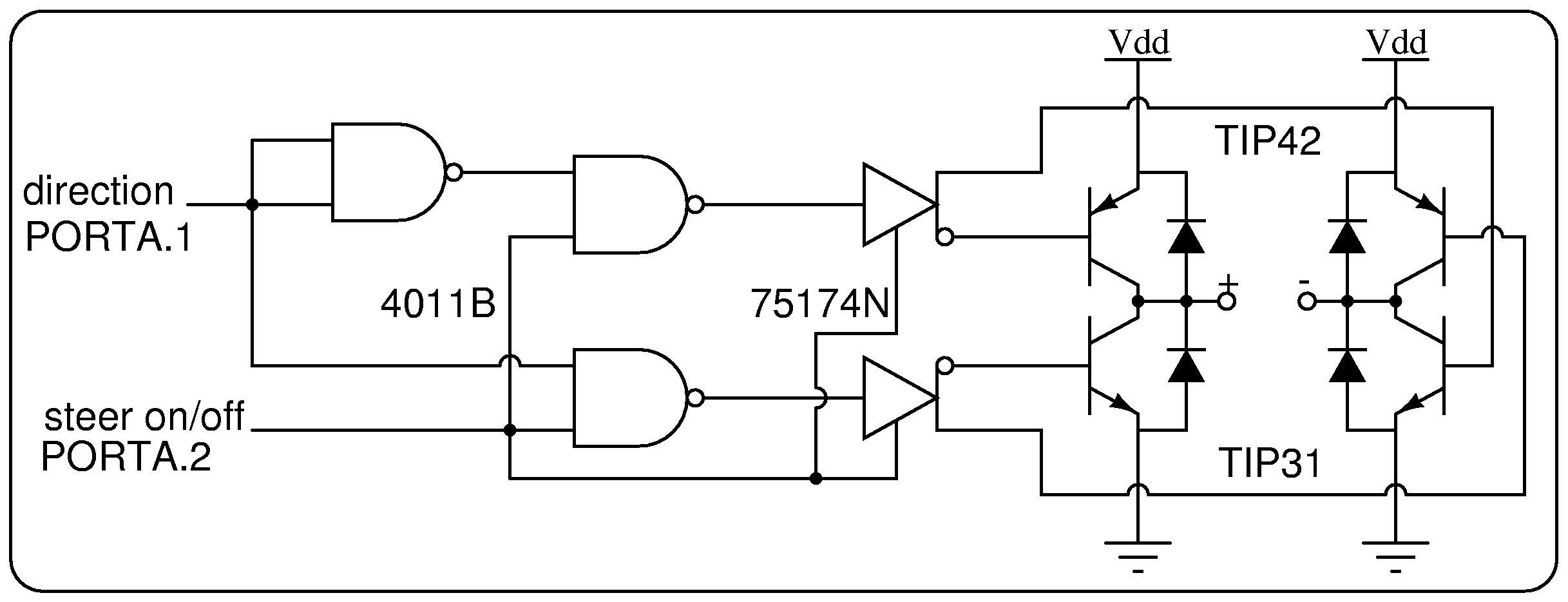

Autonomous vehicles are currently utilized in various manufacturing facilities and are also marketed as toys. In the future, highways may be populated with vehicles that require no user intervention. Although this may not be fully realized, an autonomous vehicle represents an intriguing and practical design challenge. The vehicle employs optical sensors to follow a line on the floor, a method similar to some autonomous vehicles in manufacturing that follow magnetic strips embedded in the factory floor. The adaptability of an optical design is evident, as rerouting the vehicle only necessitates repainting a line. The vehicle utilizes reflective phototransistors to detect the line beneath it. The status of the phototransistors is monitored, and an Atmel 8515 microcontroller controls the vehicle accordingly. If the vehicle detects a minor deviation from the line, it adjusts its path by steering in the correct direction. For more significant deviations, it employs more drastic measures, such as reversing while steering back toward the line until it re-centers itself before continuing on its path. The initial goal of the project was to optimize the vehicle's speed as it navigated the line. This would involve increasing speed with minimal compensation and decreasing speed when more adjustment was required. However, this optimization did not necessitate extensive additional effort beyond the outlined heuristic, as the speed is mechanically regulated by the gradual acceleration of the vehicle in conjunction with direction reversal for substantial corrections. The hardware aspect of the project constituted the majority of the work. To avoid using breadboards for a moving vehicle, which are costly and would require disassembly after demonstration, all circuitry was wire-wrapped. This approach required considerable labor but proved worthwhile. The selected vehicle operates simply with rear-wheel drive, featuring a differential powered by a DC motor. Steering is accomplished by a solenoid instead of a servo, resulting in an "all or nothing" control mechanism, which was found to be acceptable. Two H-bridges were constructed using TIP-31, TIP-3055, and TIP-42 BJTs to supply power to the steering and drive motor. Due to the current demands (with the drive motor and steering solenoid drawing several amps), 20-gauge wire was used for high-current areas of the H-bridges, while 30-gauge wire was employed for the remainder of the circuitry. Schematics of the H-bridges and supporting CMOS logic are provided below. To detect the line, an array of five reflective photo-sensor pairs from Fairchild Semiconductor was mounted just ahead of the front wheels on a threaded rod for easy repositioning. The current through the photo-transistor varies with the intensity detected, but a logic level output is required. An open-loop-gain amplifier constructed with an LMC7111 op-amp was used for this purpose. A trim-pot was included to set the threshold level, and LEDs assisted in calibration. A schematic of the circuit for the photo-sensors is also provided. Given the high current draw from the motor and steering, a separate power supply was designated for the logic, with the logic operating at 6V while the motors functioned at 12V. This separation initially led to some issues, but problems with inductive "kick" from the motor were ultimately avoided.

The autonomous vehicle design described involves a systematic approach to navigating a predefined path using optical sensors and microcontroller technology. The reflective phototransistors serve as the primary sensing mechanism, providing feedback on the vehicle's position relative to the line on the ground. The Atmel 8515 microcontroller processes this feedback and executes control commands to steer the vehicle accordingly. The use of a solenoid for steering introduces a binary control mechanism, which simplifies the steering process but may limit precise maneuverability.

The H-bridge configuration allows for efficient control of the drive motor and steering solenoid, providing the necessary current to enable effective operation. The choice of BJTs for the H-bridge design is appropriate given their ability to handle high current loads while maintaining reliability. The implementation of wire-wrapping for the circuitry ensures a robust construction suitable for the mobile application, minimizing the risk of disconnections that could occur with breadboard setups.

The power supply design, with separate voltages for logic and motor operations, is critical in preventing interference from motor noise that could disrupt the logic operations. The use of an open-loop-gain amplifier to convert the phototransistor output to a logic level is a suitable solution for achieving the necessary signal processing. Calibration through the use of trim-pots and LEDs enhances the system's adaptability to varying environmental conditions.

Overall, this project exemplifies a practical application of electronics and control systems in the development of autonomous vehicles, highlighting the integration of sensors, microcontrollers, and power management in achieving functional and efficient designs.Autonomous vehicles are already in use in many manufacturing facilities, and they are also sold as toys. Perhaps one day, the world`s highways will be filled with cars requiring no user intervention. While we are not there yet, and may never get there, an autonomous vehicle can serve as a very interesting and practical design exercise.

Our vehicle uses optical sensors to follow a line on the floor. Some autonomous vehicles used in manufacturing use a similar concept, following magnetic strips embedded in the factory floor. The versatility of an optical design should be readily apparent, since re-routing the vehicle requires no more than re-painting a line.

Our vehicle uses reflective phototransistors to follow a line on the ground beneath it. The state of the phototransistors is captured, and the car is controlled accordingly by an Atmel 8515 microcontroller. If the car detects a small deviation from the line, it will correct its path by steering in the appropriate direction.

If it detects a large deviation, it will take more "drastic" measures to correct its path: it will back up while steering itself back towards the line until it re-centers itself. It then continues on its path. The original objective for this project was to optimize the car for the speed with which it navigated the line.

To do this, we would have increased the speed when little compensation was needed, and decreased the speed as more was needed. This optimization, however, did not require much more effort on our part than the heuristic outlined above.

This is because the speed is mechanically regulated by the gradual acceleration of the car in balance with the direction reversal for large corrections. The hardware for this project was the bulk of the work. Because we were making a moving vehicle, we decided that it would be best not to have any of the circuitry on breadboards.

Breadboards are also expensive, so we probably would have had to disassemble the car after its demonstration. We therefore chose to wire-wrap all of the circuitry. This required a fair amount of labor, but it was well worth it in the end. The car we selected is fairly simple to operate. It has a rear wheel drive, complete with a differential, which is powered by a DC motor. The steering is not controlled by a servo, but rather by a solenoid. This results in an "all or nothing" control over the steering, but we did not find this to be overly constraining.

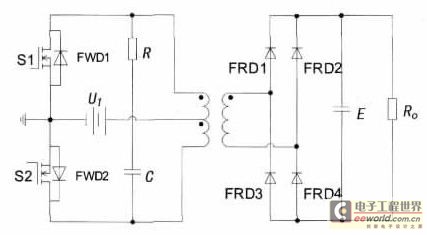

We built two H-bridges using TIP-31, TIP3055, and TIP-42 BJTs to deliver power to the steering and the drive motor. Because of the current requirements (the drive motor and steering solenoid could draw several amps), we used 20-gauge wire for the high-current areas of the H-bridges rather than the 30-gauge wire used for the rest of the circuit.

Schematicsof the H-bridges and supporting CMOS logic appear below. To detect the line, we use an array of five reflective photo-sensor pairs manufactured by Fairchild Semiconductor. We mounted them just ahead of the front wheels on a threaded rod to allow us to reposition them as necessary.

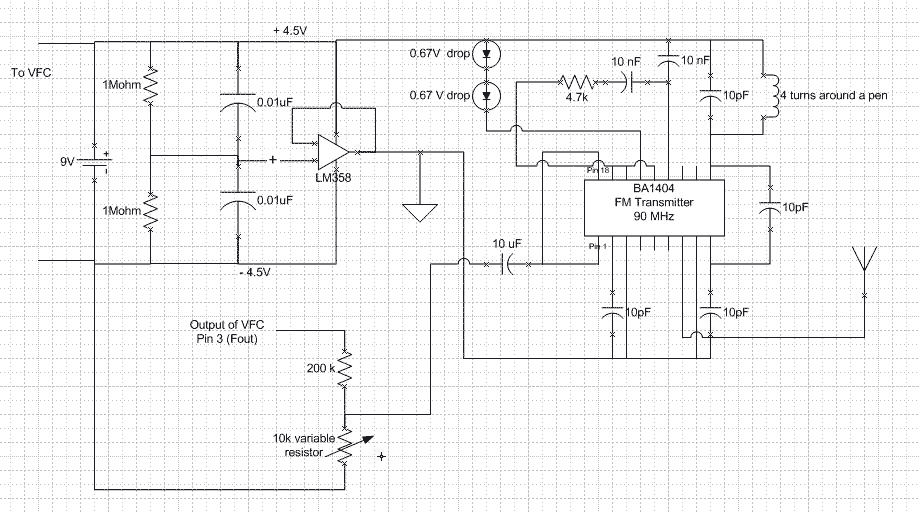

The current through the photo-transistor depends on the intensity it detects, but what we really need is a logic level output. We therefore used an open-loop-gain amplifier made from an LMC7111 op-amp. A trim-pot allowed us to set a threshold level, and LEDs were used to aid in calibration. Aschematicof the circuit used for the photo-sensors appears below. Because of the high current draw from the motor and steering, we decided to use a separate power supply for the logic.

The logic runs on 6V while the car`s motors run on 12V. This initially resulted in some careless bugs, but we seem to have avoided problems with any inductive "kick" from the motor a 🔗 External reference

The autonomous vehicle design described involves a systematic approach to navigating a predefined path using optical sensors and microcontroller technology. The reflective phototransistors serve as the primary sensing mechanism, providing feedback on the vehicle's position relative to the line on the ground. The Atmel 8515 microcontroller processes this feedback and executes control commands to steer the vehicle accordingly. The use of a solenoid for steering introduces a binary control mechanism, which simplifies the steering process but may limit precise maneuverability.

The H-bridge configuration allows for efficient control of the drive motor and steering solenoid, providing the necessary current to enable effective operation. The choice of BJTs for the H-bridge design is appropriate given their ability to handle high current loads while maintaining reliability. The implementation of wire-wrapping for the circuitry ensures a robust construction suitable for the mobile application, minimizing the risk of disconnections that could occur with breadboard setups.

The power supply design, with separate voltages for logic and motor operations, is critical in preventing interference from motor noise that could disrupt the logic operations. The use of an open-loop-gain amplifier to convert the phototransistor output to a logic level is a suitable solution for achieving the necessary signal processing. Calibration through the use of trim-pots and LEDs enhances the system's adaptability to varying environmental conditions.

Overall, this project exemplifies a practical application of electronics and control systems in the development of autonomous vehicles, highlighting the integration of sensors, microcontrollers, and power management in achieving functional and efficient designs.Autonomous vehicles are already in use in many manufacturing facilities, and they are also sold as toys. Perhaps one day, the world`s highways will be filled with cars requiring no user intervention. While we are not there yet, and may never get there, an autonomous vehicle can serve as a very interesting and practical design exercise.

Our vehicle uses optical sensors to follow a line on the floor. Some autonomous vehicles used in manufacturing use a similar concept, following magnetic strips embedded in the factory floor. The versatility of an optical design should be readily apparent, since re-routing the vehicle requires no more than re-painting a line.

Our vehicle uses reflective phototransistors to follow a line on the ground beneath it. The state of the phototransistors is captured, and the car is controlled accordingly by an Atmel 8515 microcontroller. If the car detects a small deviation from the line, it will correct its path by steering in the appropriate direction.

If it detects a large deviation, it will take more "drastic" measures to correct its path: it will back up while steering itself back towards the line until it re-centers itself. It then continues on its path. The original objective for this project was to optimize the car for the speed with which it navigated the line.

To do this, we would have increased the speed when little compensation was needed, and decreased the speed as more was needed. This optimization, however, did not require much more effort on our part than the heuristic outlined above.

This is because the speed is mechanically regulated by the gradual acceleration of the car in balance with the direction reversal for large corrections. The hardware for this project was the bulk of the work. Because we were making a moving vehicle, we decided that it would be best not to have any of the circuitry on breadboards.

Breadboards are also expensive, so we probably would have had to disassemble the car after its demonstration. We therefore chose to wire-wrap all of the circuitry. This required a fair amount of labor, but it was well worth it in the end. The car we selected is fairly simple to operate. It has a rear wheel drive, complete with a differential, which is powered by a DC motor. The steering is not controlled by a servo, but rather by a solenoid. This results in an "all or nothing" control over the steering, but we did not find this to be overly constraining.

We built two H-bridges using TIP-31, TIP3055, and TIP-42 BJTs to deliver power to the steering and the drive motor. Because of the current requirements (the drive motor and steering solenoid could draw several amps), we used 20-gauge wire for the high-current areas of the H-bridges rather than the 30-gauge wire used for the rest of the circuit.

Schematicsof the H-bridges and supporting CMOS logic appear below. To detect the line, we use an array of five reflective photo-sensor pairs manufactured by Fairchild Semiconductor. We mounted them just ahead of the front wheels on a threaded rod to allow us to reposition them as necessary.

The current through the photo-transistor depends on the intensity it detects, but what we really need is a logic level output. We therefore used an open-loop-gain amplifier made from an LMC7111 op-amp. A trim-pot allowed us to set a threshold level, and LEDs were used to aid in calibration. Aschematicof the circuit used for the photo-sensors appears below. Because of the high current draw from the motor and steering, we decided to use a separate power supply for the logic.

The logic runs on 6V while the car`s motors run on 12V. This initially resulted in some careless bugs, but we seem to have avoided problems with any inductive "kick" from the motor a 🔗 External reference