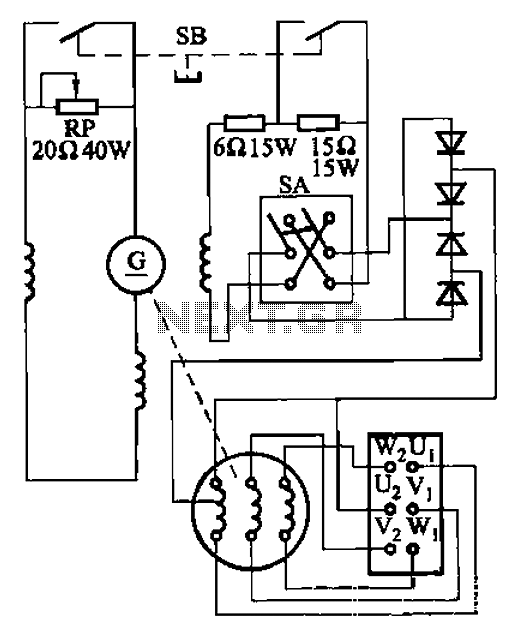

AX3-300-2 DC arc welding machine circuit

The AX3-300-2 DC arc welding machine circuit is part of the AX, AX1, AX3, and AR series of rotary DC arc welding machines. These machines share a similar structural design, featuring a three-integral unit configuration that combines an inverter phase asynchronous motor with a coaxial DC arc welding generator. The AX series welding machines offer a current regulation system with both coarse and fine adjustment capabilities. The coarse adjustment includes three fixed stop positions located in a concave groove on the lid, which allows for movement through the brush holder. Adjusting the brush holder along the steering motor alters the operating current—moving it reduces the current, while moving it in the opposite direction increases the current. Fine tuning is accomplished by manually adjusting the shunt winding resistance via a hand wheel. The AX1 series also includes coarse and fine current regulation, where the coarse adjustment modifies the series excitation winding turns on the line panel, while fine tuning is achieved by adjusting the handwheel, which changes the resistance of the Reed winding transformer groups. The AX3 series features two types of current regulation—coarse and fine—as well. Coarse adjustment is implemented through a single-throw switch with two positions for large and small tokens, while fine tuning is performed by adjusting the brush position using a hand wheel. Additionally, polarity changes can be made using a double-throw switch, which allows for smooth transitions.

The AX3-300-2 DC arc welding machine circuit is engineered for precision and versatility in welding applications. Its three-integral unit design enhances operational efficiency by integrating the motor and generator, facilitating compactness and ease of maintenance. The inverter phase asynchronous motor provides reliable power delivery, ensuring stable arc performance during welding operations.

The current regulation mechanism is a notable feature of this machine, allowing users to tailor the welding output to match specific material requirements and welding conditions. The coarse adjustment system, with its fixed stop positions, provides a straightforward method for achieving significant changes in current levels quickly. This feature is particularly beneficial for initial setup or when switching between different welding tasks that require varying current levels.

For more nuanced control, the fine adjustment allows for precise tuning of the welding current, enabling operators to achieve optimal arc characteristics for different welding materials and thicknesses. The integration of a hand wheel for fine tuning enhances user experience by providing tactile feedback during adjustments.

The dual-functionality of the coarse and fine adjustment systems across the AX series, including the AX1 and AX3 models, demonstrates a commitment to user-friendly design while maintaining high performance. The ability to switch polarity with a double-throw switch further adds to the machine's versatility, allowing for adjustments in welding technique without the need for complex reconfiguration.

Overall, the AX3-300-2 DC arc welding machine circuit exemplifies advanced engineering, combining robust construction with sophisticated control features that cater to the diverse needs of welding professionals.AX3-300-2 DC arc welding machine circuit Rotary DC arc welding machine has AX, AX1, AX3 and AR series. Its structure is basically the same, are made of a three integral unit co nverter phase asynchronous motor and a DC arc welding generator coaxial configuration. AX series DC arc welding machine current regulation has two coarse and fine adjustment. Coarse There are three stop positions, fixed in the lid concave groove, which is moving through the brush holder to achieve. Move along the steering motor brush holder, the operating current is reduced; conversely, the operating current increases.

Fine tuning is to change the shunt winding resistance varistor by hand wheel to achieve. AX1 series DC arc welding machine has a current regulating coarse and fine two kinds. Coarse is by changing the line panel series excitation winding turns to achieve. Fine-tuning is changed by the handwheel and realized Reed winding transformer groups resistance. AX3 series DC arc welding machine has a current regulating coarse and fine two kinds. Coarse There are two block from large and small tokens of single-throw switch to achieve. Fine-tuning by hand wheel moving brush to achieve. Polarity change can flip the down, smooth remember number to achieve double-throw switch.

The AX3-300-2 DC arc welding machine circuit is engineered for precision and versatility in welding applications. Its three-integral unit design enhances operational efficiency by integrating the motor and generator, facilitating compactness and ease of maintenance. The inverter phase asynchronous motor provides reliable power delivery, ensuring stable arc performance during welding operations.

The current regulation mechanism is a notable feature of this machine, allowing users to tailor the welding output to match specific material requirements and welding conditions. The coarse adjustment system, with its fixed stop positions, provides a straightforward method for achieving significant changes in current levels quickly. This feature is particularly beneficial for initial setup or when switching between different welding tasks that require varying current levels.

For more nuanced control, the fine adjustment allows for precise tuning of the welding current, enabling operators to achieve optimal arc characteristics for different welding materials and thicknesses. The integration of a hand wheel for fine tuning enhances user experience by providing tactile feedback during adjustments.

The dual-functionality of the coarse and fine adjustment systems across the AX series, including the AX1 and AX3 models, demonstrates a commitment to user-friendly design while maintaining high performance. The ability to switch polarity with a double-throw switch further adds to the machine's versatility, allowing for adjustments in welding technique without the need for complex reconfiguration.

Overall, the AX3-300-2 DC arc welding machine circuit exemplifies advanced engineering, combining robust construction with sophisticated control features that cater to the diverse needs of welding professionals.AX3-300-2 DC arc welding machine circuit Rotary DC arc welding machine has AX, AX1, AX3 and AR series. Its structure is basically the same, are made of a three integral unit co nverter phase asynchronous motor and a DC arc welding generator coaxial configuration. AX series DC arc welding machine current regulation has two coarse and fine adjustment. Coarse There are three stop positions, fixed in the lid concave groove, which is moving through the brush holder to achieve. Move along the steering motor brush holder, the operating current is reduced; conversely, the operating current increases.

Fine tuning is to change the shunt winding resistance varistor by hand wheel to achieve. AX1 series DC arc welding machine has a current regulating coarse and fine two kinds. Coarse is by changing the line panel series excitation winding turns to achieve. Fine-tuning is changed by the handwheel and realized Reed winding transformer groups resistance. AX3 series DC arc welding machine has a current regulating coarse and fine two kinds. Coarse There are two block from large and small tokens of single-throw switch to achieve. Fine-tuning by hand wheel moving brush to achieve. Polarity change can flip the down, smooth remember number to achieve double-throw switch.