Before power is in the hold state holding brake one circuit

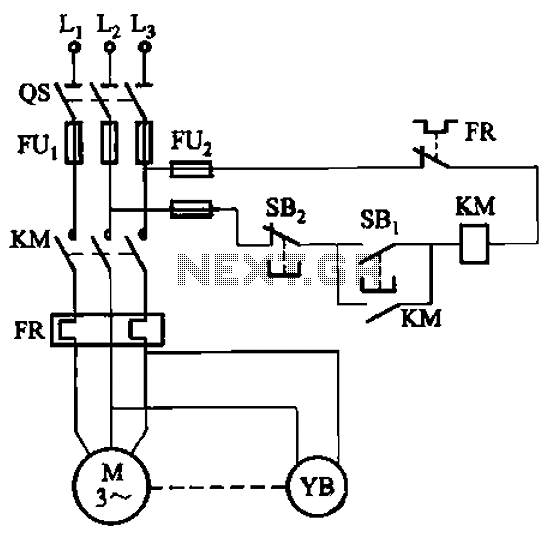

The circuit depicted in Figure 3-121 illustrates the key component of an electromagnetic holding brake, which consists of an electromagnetic brake solenoid primarily made up of two parts: the iron core and the shoe brake components. When power is supplied to the motor, the electromagnetic brake coil (YB) becomes energized, causing the brake lever to move upward. This action disengages the wheel brake, allowing the brake shoes to release and the motor to operate. Conversely, when the power supply to the motor is interrupted (by pressing the stop button SB2), the coil YB loses its power, resulting in the brake shoes being rapidly engaged by the spring force, which quickly halts the motor.

The electromagnetic holding brake circuit operates through a solenoid mechanism that integrates seamlessly with the motor control system. The solenoid, designated as YB, serves as the primary actuator that controls the engagement and disengagement of the brake system. When the motor receives power, the solenoid coil is energized, creating a magnetic field that pulls the armature connected to the brake lever. This action lifts the brake lever, thereby retracting the brake shoes away from the wheel, allowing the motor to run freely.

The system is designed to ensure safety and efficiency. The brake shoes are held in a disengaged position during normal operation, but upon de-energizing the solenoid—typically initiated by the pressing of the stop button (SB2)—the magnetic field collapses. This results in the immediate release of the solenoid's hold on the brake lever, allowing the brake shoes to be forced back into contact with the wheel by a spring mechanism. This rapid engagement of the brake shoes effectively stops the motor, preventing any unintended motion and ensuring a controlled halt.

To enhance the reliability of the system, components such as the solenoid must be rated for the specific voltage and current requirements of the motor. The use of a robust spring mechanism is also critical, as it must be capable of providing sufficient force to engage the brake shoes quickly and effectively. Additionally, the circuit may include safety features such as fuses or circuit breakers to protect against overload conditions, ensuring the longevity of the components involved in the electromagnetic brake system.

In summary, the electromagnetic holding brake circuit is a vital component in motor control applications, providing a reliable means of stopping and holding the motor in place when necessary. The design and implementation of this circuit require careful consideration of the electrical and mechanical components to ensure optimal performance and safety. Circuit shown in Figure 3-121. The key component of electromagnetic holding brake is an electromagnetic brake brakes, brake solenoid which is mainly composed of two parts iron and shoe brake components. When the motor access to power, electromagnetic brake coil YB also was electric pull, forcing the brake lever is moved upward, from leaving the wheel brake and release the brake shoes on the brake, the motor running. When the motor power supply is cut off (press the stop button SB2) when, YB also missing, and released under the action of the brake shoes so that the spring force of the rapid wheel brake, the motor quickly stopped.

The electromagnetic holding brake circuit operates through a solenoid mechanism that integrates seamlessly with the motor control system. The solenoid, designated as YB, serves as the primary actuator that controls the engagement and disengagement of the brake system. When the motor receives power, the solenoid coil is energized, creating a magnetic field that pulls the armature connected to the brake lever. This action lifts the brake lever, thereby retracting the brake shoes away from the wheel, allowing the motor to run freely.

The system is designed to ensure safety and efficiency. The brake shoes are held in a disengaged position during normal operation, but upon de-energizing the solenoid—typically initiated by the pressing of the stop button (SB2)—the magnetic field collapses. This results in the immediate release of the solenoid's hold on the brake lever, allowing the brake shoes to be forced back into contact with the wheel by a spring mechanism. This rapid engagement of the brake shoes effectively stops the motor, preventing any unintended motion and ensuring a controlled halt.

To enhance the reliability of the system, components such as the solenoid must be rated for the specific voltage and current requirements of the motor. The use of a robust spring mechanism is also critical, as it must be capable of providing sufficient force to engage the brake shoes quickly and effectively. Additionally, the circuit may include safety features such as fuses or circuit breakers to protect against overload conditions, ensuring the longevity of the components involved in the electromagnetic brake system.

In summary, the electromagnetic holding brake circuit is a vital component in motor control applications, providing a reliable means of stopping and holding the motor in place when necessary. The design and implementation of this circuit require careful consideration of the electrical and mechanical components to ensure optimal performance and safety. Circuit shown in Figure 3-121. The key component of electromagnetic holding brake is an electromagnetic brake brakes, brake solenoid which is mainly composed of two parts iron and shoe brake components. When the motor access to power, electromagnetic brake coil YB also was electric pull, forcing the brake lever is moved upward, from leaving the wheel brake and release the brake shoes on the brake, the motor running. When the motor power supply is cut off (press the stop button SB2) when, YB also missing, and released under the action of the brake shoes so that the spring force of the rapid wheel brake, the motor quickly stopped.