Bidirectional motor control using L293 driver

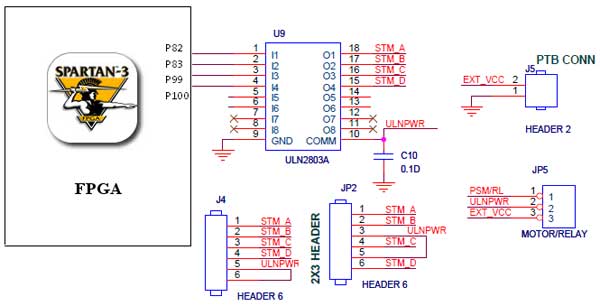

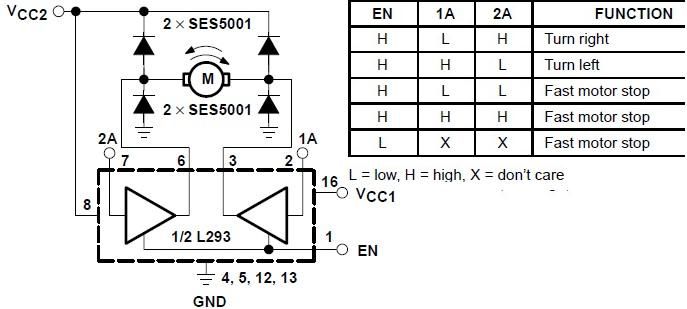

The L293 is designed to provide bidirectional drive currents of up to 1 A at voltages ranging from 4.5 V to 36 V. The L293D variant is capable of delivering bidirectional drive currents of up to 600 mA at the same voltage range. Each output features a complete totem-pole drive circuit, comprising a Darlington transistor sink and a pseudo-Darlington source. The drivers are enabled in pairs, with drivers 1 and 2 activated by the 1, 2EN input, and drivers 3 and 4 activated by the 3, 4EN input. When the enable input is high, the associated drivers are active, and their outputs are in phase with their inputs. Conversely, when the enable input is low, the drivers are disabled, and their outputs enter a high-impedance state. With the correct data inputs, each driver pair forms a full-H (or bridge) reversible drive, making it suitable for solenoid or motor applications. In a bidirectional stepper motor controller electronic project, VCC1 serves as the logic supply and must be between 4.5 and 7 volts (typically 5 volts), while VCC2 is the power supply for the motor, which must range from VCC1 up to 36 volts.

The L293 and L293D are integrated circuits commonly utilized in applications requiring motor control, particularly in robotics and automation systems. These devices facilitate the control of DC motors and stepper motors by allowing bidirectional operation, which is essential for applications where precise movement is required.

The internal structure of the L293 includes two H-bridge configurations, enabling control over the direction and speed of the motor. Each H-bridge consists of four switches that can be activated in different combinations to achieve the desired motor operation. The use of Darlington transistors in the output stage allows for high current gain and improved efficiency, making the L293 suitable for driving larger loads.

When implementing the L293 in a circuit, it is crucial to ensure proper voltage levels for VCC1 and VCC2. VCC1, the logic supply, powers the internal logic circuitry of the L293, while VCC2 provides the necessary power for the motor. It is advisable to use decoupling capacitors close to the power supply pins to filter out noise and ensure stable operation.

The enable pins (1, 2EN and 3, 4EN) play a critical role in determining the operation state of the drivers. By controlling these pins, users can effectively switch the motor on and off as needed, allowing for flexible control schemes. The high-impedance state of the outputs when disabled prevents any unwanted current flow, protecting both the drivers and the motor.

In summary, the L293 and L293D are versatile motor driver ICs that provide essential functionality for controlling motors in various applications. Their ability to handle bidirectional drive currents, coupled with the internal H-bridge configuration, makes them an ideal choice for projects requiring precise motor control.The L293 is designed to provide bidirectional drive currents of up to 1 A at voltages from 4. 5 V to 36 V. The L293D is designed to provide bidirectional drive currents of up to 600-mA at voltages from 4. 5 V to 36 V. Each output is a complete totem-pole drive circuit, with a Darlington transistor sink and a pseudo-Darlington source. Drivers are ena bled in pairs, with drivers 1 and 2 enabled by 1, 2EN and drivers 3 and 4 enabled by 3, 4EN. When an enable input is high, the associated drivers are enabled and their outputs are active and in phase with their inputs. When the enable input is low, those drivers are disabled and their outputs are off and in the high-impedance state.

With the proper data inputs, each pair of drivers forms a full-H (or bridge) reversible drive suitable for solenoid or motor applications. In this bidirectional stepper motor controller electronic project VCC1 is logic supply and must me between 4.

5 and 7 volts ( typically 5 volt) and VCC2 is the power supply for the motor and must be from VCC1 up to 36 volts 🔗 External reference

The L293 and L293D are integrated circuits commonly utilized in applications requiring motor control, particularly in robotics and automation systems. These devices facilitate the control of DC motors and stepper motors by allowing bidirectional operation, which is essential for applications where precise movement is required.

The internal structure of the L293 includes two H-bridge configurations, enabling control over the direction and speed of the motor. Each H-bridge consists of four switches that can be activated in different combinations to achieve the desired motor operation. The use of Darlington transistors in the output stage allows for high current gain and improved efficiency, making the L293 suitable for driving larger loads.

When implementing the L293 in a circuit, it is crucial to ensure proper voltage levels for VCC1 and VCC2. VCC1, the logic supply, powers the internal logic circuitry of the L293, while VCC2 provides the necessary power for the motor. It is advisable to use decoupling capacitors close to the power supply pins to filter out noise and ensure stable operation.

The enable pins (1, 2EN and 3, 4EN) play a critical role in determining the operation state of the drivers. By controlling these pins, users can effectively switch the motor on and off as needed, allowing for flexible control schemes. The high-impedance state of the outputs when disabled prevents any unwanted current flow, protecting both the drivers and the motor.

In summary, the L293 and L293D are versatile motor driver ICs that provide essential functionality for controlling motors in various applications. Their ability to handle bidirectional drive currents, coupled with the internal H-bridge configuration, makes them an ideal choice for projects requiring precise motor control.The L293 is designed to provide bidirectional drive currents of up to 1 A at voltages from 4. 5 V to 36 V. The L293D is designed to provide bidirectional drive currents of up to 600-mA at voltages from 4. 5 V to 36 V. Each output is a complete totem-pole drive circuit, with a Darlington transistor sink and a pseudo-Darlington source. Drivers are ena bled in pairs, with drivers 1 and 2 enabled by 1, 2EN and drivers 3 and 4 enabled by 3, 4EN. When an enable input is high, the associated drivers are enabled and their outputs are active and in phase with their inputs. When the enable input is low, those drivers are disabled and their outputs are off and in the high-impedance state.

With the proper data inputs, each pair of drivers forms a full-H (or bridge) reversible drive suitable for solenoid or motor applications. In this bidirectional stepper motor controller electronic project VCC1 is logic supply and must me between 4.

5 and 7 volts ( typically 5 volt) and VCC2 is the power supply for the motor and must be from VCC1 up to 36 volts 🔗 External reference