Build A Digital Tachometer/RPM Counter Circuit

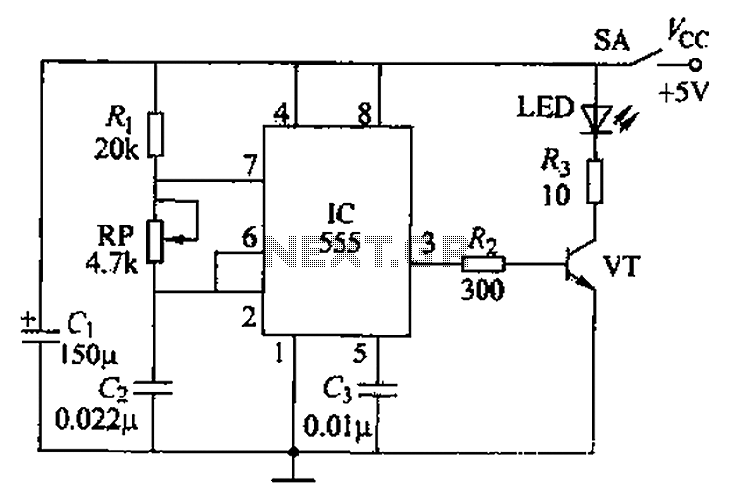

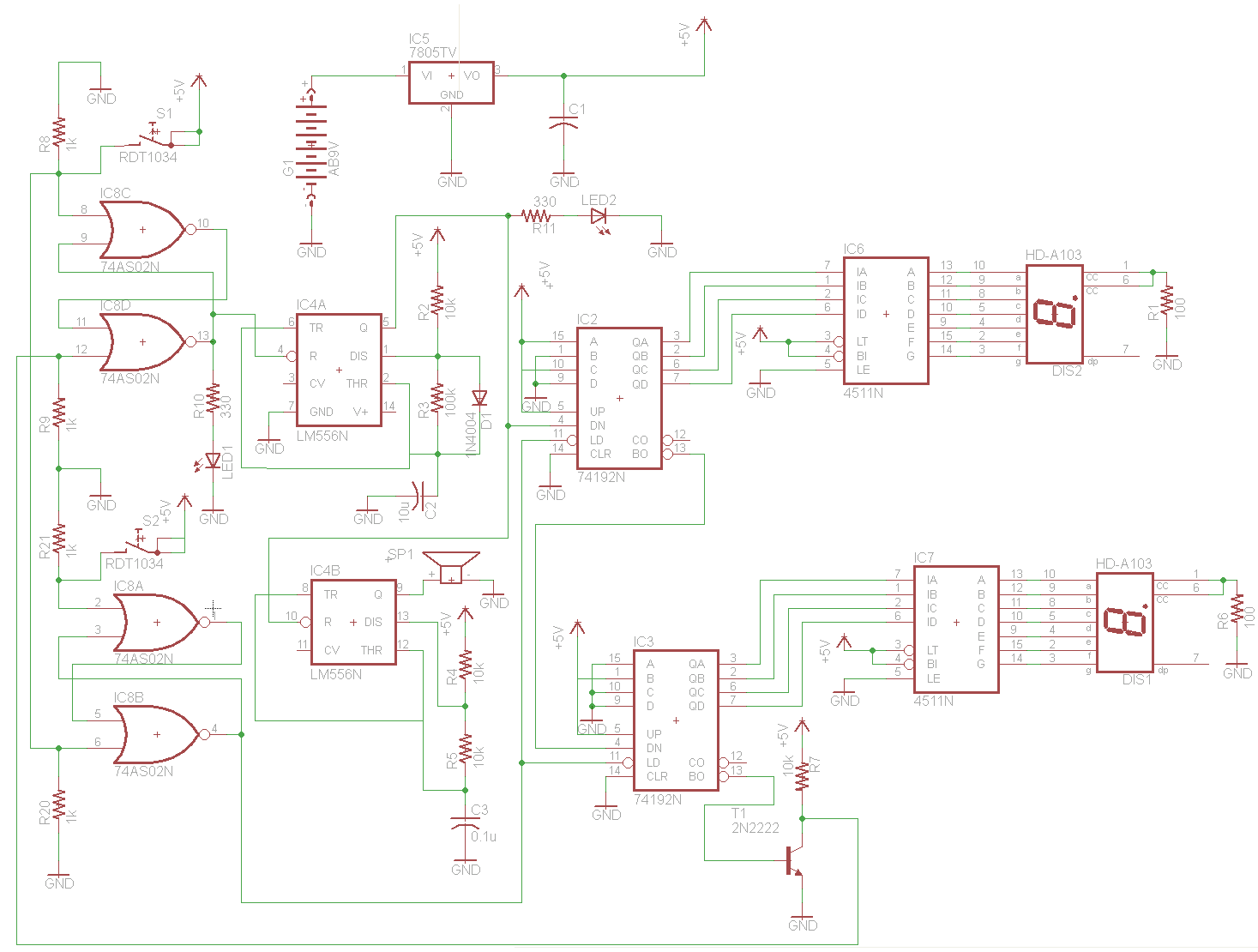

The circuit for the Digital Tachometer/RPM Counter consists of a few components. They should be connected according to the provided circuit diagram. The PIC used is on a demonstration board, meaning the clock, power, and ground pins are already connected, so these details are not included in the schematic. This circuit sends +5V pulses to the RC2/CCP1 pin of the PIC, which hosts the capture module #1 of the CCP. The standard 16x2 character LCD is utilized, interfacing through 8 bits of data and 3 control signals. The final signals to connect are power, ground, and contrast. The PIC communicates with the 16x2 LCD through the control and data lines, and the LCD responds accordingly. The HD44780 system used by this LCD is standardized, with a widely available datasheet.

The Digital Tachometer/RPM Counter circuit is designed to measure the rotational speed of a shaft or wheel and display the results on a standard 16x2 character LCD. The core of this circuit is a microcontroller, specifically a PIC microcontroller, which processes the input signals and manages the output to the LCD.

The circuit operates by generating +5V pulses that are sent to the RC2/CCP1 pin of the PIC, where the capture module #1 is located. These pulses correspond to the number of rotations per minute (RPM) of the monitored object. The PIC is programmed to count these pulses over a specific time interval, allowing it to calculate the RPM based on the frequency of the incoming pulses.

The LCD interfacing consists of an 8-bit data bus along with 3 control signals: Register Select (RS), Read/Write (R/W), and Enable (E). The PIC sends commands and data to the LCD through these lines, controlling what is displayed. The power, ground, and contrast adjustments are crucial for proper LCD operation, ensuring that the display is clear and readable.

The HD44780 controller is prevalent in many LCD applications and is well-documented, making it easier to implement and troubleshoot. The datasheet provides detailed information on the command set, timing diagrams, and electrical characteristics, enabling efficient integration into the tachometer circuit. This design allows for real-time monitoring of RPM, making it a valuable tool for various engineering applications.The circuit for the Digital Tachometer/RPM Counter tutorial consists of only a few devices. Wire them up according to the following circuit diagram. The PIC I`m using is on a demonstration board, which means the clock, power and ground pins are already wired up so I didn`t bother to include that on the schematic. This is the digital tachometer po rtion of circuit that will send +5v pulses to the RC2/CCP1 pin of the pic. The CCP module, specifically the capture module #1 on the PIC is located at this pin. This is the standard 16x2 character LCD and the interface consists of 8 bits of data, with 3 control signals. Power, Ground and Contrast are the last signals to wire up. The PIC sends commands to this 16x2 LCD over the control and data lines and the LCD does what it is told.

The HD44780 system that this LCD uses is standarized and the datasheet is widely available. 🔗 External reference

The Digital Tachometer/RPM Counter circuit is designed to measure the rotational speed of a shaft or wheel and display the results on a standard 16x2 character LCD. The core of this circuit is a microcontroller, specifically a PIC microcontroller, which processes the input signals and manages the output to the LCD.

The circuit operates by generating +5V pulses that are sent to the RC2/CCP1 pin of the PIC, where the capture module #1 is located. These pulses correspond to the number of rotations per minute (RPM) of the monitored object. The PIC is programmed to count these pulses over a specific time interval, allowing it to calculate the RPM based on the frequency of the incoming pulses.

The LCD interfacing consists of an 8-bit data bus along with 3 control signals: Register Select (RS), Read/Write (R/W), and Enable (E). The PIC sends commands and data to the LCD through these lines, controlling what is displayed. The power, ground, and contrast adjustments are crucial for proper LCD operation, ensuring that the display is clear and readable.

The HD44780 controller is prevalent in many LCD applications and is well-documented, making it easier to implement and troubleshoot. The datasheet provides detailed information on the command set, timing diagrams, and electrical characteristics, enabling efficient integration into the tachometer circuit. This design allows for real-time monitoring of RPM, making it a valuable tool for various engineering applications.The circuit for the Digital Tachometer/RPM Counter tutorial consists of only a few devices. Wire them up according to the following circuit diagram. The PIC I`m using is on a demonstration board, which means the clock, power and ground pins are already wired up so I didn`t bother to include that on the schematic. This is the digital tachometer po rtion of circuit that will send +5v pulses to the RC2/CCP1 pin of the pic. The CCP module, specifically the capture module #1 on the PIC is located at this pin. This is the standard 16x2 character LCD and the interface consists of 8 bits of data, with 3 control signals. Power, Ground and Contrast are the last signals to wire up. The PIC sends commands to this 16x2 LCD over the control and data lines and the LCD does what it is told.

The HD44780 system that this LCD uses is standarized and the datasheet is widely available. 🔗 External reference