Charge the battery capacity tester and realize the scheme

Battery capacity is a crucial indicator of battery quality. There are various methods for testing the volume of rechargeable batteries. One approach involves analyzing the discharge curve of the battery through short-term discharge tests, which can provide a rough estimate of battery capacity. This method's primary advantage is its speed; however, the discharge curve lacks universality. Many inferior batteries exhibit a steady initial voltage but experience rapid voltage drops during the middle and later stages of discharge, making this method less accurate. The most reliable and accurate method involves discharging the battery with a standard current and measuring the actual discharge time throughout the entire process. Different discharge currents yield different amounts of energy released from the rechargeable battery, leading to discrepancies. Battery capacity is standardized and typically marked according to two main discharge rates: the 10-hour rate and the 20-hour rate. The 10-hour rate indicates that the battery can discharge at a constant current for approximately 10 hours until the energy is depleted, without allowing the voltage to drop to zero at the end of discharge. Excessive discharge can reduce battery capacity, causing irreversible damage and premature failure. Each type of battery has strict regulations regarding final discharge voltage, which can be referenced in relevant data. The primary reasons rechargeable batteries fail to reach their service life include excessive discharge and overcharging. Although real-time discharge measurement methods are time-consuming and labor-intensive, they provide high accuracy that can be influenced by external factors. For a measurement process using the 10-hour discharge rate, the discharge time should last at least five hours, requiring significant patience, energy, and time. With rapid advancements in technology, microcontrollers have become widely available today. Automated control of discharge time through microcontroller programming allows for accurate measurement of battery capacity and enables full process automation. Although simulation discharge methods can waste energy, they remain feasible for small-capacity rechargeable batteries under 1A or 2A, and sampling inspections of high-capacity batteries are essential. The battery capacity tester is mechanically controlled while counting through the discharging circuit, consisting of two independent sectors. The microcontroller, which can be easily sourced from the market, is responsible for timing the discharge process and collecting reliable data for battery characteristic testing. The core of this discharging circuit is a simulation silicon-controlled rectifier. When the battery is connected to the circuit at the designated position and the activation key is pressed, the testing process begins.

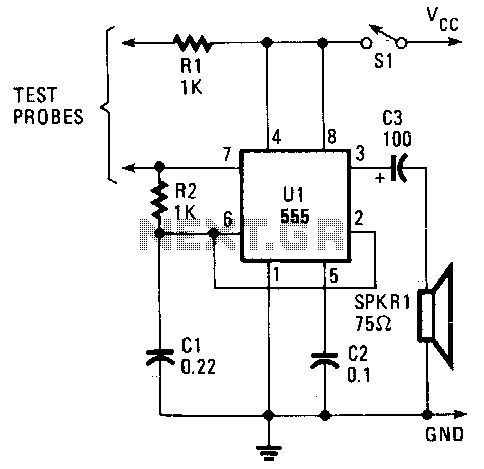

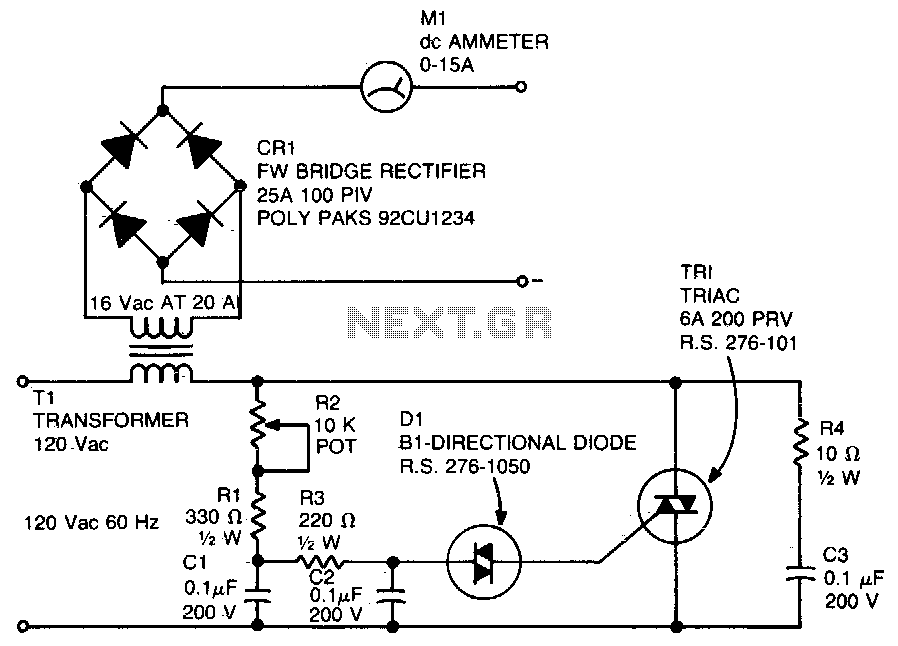

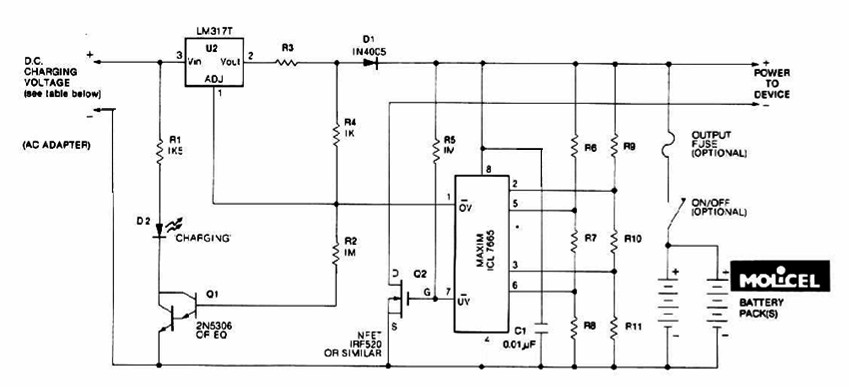

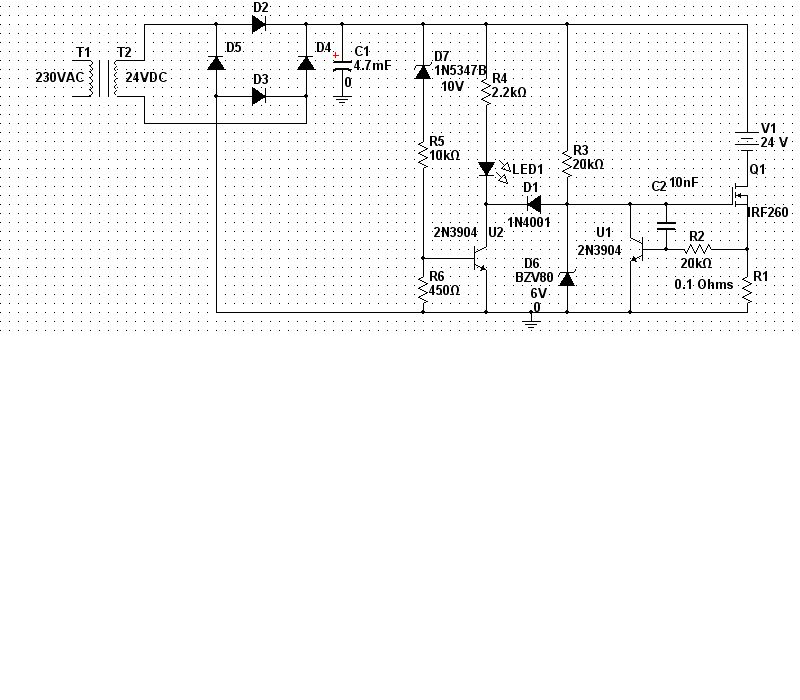

The design of a battery testing circuit should prioritize accuracy and reliability in measuring battery capacity. The circuit typically consists of several key components: a microcontroller (such as an ATmega or PIC), a silicon-controlled rectifier (SCR) for controlling the discharge, resistors for current limiting, and a voltage divider for monitoring the battery voltage during discharge.

The microcontroller can be programmed to initiate the discharge process by activating the SCR, allowing current to flow through the battery while monitoring the voltage at regular intervals. This data can then be logged for analysis, providing insights into the battery's performance characteristics, such as capacity, discharge rate, and efficiency.

For the discharge method, the circuit should be designed to accommodate different discharge rates based on the battery specifications. By implementing a variable resistor or a digital potentiometer, the discharge current can be adjusted to match the 10-hour or 20-hour rate as required.

Additionally, safety features must be integrated into the design to prevent over-discharge. This can be achieved by programming the microcontroller to monitor the voltage and automatically disconnect the load when the voltage drops below a predefined threshold, thereby protecting the battery from damage.

In conclusion, the battery testing circuit should be designed with careful consideration of component selection, programming for accuracy, and safety measures to ensure reliable and efficient battery capacity testing. This comprehensive approach will enhance the effectiveness of the testing process and extend the lifespan of rechargeable batteries.The battery capacity is the important index of weighing battery quality. There are many methods in the volume test of the rechargeable battery. Can be according to the discharge curve of the battery, carry on short time and discharge, thus so rough as to the battery capacity happen. The advantage of this kind of method maximum is fast, but the dis charge curve of the rechargeable battery does not have universality, the initial voltage is very steady too that a lot of inferior batteries discharge, once enter middle and later periods, the voltage drops very fast, so it will not very accurate to adopt the conclusion that this kind of method draws. The most reliable and most accurate one is to discharge with the standard electric current, measure the way of actual discharge time in the whole journey.

Different discharge current, the electric quantity that the rechargeable battery can be released finally is different, there is certain disparity. The capacity of the storage battery is marked unifiedly and canonial. That use most is two kinds the discharge capacity of 10 hourly rate and discharge capacity of 20 hourly rate at present.

Hourly rate discharge capacity 10 is that the battery discharge with the constant current, can keep to exhaust discharge time for about 10 hours to the electric quantity, this electric current is called 10 hourly rate electric current weigh the standard that the electric quantity uses up, it can`t be subject to that the voltage at discharge end of the battery is reduced to zero. The battery excessively discharges, will lead to the fact the battery capacity is reduced, unable to resume, and even the damage, total failure ahead of time.

So each kind of battery discharges the final voltage has a rigorous regulation, this can consult the related data. It is to cause the rechargeable battery not to reach service life, major cause to scrap to excessively discharge and excessively charge ahead of time.

Even if the shortcoming of maximum of measurement method discharging in real time is time-consuming and strenuous, because it is time consuming and long like this survey accuracy is very easy to be influenced by various external factors. Should be in above 5 hours at least if lasts discharge time in the measurement process with 10 hourly rate electric current, it needs sufficient patience, energy and abundant time even more to do so long-time test.

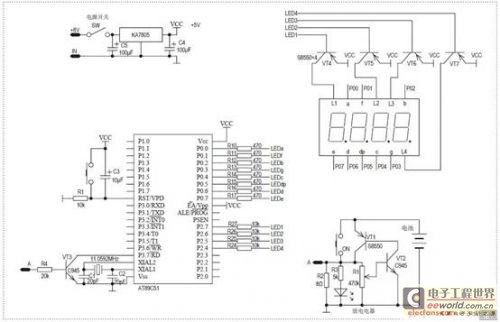

The development of science and technology is very fast, the one-chip computer has already been popularized very much today. Discharge time, carry on automation control deeply through the program control of the one-chip computer correctly, very apt perfect actual capacity of measuring the battery, realize the automatic control of the whole course.

Simulation discharges actually the method to measure capacity though a little wastes the energy, but still totally feasible to the small capacity rechargeable battery under 1A, 2A, it is very necessary too to carry on sampling inspection to the high-capacity battery. Tester of this battery capacity is mechanically controlled while counting by the discharging circuit, one piece two complete independent sectors were made up.

The part of the one-chip computer was produced time-consumingly and strenuously, and one-chip computers have been already very popular on the market, it is unnecessary to produce personally, it is all right to look for 51 one-chip computer breadboards of film at will. The discharging circuit is simpler, are only formed by four or five components. The part of the one-chip computer is mainly responsible for timing to discharge time, gets a series of reliable data finally, used in the doing in the test amount of the battery characteristic.

The essence of this kind of discharging circuit is a simulation silicon controlled rectifier. When examine the battery place in circuit in the relevant positioning, will press the activate key as us, if the batte 🔗 External reference

The design of a battery testing circuit should prioritize accuracy and reliability in measuring battery capacity. The circuit typically consists of several key components: a microcontroller (such as an ATmega or PIC), a silicon-controlled rectifier (SCR) for controlling the discharge, resistors for current limiting, and a voltage divider for monitoring the battery voltage during discharge.

The microcontroller can be programmed to initiate the discharge process by activating the SCR, allowing current to flow through the battery while monitoring the voltage at regular intervals. This data can then be logged for analysis, providing insights into the battery's performance characteristics, such as capacity, discharge rate, and efficiency.

For the discharge method, the circuit should be designed to accommodate different discharge rates based on the battery specifications. By implementing a variable resistor or a digital potentiometer, the discharge current can be adjusted to match the 10-hour or 20-hour rate as required.

Additionally, safety features must be integrated into the design to prevent over-discharge. This can be achieved by programming the microcontroller to monitor the voltage and automatically disconnect the load when the voltage drops below a predefined threshold, thereby protecting the battery from damage.

In conclusion, the battery testing circuit should be designed with careful consideration of component selection, programming for accuracy, and safety measures to ensure reliable and efficient battery capacity testing. This comprehensive approach will enhance the effectiveness of the testing process and extend the lifespan of rechargeable batteries.The battery capacity is the important index of weighing battery quality. There are many methods in the volume test of the rechargeable battery. Can be according to the discharge curve of the battery, carry on short time and discharge, thus so rough as to the battery capacity happen. The advantage of this kind of method maximum is fast, but the dis charge curve of the rechargeable battery does not have universality, the initial voltage is very steady too that a lot of inferior batteries discharge, once enter middle and later periods, the voltage drops very fast, so it will not very accurate to adopt the conclusion that this kind of method draws. The most reliable and most accurate one is to discharge with the standard electric current, measure the way of actual discharge time in the whole journey.

Different discharge current, the electric quantity that the rechargeable battery can be released finally is different, there is certain disparity. The capacity of the storage battery is marked unifiedly and canonial. That use most is two kinds the discharge capacity of 10 hourly rate and discharge capacity of 20 hourly rate at present.

Hourly rate discharge capacity 10 is that the battery discharge with the constant current, can keep to exhaust discharge time for about 10 hours to the electric quantity, this electric current is called 10 hourly rate electric current weigh the standard that the electric quantity uses up, it can`t be subject to that the voltage at discharge end of the battery is reduced to zero. The battery excessively discharges, will lead to the fact the battery capacity is reduced, unable to resume, and even the damage, total failure ahead of time.

So each kind of battery discharges the final voltage has a rigorous regulation, this can consult the related data. It is to cause the rechargeable battery not to reach service life, major cause to scrap to excessively discharge and excessively charge ahead of time.

Even if the shortcoming of maximum of measurement method discharging in real time is time-consuming and strenuous, because it is time consuming and long like this survey accuracy is very easy to be influenced by various external factors. Should be in above 5 hours at least if lasts discharge time in the measurement process with 10 hourly rate electric current, it needs sufficient patience, energy and abundant time even more to do so long-time test.

The development of science and technology is very fast, the one-chip computer has already been popularized very much today. Discharge time, carry on automation control deeply through the program control of the one-chip computer correctly, very apt perfect actual capacity of measuring the battery, realize the automatic control of the whole course.

Simulation discharges actually the method to measure capacity though a little wastes the energy, but still totally feasible to the small capacity rechargeable battery under 1A, 2A, it is very necessary too to carry on sampling inspection to the high-capacity battery. Tester of this battery capacity is mechanically controlled while counting by the discharging circuit, one piece two complete independent sectors were made up.

The part of the one-chip computer was produced time-consumingly and strenuously, and one-chip computers have been already very popular on the market, it is unnecessary to produce personally, it is all right to look for 51 one-chip computer breadboards of film at will. The discharging circuit is simpler, are only formed by four or five components. The part of the one-chip computer is mainly responsible for timing to discharge time, gets a series of reliable data finally, used in the doing in the test amount of the battery characteristic.

The essence of this kind of discharging circuit is a simulation silicon controlled rectifier. When examine the battery place in circuit in the relevant positioning, will press the activate key as us, if the batte 🔗 External reference