Automatic Air Humidifier

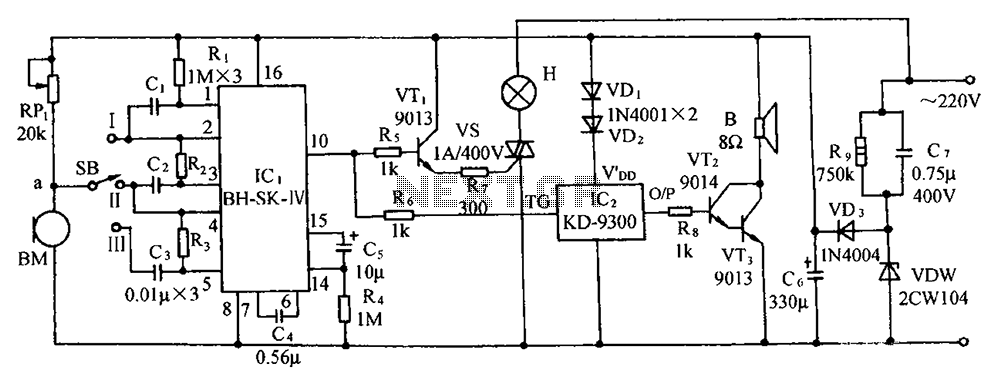

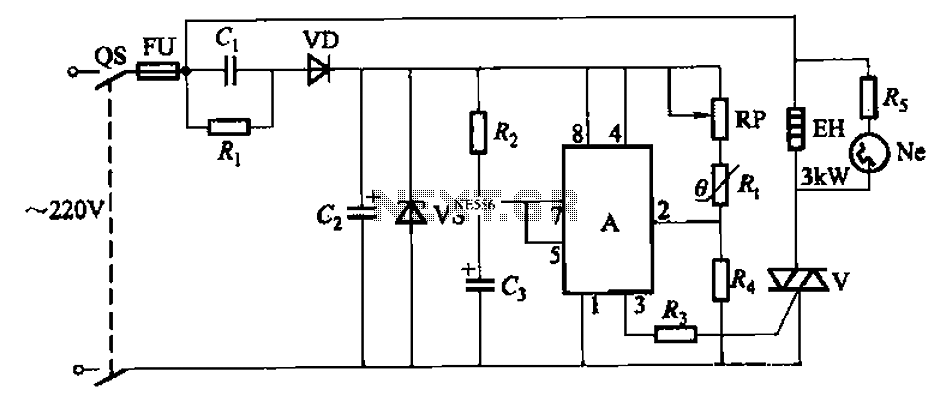

The humidifier circuit is based on a specific humidity sensor, Type NH-3 from Figaro. The circuit controls a ventilator that is part of an air humidifying system, depending on the sensor output. A triac is used to switch the ventilator on and off. To maintain simplicity, both the supply voltage and the test voltage are derived directly from the mains supply. The 240 V mains voltage is converted into an 8.9 V pulsating direct voltage using capacitor C1, resistor R1, and zener diode D1. This pulsating voltage powers the sensor and is transformed into a 7.5 V supply voltage by D2 and C2. The sensor requires an alternating drive voltage not exceeding 1.5 V, which is achieved from the pulsating direct voltage through the R2-R3-C3-C4 network that eliminates the direct voltage component and reduces the level to 1.4 V. This network also acts as a 50 Hz bandpass filter. To ensure that the drive voltage for the sensor remains within the common-mode range of op amp IC2, an offset potential of 3.9 V is applied to both the sensor and the voltage reference source of the op amp, provided by zener diode D3. The reference level is adjusted with potentiometer P1, and hysteresis is introduced by resistor R5. When the ambient humidity exceeds the level set with P1, the output voltage of IC2 reaches approximately 6 V, cutting off T1 via D4, which in turn disables the triac. Conversely, when humidity falls below the level set with P1, a pulsating voltage appears at the output of IC2, charging capacitor C6. The charged capacitor then supplies a steady current to the triac. If T1 is cut off for an extended period, capacitor C6 discharges through resistor R7. Capacitors C1 and C7 discharge through R9, ensuring that no dangerous voltage remains at the mains connector (K1) after the mains is switched off. The humidifier is ideally constructed on the PCB shown in Figure 2, which is available as a ready-made option. It is important to note that portions of the board will carry mains voltage, necessitating careful handling and enclosing the board in a plastic case. The humidifier can be converted into a dehumidifier by swapping connections 1 and 3 of sensor IC1.

The humidifier circuit utilizes a humidity sensor (Type NH-3) to monitor environmental moisture levels and control a ventilator for air humidification. The system is powered by the mains supply, which is transformed into lower DC voltages suitable for sensor operation. The circuit includes essential components such as capacitors, resistors, zener diodes, and a triac, all working together to create a reliable and efficient humidification mechanism.

The conversion of 240 V AC to 8.9 V pulsating DC is critical for powering the sensor and supporting the circuit's functionality. The design incorporates a bandpass filter to ensure that the sensor receives a stable alternating voltage, which is essential for accurate humidity detection. The op amp (IC2) plays a crucial role in processing the sensor's output, providing a control signal that regulates the triac, thus controlling the ventilator's operation based on humidity levels.

The feedback mechanism through hysteresis ensures that the system operates effectively without rapid on-off cycling, enhancing the overall stability of the humidification process. The inclusion of discharge paths for capacitors after power-off is a safety feature, preventing any residual voltage that could pose a hazard during maintenance or operation.

Overall, this circuit design exemplifies a practical approach to humidity control in an air humidifying system, with considerations for safety, component selection, and operational efficiency.The humidifier circuit is based on a special humidity sensor Type NH-3 from Figaro. Depending on the sensor output, the circuit drives a ventilator that is part of an air humidifying installation. The ventilator is switched on an off by a triac. So as to keep the circuit as simple as possible, the supply voltage and the test voltage are drawn dire

ctly from the mains supply. The 240 V mains voltage is converted into an 8. 9 V pulsating direct potential by capacitor C1, resistor R1 and zener diode D1. The pulsating voltage is used to drive the sensor. It is also transformed to a 7. 5 V supply voltage by D2 and C2. The sensor needs an alternating drive voltage at a level not higher than 1. 5 V. This potential is obtained from the pulsating direct voltage by network R2-R3-C3-C4, which removes the direct voltage component and lowers the level to 1. 4 V. At the same time, the network functions as a 50 Hz bandpass filter. To ensure that the drive voltage for the sensor does not fall outside the common-mode range of op amp IC2, an offset potential of 3.

9 V is applied to the sensor as well as to the voltage reference source of the op amp. This potential is provided by zener diode D3. The reference level is set with P1. The op amp is given some hysteresis by R5. When the humidity of the ambient air rises above that corresponding to the level with P1, the output voltage of IC2 is about 6 V. This results in T1 being cut off by D4, whereupon the triac is also disabled. When the humidity drops below that corresponding to the level set with P1, a pulsating potential appears at the output of IC2.

This voltage is used to charge capacitor C6. The charged capacitor thereupon provides a steady current to the triac. When T1 is cut off for some time, capacitor C6 is discharged via resistor R7. Capacitors C1 and C7 are discharged via R9, so that after the mains has been switched off, no dangerous potential remains at the pins of the mains connector (K1). The humidifier is best built on the PCB shown in Figure 2, which is available ready made (see Readers services pages towards the end of this issue).

Bear in mind that parts of the board will carry mains voltage, which makes careful working and the enclosing of the board in a plastic case imperative. The humidifier may be converted into a dehumidifier by interchanging connections 1 and 3 to sensor IC1.

🔗 External reference

The humidifier circuit utilizes a humidity sensor (Type NH-3) to monitor environmental moisture levels and control a ventilator for air humidification. The system is powered by the mains supply, which is transformed into lower DC voltages suitable for sensor operation. The circuit includes essential components such as capacitors, resistors, zener diodes, and a triac, all working together to create a reliable and efficient humidification mechanism.

The conversion of 240 V AC to 8.9 V pulsating DC is critical for powering the sensor and supporting the circuit's functionality. The design incorporates a bandpass filter to ensure that the sensor receives a stable alternating voltage, which is essential for accurate humidity detection. The op amp (IC2) plays a crucial role in processing the sensor's output, providing a control signal that regulates the triac, thus controlling the ventilator's operation based on humidity levels.

The feedback mechanism through hysteresis ensures that the system operates effectively without rapid on-off cycling, enhancing the overall stability of the humidification process. The inclusion of discharge paths for capacitors after power-off is a safety feature, preventing any residual voltage that could pose a hazard during maintenance or operation.

Overall, this circuit design exemplifies a practical approach to humidity control in an air humidifying system, with considerations for safety, component selection, and operational efficiency.The humidifier circuit is based on a special humidity sensor Type NH-3 from Figaro. Depending on the sensor output, the circuit drives a ventilator that is part of an air humidifying installation. The ventilator is switched on an off by a triac. So as to keep the circuit as simple as possible, the supply voltage and the test voltage are drawn dire

ctly from the mains supply. The 240 V mains voltage is converted into an 8. 9 V pulsating direct potential by capacitor C1, resistor R1 and zener diode D1. The pulsating voltage is used to drive the sensor. It is also transformed to a 7. 5 V supply voltage by D2 and C2. The sensor needs an alternating drive voltage at a level not higher than 1. 5 V. This potential is obtained from the pulsating direct voltage by network R2-R3-C3-C4, which removes the direct voltage component and lowers the level to 1. 4 V. At the same time, the network functions as a 50 Hz bandpass filter. To ensure that the drive voltage for the sensor does not fall outside the common-mode range of op amp IC2, an offset potential of 3.

9 V is applied to the sensor as well as to the voltage reference source of the op amp. This potential is provided by zener diode D3. The reference level is set with P1. The op amp is given some hysteresis by R5. When the humidity of the ambient air rises above that corresponding to the level with P1, the output voltage of IC2 is about 6 V. This results in T1 being cut off by D4, whereupon the triac is also disabled. When the humidity drops below that corresponding to the level set with P1, a pulsating potential appears at the output of IC2.

This voltage is used to charge capacitor C6. The charged capacitor thereupon provides a steady current to the triac. When T1 is cut off for some time, capacitor C6 is discharged via resistor R7. Capacitors C1 and C7 are discharged via R9, so that after the mains has been switched off, no dangerous potential remains at the pins of the mains connector (K1). The humidifier is best built on the PCB shown in Figure 2, which is available ready made (see Readers services pages towards the end of this issue).

Bear in mind that parts of the board will carry mains voltage, which makes careful working and the enclosing of the board in a plastic case imperative. The humidifier may be converted into a dehumidifier by interchanging connections 1 and 3 to sensor IC1.

🔗 External reference