Motor Control Circuit of LM339

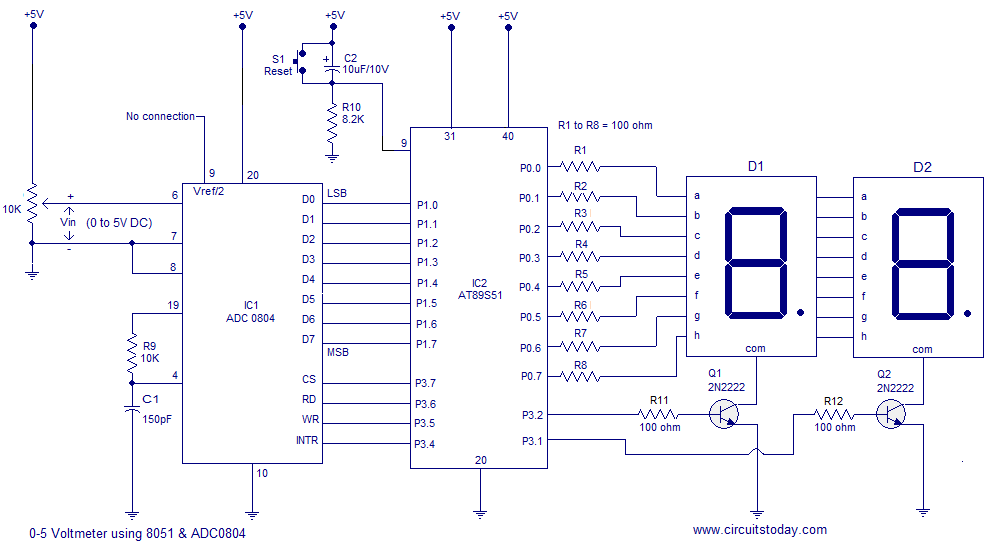

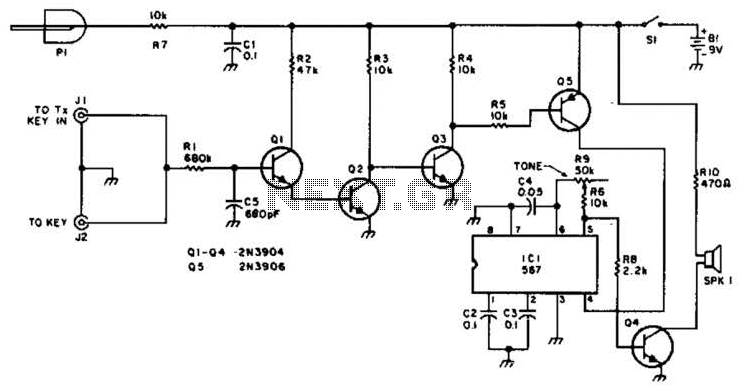

The motor control circuit depicted in the image utilizes the LM339 comparator among other components. When the input control signal is high (PWL), comparators A and A3 activate the power amplifier circuit, which consists of A4, VT5, and VT6, thereby driving the motor M. Concurrently, the comparator outputs a signal that resets the integral capacitance C1, which monitors the armature current.

The motor control circuit operates by employing the LM339, a quad comparator, to analyze the input control signal. When the signal is high, it triggers comparators A and A3, which in turn activate a power amplifier circuit formed by operational amplifier A4 and transistors VT5 and VT6. This configuration allows for efficient control of the motor M, ensuring it receives the necessary power to operate.

The inclusion of capacitance C1 serves a crucial role in the circuit by integrating the armature current, providing feedback to stabilize the motor's operation. The reset function of C1 is vital for maintaining accurate monitoring of the armature current, preventing overload conditions by ensuring that the current does not exceed safe operating limits.

The overall design emphasizes reliability and responsiveness, making it suitable for applications requiring precise motor control. The use of comparators allows for quick adjustments to the motor's power based on real-time input signals, while the feedback mechanism helps in maintaining consistent performance under varying load conditions. This circuit is ideal for automation and robotics where motor control precision is essential.The above picture is the motor control circuit composed of LM339 etc.When the input control signal is high PWL,comparator A and A3 make power amplifier conduct composed of A4,VT5 and VT6 and it drives motor M.At the same time,comparator also outputs and removes the armature current integral capacitance C1 reset.The armature current monitors the current e.. 🔗 External reference

The motor control circuit operates by employing the LM339, a quad comparator, to analyze the input control signal. When the signal is high, it triggers comparators A and A3, which in turn activate a power amplifier circuit formed by operational amplifier A4 and transistors VT5 and VT6. This configuration allows for efficient control of the motor M, ensuring it receives the necessary power to operate.

The inclusion of capacitance C1 serves a crucial role in the circuit by integrating the armature current, providing feedback to stabilize the motor's operation. The reset function of C1 is vital for maintaining accurate monitoring of the armature current, preventing overload conditions by ensuring that the current does not exceed safe operating limits.

The overall design emphasizes reliability and responsiveness, making it suitable for applications requiring precise motor control. The use of comparators allows for quick adjustments to the motor's power based on real-time input signals, while the feedback mechanism helps in maintaining consistent performance under varying load conditions. This circuit is ideal for automation and robotics where motor control precision is essential.The above picture is the motor control circuit composed of LM339 etc.When the input control signal is high PWL,comparator A and A3 make power amplifier conduct composed of A4,VT5 and VT6 and it drives motor M.At the same time,comparator also outputs and removes the armature current integral capacitance C1 reset.The armature current monitors the current e.. 🔗 External reference