Ultrasonic Sensor Circuit

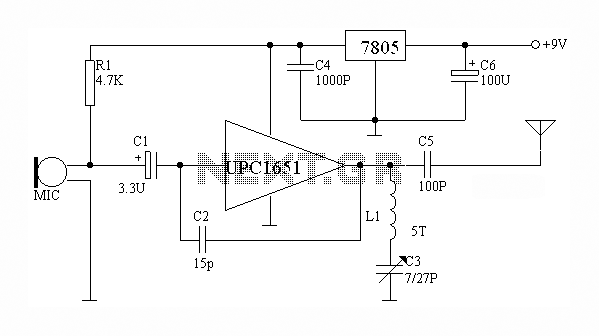

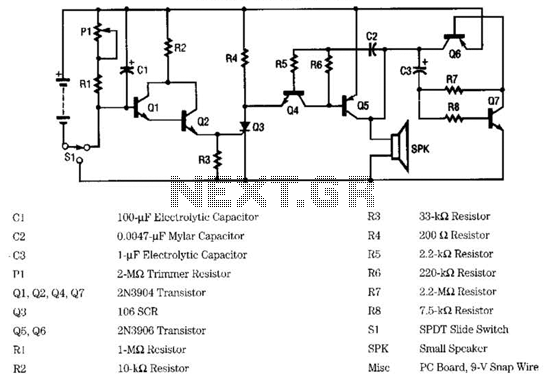

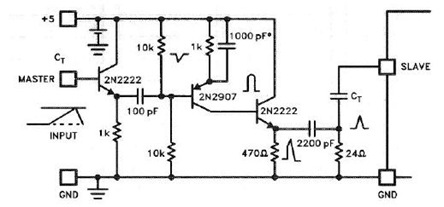

The ultrasonic sensor circuit comprises a transmitter and a receiver, which are essential for remote control applications. The circuit operates at sound frequencies above 20 kHz, typically between 40 kHz and 50 kHz, powered by a 9V battery. When the switch is activated, the transmitter sends signals that are received by the receiver circuit. Ultrasonic acoustic waves can range from 20 kHz to about 20 MHz. In this context, 's' represents distance in meters, 'v' denotes the speed of sound at 344 m/s, and 't' indicates the travel time in seconds. Most obstacles reflect ultrasound waves partially, while some absorb them, and others allow them to pass through. The ultrasonic sensor converts sound waves into electrical signals. The generation of ultrasonic waves occurs through piezoelectric materials, which produce waves at a frequency of 40 kHz when an oscillator is applied. Ultrasonic sensors are primarily utilized for non-contact measurement applications, emitting sound waves toward a target that reflects the waves back to the sensor. The system measures the time taken for the waves to return, calculating the distance to the target using the speed of sound in the medium. The ultrasonic sensor circuit includes a transmitter, receiver, and comparator. Ultrasonic waves are produced by thin piezoelectric crystals, which convert electrical energy into mechanical energy. The input voltage causes the ceramics to stretch, emitting ultrasonic waves. The transmission operates at around 32 kHz frequency from piezoelectric elements, achieving better efficiency when the oscillator frequency aligns with the piezoelectric resonance frequency. In pulse measuring mode, the same piezoelectric element can function as both transmitter and receiver. The output frequency relies on the operating frequency of the oscillator, which is adjusted for each transducer. This characteristic makes piezoelectric transducers particularly suitable for ultrasonic sensors. The transmitter generates ultrasonic waves at a frequency of 40 kHz, produced by an oscillator circuit, with the output signal amplified. The frequency components depend on the RLC or crystal oscillator design used. The signal amplifier provides electrical feedback to the piezoelectric material, enabling it to vibrate and emit the appropriate frequency. The receiver consists of ultrasonic transducers made from piezoelectric materials, capturing reflected waves from the transmitter or direct Line of Sight (LOS) waves. The piezoelectric material generates electrical voltage when waves with resonant frequency strike it, causing the ceramic element to vibrate.

The ultrasonic sensor circuit is an effective tool for measuring distances in various applications, including robotics, automotive systems, and industrial automation. The design typically includes several key components: a piezoelectric transducer, an oscillator, an amplifier, and a microcontroller or comparator for processing the signals.

The piezoelectric transducer serves dual roles in this circuit; it acts as both the transmitter and receiver of ultrasonic waves. The oscillator generates a high-frequency signal, which is fed into the piezoelectric transducer, causing it to emit ultrasonic waves. The frequency of the oscillator is critical; it must be tuned to the resonant frequency of the transducer to maximize efficiency and sensitivity.

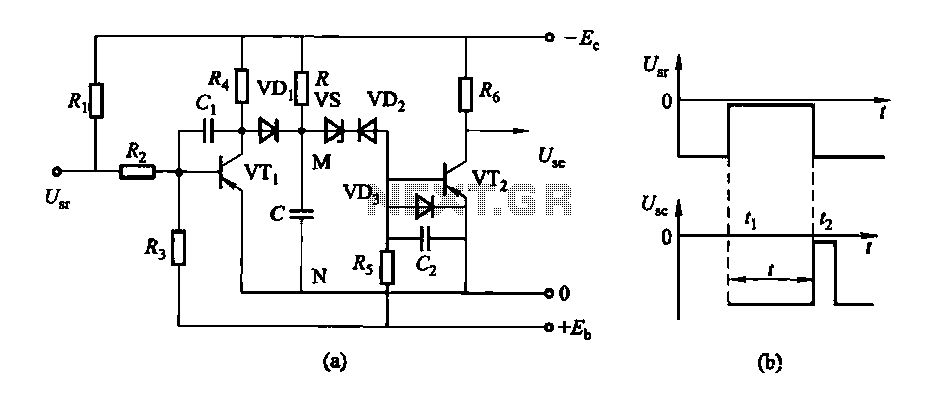

When the ultrasonic waves encounter an object, they are reflected back toward the sensor. The receiver, also a piezoelectric transducer, detects these reflected waves. The time taken for the waves to return is measured, allowing the circuit to calculate the distance to the object using the formula \( s = vt \), where \( s \) is the distance, \( v \) is the speed of sound, and \( t \) is the time of flight.

The amplifier boosts the received signal, making it easier for the microcontroller or comparator to process. The comparator can be programmed to trigger specific actions based on the measured distance, making the system adaptable for various applications, such as obstacle detection in autonomous vehicles or level sensing in tanks.

In summary, the ultrasonic sensor circuit is a sophisticated system that leverages the principles of sound wave propagation and piezoelectricity to perform accurate distance measurements. Its versatility and non-contact measurement capability make it an invaluable component in many modern electronic applications.Ultrasonic sensor circuit is a sensor that consists of transmitter and receiver. This circuit is useful for remote control. The frequency of sound produced by a series of Ultrasonic Sensor is above 20 KHz which is between 40 KHz 50 KHz. Used power supply voltage is 9 V battery cans so use with a voltage of 9 V. How it works is a series of ultr asonic sensors in the circuit if the switch is pressed then the transmitter will from send signals received by the receiver circuit. Ultrasound acoustic wave having a frequency of 20 kHz to about 20 MHz. The Following is a schematic drawing: where s is the distance in units of meters, v is the speed of sound is 344 m / s and t is the travel time in seconds.

While most obstacles ultrasound waves are reflected partly absorbed and some other people will be continued. Ultrasonic sensor is a sensor that changes the physical quantities (sound) to the amount of electricity.

In this case an ultrasonic wave sensor generated through an agency called piezoelectric. This will produce piezoelectric ultrasonic waves with a frequency of 40 kHz when an oscillator is applied to the object. Ultrasonic sensors typically used for a disclosure does not touch such a variety of measurement applications.

This tool is generally emit ultrasonic sound waves toward the target that reflects the waves back toward the sensor. The system measures the time required for the transmission of waves to go back and calculate the distance to the target sensor by using the speed of sound in the medium.

Compiler series ultrasonic sensor consists of transmitter, receiver, and comparator. In addition, ultrasonic waves generated by a thin piezoelectric crystals. Direct piezoelectric equipment change electrical energy into mechanical energy. Input voltage causes a ceramic that is used to stretch and emit ultrasonic waves. Type of transmission operations in around 32 kHz frequency piezoelectric elements. Better efficiency, if the oscillator frequency is set at the piezoelectric resonance frequency with the best sensitivity and efficiency. If the pulse measuring mode the circuit operates on the same piezoelectric element can be used as a transmitter and receiver.

The resulting frequency depends on the operating frequency of the oscillator was adjusted from each transducer. Because of this advantage is more suitable for piezoelectric transducers ultrasonic sensors. Transmitter is a device that functions as an ultrasonic wave transmitter with a frequency of 40 kHz is generated from an oscillator.

To produce frequency 40 KHz, to make the oscillator circuit and the output of the oscillator signal and hold amplifier. The number of frequency components is determined by the prop RLC / crystal oscillator, depending on the design used.

Signal amplifier will provide electrical signals in the feedback to the piezoelectric and mechanical reactions that vibrate and emit the appropriate frequency oscillator. Recipient consists of ultrasonic transducers using piezoelectric material, which serves as the recipient of reflection waves from the transmitter worn on the surface of an object or a wave of direct LOS (Line of Sight) from the transmitter.

Because the piezoelectric material has a reversible reaction, a ceramic element to generate electrical voltage when the wave came with resonant frequency and will vibrate the piezoelectric material. 🔗 External reference

The ultrasonic sensor circuit is an effective tool for measuring distances in various applications, including robotics, automotive systems, and industrial automation. The design typically includes several key components: a piezoelectric transducer, an oscillator, an amplifier, and a microcontroller or comparator for processing the signals.

The piezoelectric transducer serves dual roles in this circuit; it acts as both the transmitter and receiver of ultrasonic waves. The oscillator generates a high-frequency signal, which is fed into the piezoelectric transducer, causing it to emit ultrasonic waves. The frequency of the oscillator is critical; it must be tuned to the resonant frequency of the transducer to maximize efficiency and sensitivity.

When the ultrasonic waves encounter an object, they are reflected back toward the sensor. The receiver, also a piezoelectric transducer, detects these reflected waves. The time taken for the waves to return is measured, allowing the circuit to calculate the distance to the object using the formula \( s = vt \), where \( s \) is the distance, \( v \) is the speed of sound, and \( t \) is the time of flight.

The amplifier boosts the received signal, making it easier for the microcontroller or comparator to process. The comparator can be programmed to trigger specific actions based on the measured distance, making the system adaptable for various applications, such as obstacle detection in autonomous vehicles or level sensing in tanks.

In summary, the ultrasonic sensor circuit is a sophisticated system that leverages the principles of sound wave propagation and piezoelectricity to perform accurate distance measurements. Its versatility and non-contact measurement capability make it an invaluable component in many modern electronic applications.Ultrasonic sensor circuit is a sensor that consists of transmitter and receiver. This circuit is useful for remote control. The frequency of sound produced by a series of Ultrasonic Sensor is above 20 KHz which is between 40 KHz 50 KHz. Used power supply voltage is 9 V battery cans so use with a voltage of 9 V. How it works is a series of ultr asonic sensors in the circuit if the switch is pressed then the transmitter will from send signals received by the receiver circuit. Ultrasound acoustic wave having a frequency of 20 kHz to about 20 MHz. The Following is a schematic drawing: where s is the distance in units of meters, v is the speed of sound is 344 m / s and t is the travel time in seconds.

While most obstacles ultrasound waves are reflected partly absorbed and some other people will be continued. Ultrasonic sensor is a sensor that changes the physical quantities (sound) to the amount of electricity.

In this case an ultrasonic wave sensor generated through an agency called piezoelectric. This will produce piezoelectric ultrasonic waves with a frequency of 40 kHz when an oscillator is applied to the object. Ultrasonic sensors typically used for a disclosure does not touch such a variety of measurement applications.

This tool is generally emit ultrasonic sound waves toward the target that reflects the waves back toward the sensor. The system measures the time required for the transmission of waves to go back and calculate the distance to the target sensor by using the speed of sound in the medium.

Compiler series ultrasonic sensor consists of transmitter, receiver, and comparator. In addition, ultrasonic waves generated by a thin piezoelectric crystals. Direct piezoelectric equipment change electrical energy into mechanical energy. Input voltage causes a ceramic that is used to stretch and emit ultrasonic waves. Type of transmission operations in around 32 kHz frequency piezoelectric elements. Better efficiency, if the oscillator frequency is set at the piezoelectric resonance frequency with the best sensitivity and efficiency. If the pulse measuring mode the circuit operates on the same piezoelectric element can be used as a transmitter and receiver.

The resulting frequency depends on the operating frequency of the oscillator was adjusted from each transducer. Because of this advantage is more suitable for piezoelectric transducers ultrasonic sensors. Transmitter is a device that functions as an ultrasonic wave transmitter with a frequency of 40 kHz is generated from an oscillator.

To produce frequency 40 KHz, to make the oscillator circuit and the output of the oscillator signal and hold amplifier. The number of frequency components is determined by the prop RLC / crystal oscillator, depending on the design used.

Signal amplifier will provide electrical signals in the feedback to the piezoelectric and mechanical reactions that vibrate and emit the appropriate frequency oscillator. Recipient consists of ultrasonic transducers using piezoelectric material, which serves as the recipient of reflection waves from the transmitter worn on the surface of an object or a wave of direct LOS (Line of Sight) from the transmitter.

Because the piezoelectric material has a reversible reaction, a ceramic element to generate electrical voltage when the wave came with resonant frequency and will vibrate the piezoelectric material. 🔗 External reference