Controlling stepper motors

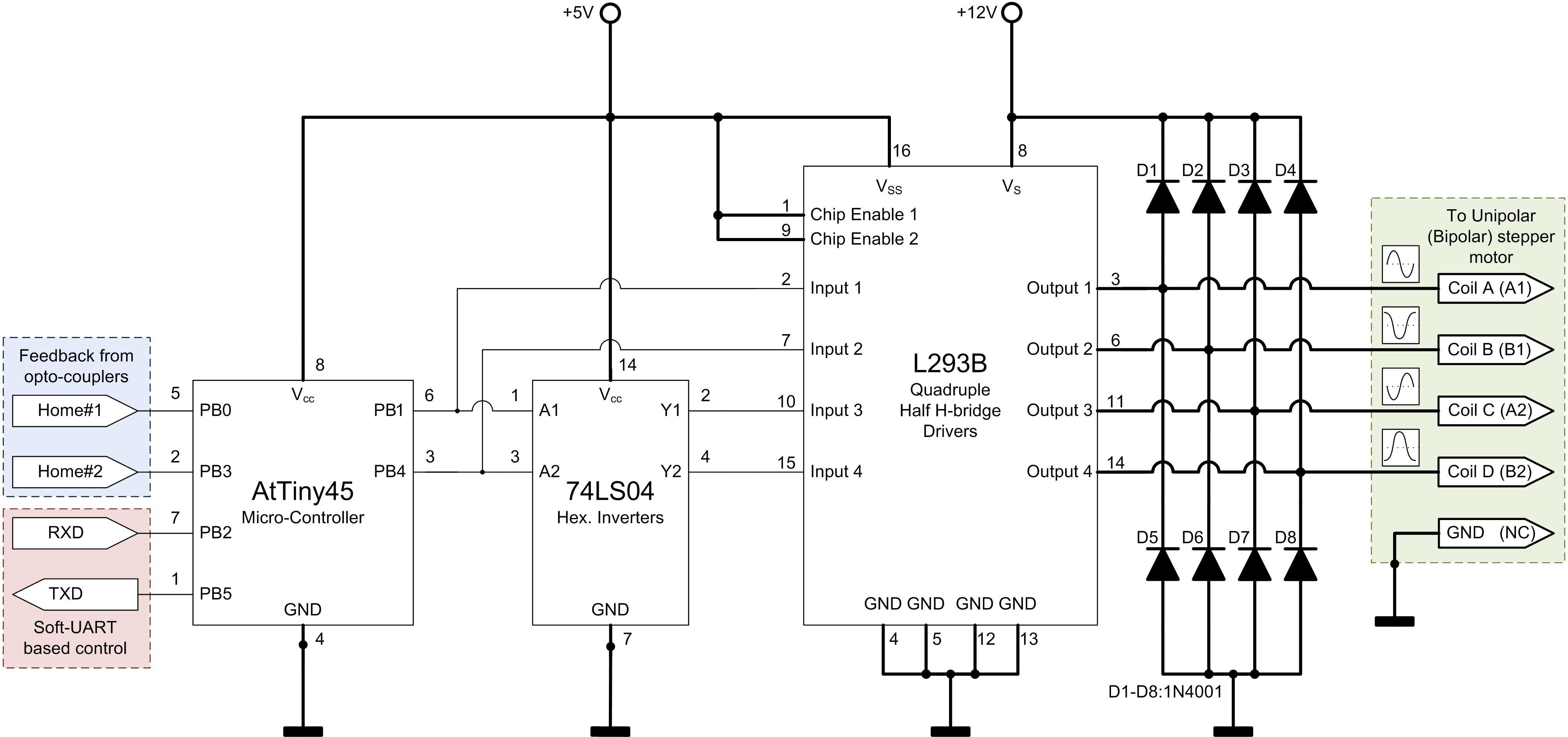

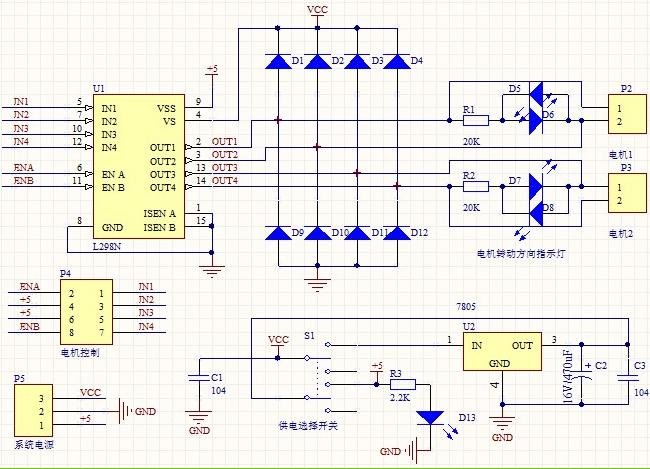

The first pulse motor that is used to position control. Features were incorporated for positioning control. This does not mean intelligent and autonomous driving the motor in response to movement commands from the host. The key to controlling the pulse motor is to prevent slowly varying speed during starting and stopping, which became a highlight of this feature. The parameters required for control (such as maximum speed, acceleration, excitation system) can be changed via commands. The host controller sends commands through an RS232C connection, with no protocol to control communication software easily. The following details each command:

- Absolute move: M <n> - Go to <n> location, possible values are 0 to 32767.

- Relative movement: + <n>, - <n> - From the current position +/- <n> step moves, possible values are 0 to 65536.

- Homing: R <n> - Set the location counter value to return to the origin at a constant rate of 200pps, reverse feed input until detection, then finish until the origin input. Usually, omit the (0).

- Set location counter: P <n> - Set the location counter value, 0 is equivalent to setting the value omitted.

- Set velocity: V <n> - Set the moving speed, range from 0 to 31, corresponding to 166pps ~ 1266pps unit at 33pps.

- Acceleration setting: A <n> - Set acceleration at starting and stopping, range from 0 to 15, higher values indicate gradual acceleration and deceleration.

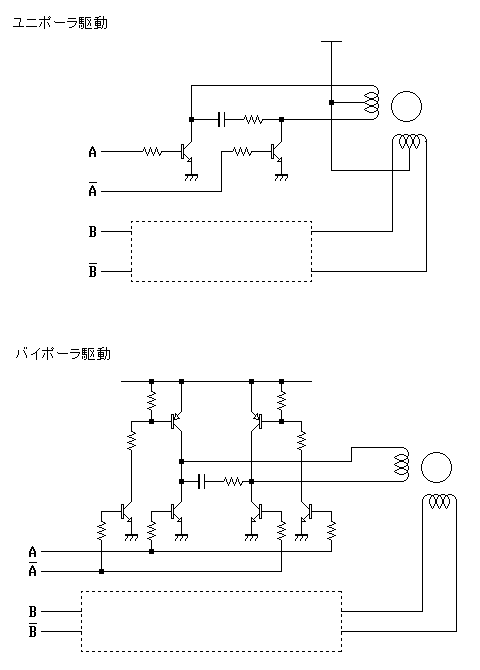

- Excitation system settings: M <n> - Set the mode of excitation pulse motor, value between 0 and 3.

- Excitation ON/OFF: D <n> - Excitation of the motor output ON/OFF, 0 OFF (default), 1 ON. The OFF command disables pulse excitation mode.

- Step movement: "<", ">" - Run command immediately upon receiving the letter, "<" for step backward, ">" for advance in 1 step.

- Parameters read: "?" - Read P-value, V value, A value, M value.

- Store operating parameters: "_" - Store values V, A, M in EEPROM for next startup.

- Sudden stop - Break during move command signal transfer (20ms or more) for immediate stop.

- Return value - After the process, returns the result code for each command.

The pulse motor system described relies on precise control mechanisms to ensure accurate positioning and movement. The motor operates under a set of commands that dictate its behavior, allowing for both absolute and relative movements. The absolute move command (M <n>) directs the motor to a specific position within a defined range, while relative movements (+ <n> or - <n>) adjust the motor's current position incrementally.

The homing command (R <n>) is crucial for establishing a reference point for the motor's movements, ensuring that the system can return to a known state. The speed of the motor can be adjusted through the velocity command (V <n>), which allows for fine-tuning of performance based on application requirements. This is complemented by the acceleration setting (A <n>), which controls how quickly the motor can start and stop, thus enhancing operational efficiency.

The excitation system settings (M <n>) and excitation ON/OFF commands (D <n>) provide flexibility in how the motor is powered, allowing for different operational modes depending on the task at hand. Step movement commands ("<" and ">") enable immediate response to control inputs, providing real-time adjustments to the motor's position.

The ability to read parameters with the "?" command and store operating parameters in EEPROM ensures that the system retains its settings across power cycles, enhancing reliability and ease of use. The sudden stop feature allows for immediate cessation of motor activity, which is critical for safety in dynamic environments.

Overall, this pulse motor system is designed for precision control in various applications, leveraging a robust command set to enable flexible operation and efficient performance.The first pulse motor that is used to diss it because it is the positioning control things, we decided to incorporate features that may be needed for positioning control. This does not mean that intelligent, and autonomous driving the motor in response to movement commands from the host.

The key to controlling the pulse motor, the stall is to prevent slowly varying speed during starting and stopping, and of course also be applied to control and became a highlight of this feature. The parameters required for control (such as maximum speed, acceleration, excitation system) to be able to change the command.

And the host controller sends commands to the RS232C connection. And with no protocol to control communication software easily. The following gives details of each command. Absolute move: M

Go to location. Due to internal operations, possible values ??are 0 to 32767. Relative movement: + , -

From the current position + / - step moves. Possible values ??are 0 to 65536. Homing: R

Set the location counter value to return to the origin. The velocity at a constant rate 200pps, ORG to reverse feed input until it detects, and then sending in order to finish until the ORG input. Usually omit the (0). Set location counter: P

Set the location counter value. 0 is equivalent to setting the value is omitted. Set velocity: V

Set the moving speed. The range is from 0 to 31, 166pps ~ 1266pps unit corresponds to 33pps. Acceleration setting: A

Set the acceleration at starting and stopping. The range is from 0 to 15, the higher the gradual acceleration and deceleration values. Excitation system settings: M

Set the mode of excitation pulse motor. Value between 0 and 3, see below. Excitation ON / OFF: D

Excitation of the motor output to the ON / OFF. The 0 OFF (default), and is 1 ON. OFF command to move if they get in the ON state. Given the disabling pulse excitation mode, this command 3. Step movement: "<", ">"

Run this command immediately upon receiving the letter 1 (CR is not required.) "<" A step backward feed, the ">" The Advance in 1 step.

Parameters read: "?" P-value, V value, A value, M value is read. Store operating parameters: "_" Value V, A value, M value stored in the EEPROM. This defaults to the next startup. Sudden stop Break during the move command signal transfer system (20ms or more) to send immediate stop. Return value After the process returns the result code for each command. Support the values ??and meanings are as follows. 🔗 External reference

- Absolute move: M <n> - Go to <n> location, possible values are 0 to 32767.

- Relative movement: + <n>, - <n> - From the current position +/- <n> step moves, possible values are 0 to 65536.

- Homing: R <n> - Set the location counter value to return to the origin at a constant rate of 200pps, reverse feed input until detection, then finish until the origin input. Usually, omit the (0).

- Set location counter: P <n> - Set the location counter value, 0 is equivalent to setting the value omitted.

- Set velocity: V <n> - Set the moving speed, range from 0 to 31, corresponding to 166pps ~ 1266pps unit at 33pps.

- Acceleration setting: A <n> - Set acceleration at starting and stopping, range from 0 to 15, higher values indicate gradual acceleration and deceleration.

- Excitation system settings: M <n> - Set the mode of excitation pulse motor, value between 0 and 3.

- Excitation ON/OFF: D <n> - Excitation of the motor output ON/OFF, 0 OFF (default), 1 ON. The OFF command disables pulse excitation mode.

- Step movement: "<", ">" - Run command immediately upon receiving the letter, "<" for step backward, ">" for advance in 1 step.

- Parameters read: "?" - Read P-value, V value, A value, M value.

- Store operating parameters: "_" - Store values V, A, M in EEPROM for next startup.

- Sudden stop - Break during move command signal transfer (20ms or more) for immediate stop.

- Return value - After the process, returns the result code for each command.

The pulse motor system described relies on precise control mechanisms to ensure accurate positioning and movement. The motor operates under a set of commands that dictate its behavior, allowing for both absolute and relative movements. The absolute move command (M <n>) directs the motor to a specific position within a defined range, while relative movements (+ <n> or - <n>) adjust the motor's current position incrementally.

The homing command (R <n>) is crucial for establishing a reference point for the motor's movements, ensuring that the system can return to a known state. The speed of the motor can be adjusted through the velocity command (V <n>), which allows for fine-tuning of performance based on application requirements. This is complemented by the acceleration setting (A <n>), which controls how quickly the motor can start and stop, thus enhancing operational efficiency.

The excitation system settings (M <n>) and excitation ON/OFF commands (D <n>) provide flexibility in how the motor is powered, allowing for different operational modes depending on the task at hand. Step movement commands ("<" and ">") enable immediate response to control inputs, providing real-time adjustments to the motor's position.

The ability to read parameters with the "?" command and store operating parameters in EEPROM ensures that the system retains its settings across power cycles, enhancing reliability and ease of use. The sudden stop feature allows for immediate cessation of motor activity, which is critical for safety in dynamic environments.

Overall, this pulse motor system is designed for precision control in various applications, leveraging a robust command set to enable flexible operation and efficient performance.The first pulse motor that is used to diss it because it is the positioning control things, we decided to incorporate features that may be needed for positioning control. This does not mean that intelligent, and autonomous driving the motor in response to movement commands from the host.

The key to controlling the pulse motor, the stall is to prevent slowly varying speed during starting and stopping, and of course also be applied to control and became a highlight of this feature. The parameters required for control (such as maximum speed, acceleration, excitation system) to be able to change the command.

And the host controller sends commands to the RS232C connection. And with no protocol to control communication software easily. The following gives details of each command. Absolute move: M

Parameters read: "?" P-value, V value, A value, M value is read. Store operating parameters: "_" Value V, A value, M value stored in the EEPROM. This defaults to the next startup. Sudden stop Break during the move command signal transfer system (20ms or more) to send immediate stop. Return value After the process returns the result code for each command. Support the values ??and meanings are as follows. 🔗 External reference