converter r2elhc600a 10v

A medium current switch mode power converter is designed to power superconducting loads that require both positive and negative current and voltage control, operating across four quadrants. The system is built on a modular architecture consisting of two [+/-400A +10V] power modules that offer active redundancy, allowing it to typically provide the necessary current to the load, even with just one power module in operation. This converter is primarily utilized in irradiated locations of the LHC particle accelerator, where redundancy and radiation tolerance are essential. The unit is water-cooled, making it suitable for environments where air losses must be minimized. It is designed for underground use and features extensive remote diagnostics for efficient monitoring and fault diagnosis without the need for on-site presence. The power component functions as a four-quadrant voltage source, although an internal current source control is necessary to effectively share output current between the power modules. Each power module operates as a high-frequency fully bidirectional current source (+/-400A +/-10V) at a frequency of 7-8kHz, controlled by a voltage loop with a bandwidth of 1kHz. The module's structure includes voltage source capacitors for mechanical reasons, despite its current source functionality. The representation of the power converter illustrates its symbolic structure and cascade loops. The multiple rectifier stages in each output module provide several advantages, including simpler design of magnetic components and lower-rated fuses, which reduce losses and protect the entire power converter from short circuits caused by faulty secondary components. In such cases, the fuse will blow immediately, allowing the power converter to reconfigure current levels in other sources to maintain the required voltage. Redundant operation primarily relies on the reactivity of the inner current source rated at [+/-400A +/-10V] and is significantly affected by the output current level (limited to 400A), ensuring that the load output current remains unaffected by the failure of one sub-module. However, a sudden short circuit at the output stage of a sub-converter will result in a global fault stop of the converter. The high precision current control loop is managed by a digital controller known as the Function Generator Controller (FGC). This unit incorporates a high precision Sigma-Delta Analog to Digital Converter that digitizes the analog current measurements obtained from two DC current transducers (DCCTs). The overall precision of the system is contingent upon the accuracy of the sensors, ADCs, and the algorithms employed in the regulation loop. The voltage source acts as a power amplifier, supplying the load via a high-bandwidth voltage loop with a frequency greater than 500Hz. The power converter is part of the magnet protection scheme, although it is not solely responsible for monitoring and diagnosing the status of the superconducting magnets. Dedicated systems such as the Quench Protection System (QPS) and the Power Interlock Controller (PIC) can interlock the power converter if magnet safety necessitates such action. It is crucial to ensure that the external protection system can halt the power converter through a safe signal known as Fast Abort. This redundant signal utilizes two pathways to interlock and stop the converter, with its redundancy verified each time it is activated. It directly impacts the AC and DC contactor coils, ensuring they open as required to safely stop powering the load while managing the magnet's energy through a dedicated system known as a crowbar. This active system, combined with the presence of DC contactors in the rack, provides a safe resistive discharge path for the magnet current. The system operates based on a series configuration of 50 mOhm power resistances and back-to-back thyristors that are triggered at a specified output voltage.A medium current switch mode power converter, designed for powering of superconducting loads requiring positive or negative current and positive or negative voltage control (4 quadrants). Constructed from a modular architecture composed of 2x [+/-400A +10V] power modules (active redundancy), the system can most of the time provide required current

to the load since often less than |400A|, even with 1 Power Module only. Primary use is in LHC particle accelerator irradiated locations (redundancy and Radiation tolerant). The converter is water cooled, and is thus ideally suited to situations where air losses must be carefully managed. Designed for underground operation, extensive remote diagnostics have been foreseen to allow efficient monitoring and fault diagnostics without requiring being present locally.

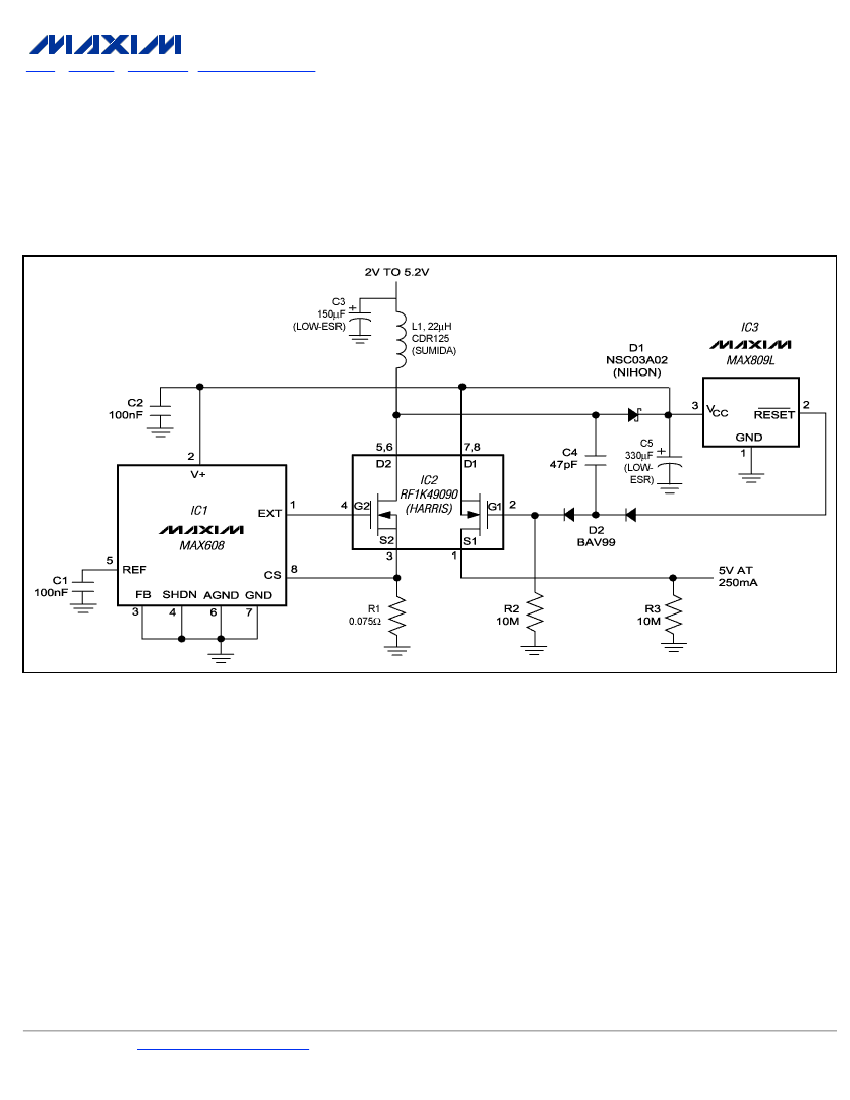

Power part is identified as a 4 quadrant voltage source, even if an internal current source control is required to adequately share output current between power modules. Power Module is actually a high frequency fully bidirectionnal (+/-400A +/-10V) current source (7-8kHz) controlled by a 1kHz bandwidth voltage loop.

One can notice that Power Module is actually a current cource in its structure, even if voltage source capacitors are located in this block for mechanical reasons. Representation below gives a symbolic structure of the power converter, clarifying the cascade loops.

The multiplication of rectifier stages in each output module gives the following advantages: easier design of magnetic parts, lower rating fuse (lower losses) to protect whole Power Converter being short-circuited by a faulty secondary (fuse would immediately blow in case one of the schottky dies, giving the possibility to the whole power converter to reconfigure the current level in other current sources to maintain required voltage level). Redundance operation relies mainly on [+/-400A +/-10V] inner current source reactivity, and strongly depends of the output current level (400A limit), so that load output current is not impacted by the loss of one sub.

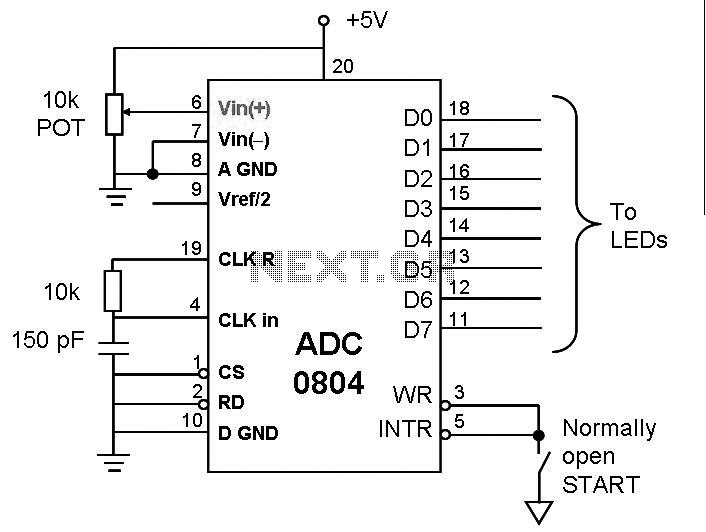

Of course a sudden short at the level of the output stage of a sub converter will lead to a converter global fault stop. High precision current control loop is managed by the digital controller called FGC (Function Generator Controller).

This unit includes a high precision Sigma Delta Analog to Digital Converter which digitalize the analog current measurement coming from 2 DCCTs (DC current Transducer). Precision is then directly relying on sensor precision: DCCT, the ADCs, and the algorithm being used for the regulation loop.

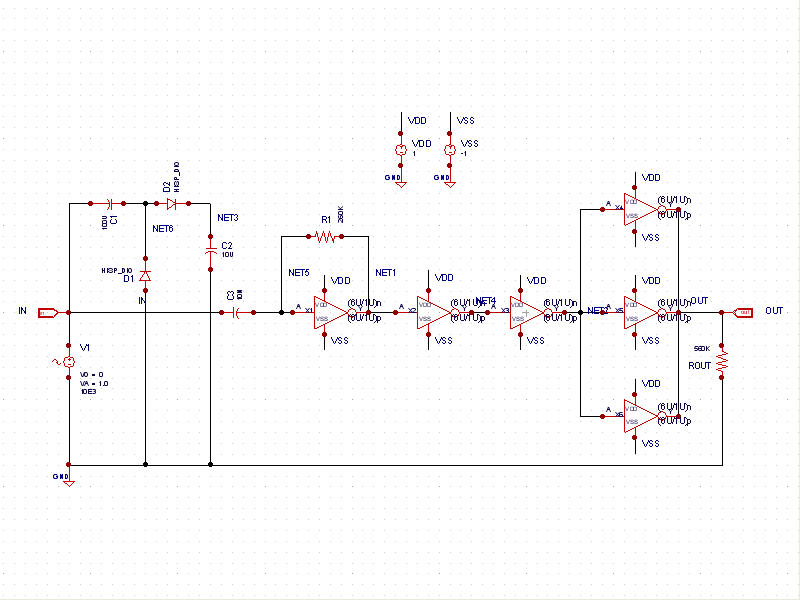

Voltage source is then used as a power amplifier, powering the load through a high bandwidth voltage loop (>500Hz). Power Converter is part of magnet protection scheme, even if not directly fully responsible of the monitoring and diagnostic of the superconductive magnet status.

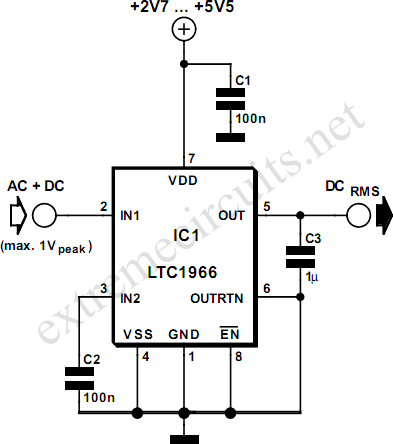

Dedicated systems QPS (Quench Protection System) + PIC (Power Interlock Controller) can interlock Power Converter if magnet safety requires it. Always ensure that external protection system can stop the Power Converter through a safe signal called Fast Abort.

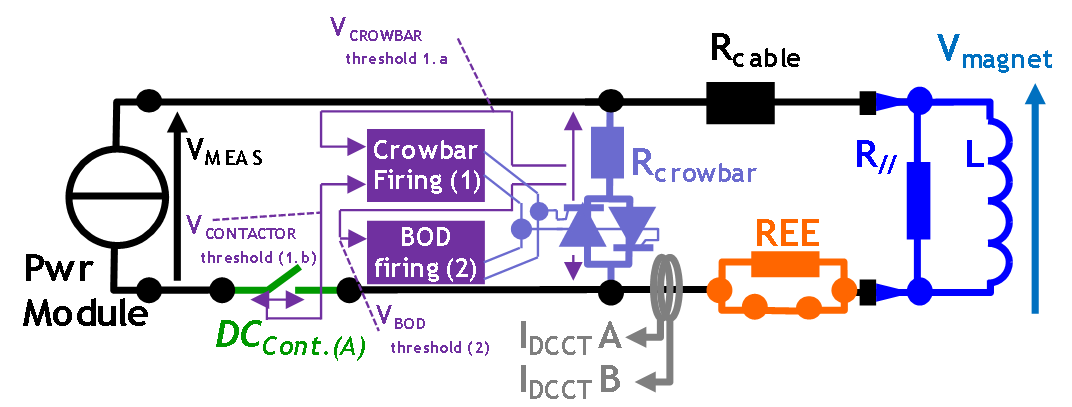

This redundant signal uses 2 paths to interlock and stop the converter and its redundancy is checked each time it acts. It directly acts on AC and DC Contactor bobbin, ensuring their opening as required. Stop powering the load in safe way (handling the magnet energy even when stopping, through dedicated system called crowbar).

This active system combined with the presence of DC-Contactors in the rack provide a safe resistive discharge path for magnet current (energy). The system is based on a 50 mOhms Power Resistance series back-to-back thyristors being fired at a given output voltage (

🔗 External reference

to the load since often less than |400A|, even with 1 Power Module only. Primary use is in LHC particle accelerator irradiated locations (redundancy and Radiation tolerant). The converter is water cooled, and is thus ideally suited to situations where air losses must be carefully managed. Designed for underground operation, extensive remote diagnostics have been foreseen to allow efficient monitoring and fault diagnostics without requiring being present locally.

Power part is identified as a 4 quadrant voltage source, even if an internal current source control is required to adequately share output current between power modules. Power Module is actually a high frequency fully bidirectionnal (+/-400A +/-10V) current source (7-8kHz) controlled by a 1kHz bandwidth voltage loop.

One can notice that Power Module is actually a current cource in its structure, even if voltage source capacitors are located in this block for mechanical reasons. Representation below gives a symbolic structure of the power converter, clarifying the cascade loops.

The multiplication of rectifier stages in each output module gives the following advantages: easier design of magnetic parts, lower rating fuse (lower losses) to protect whole Power Converter being short-circuited by a faulty secondary (fuse would immediately blow in case one of the schottky dies, giving the possibility to the whole power converter to reconfigure the current level in other current sources to maintain required voltage level). Redundance operation relies mainly on [+/-400A +/-10V] inner current source reactivity, and strongly depends of the output current level (400A limit), so that load output current is not impacted by the loss of one sub.

Of course a sudden short at the level of the output stage of a sub converter will lead to a converter global fault stop. High precision current control loop is managed by the digital controller called FGC (Function Generator Controller).

This unit includes a high precision Sigma Delta Analog to Digital Converter which digitalize the analog current measurement coming from 2 DCCTs (DC current Transducer). Precision is then directly relying on sensor precision: DCCT, the ADCs, and the algorithm being used for the regulation loop.

Voltage source is then used as a power amplifier, powering the load through a high bandwidth voltage loop (>500Hz). Power Converter is part of magnet protection scheme, even if not directly fully responsible of the monitoring and diagnostic of the superconductive magnet status.

Dedicated systems QPS (Quench Protection System) + PIC (Power Interlock Controller) can interlock Power Converter if magnet safety requires it. Always ensure that external protection system can stop the Power Converter through a safe signal called Fast Abort.

This redundant signal uses 2 paths to interlock and stop the converter and its redundancy is checked each time it acts. It directly acts on AC and DC Contactor bobbin, ensuring their opening as required. Stop powering the load in safe way (handling the magnet energy even when stopping, through dedicated system called crowbar).

This active system combined with the presence of DC-Contactors in the rack provide a safe resistive discharge path for magnet current (energy). The system is based on a 50 mOhms Power Resistance series back-to-back thyristors being fired at a given output voltage (

🔗 External reference