DC motor speed control using 8051 and l298

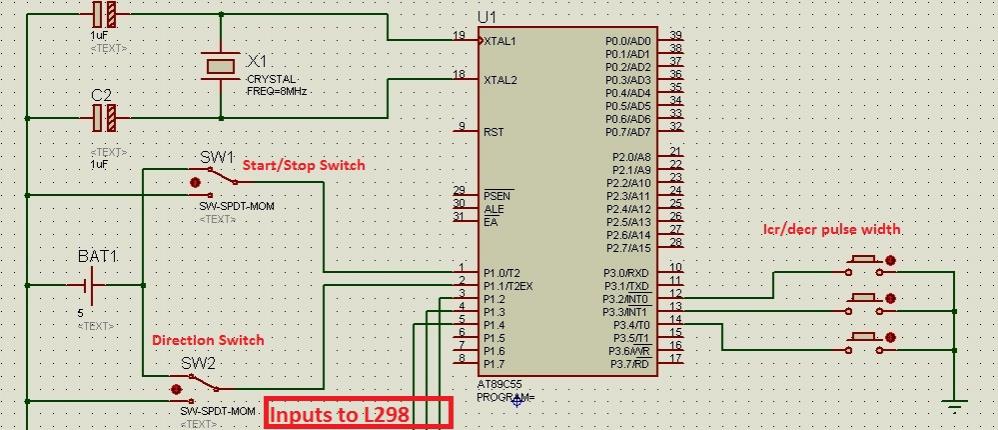

Greetings to all! A new user is exploring microcontrollers and is utilizing the AT89C55WD microcontroller to control an H-Bridge (L298), which subsequently drives a DC motor. The circuits for this setup are...

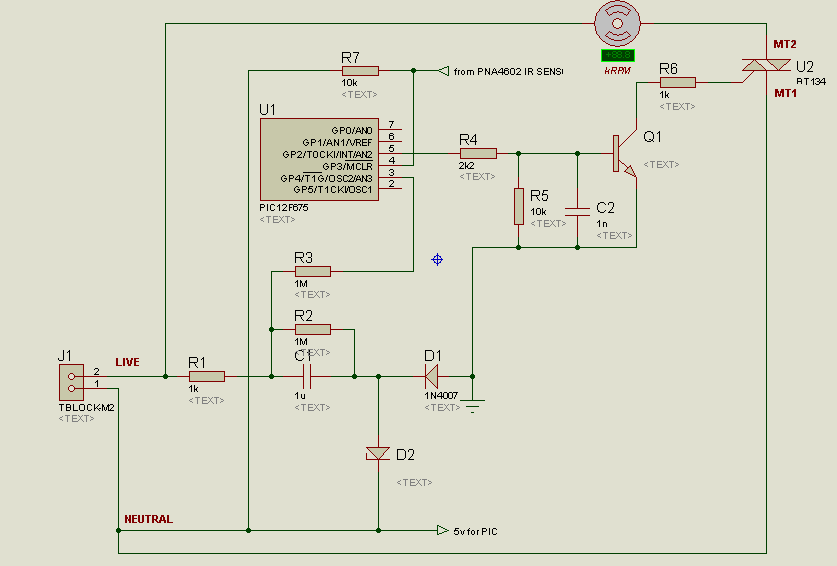

The AT89C55WD microcontroller is an 8-bit microcontroller from the 8051 family, featuring a 40-pin dual in-line package (DIP) design. It is equipped with 32 I/O lines, two 16-bit timers/counters, and a full-duplex UART for serial communication. This microcontroller is well-suited for applications requiring precise control and interfacing with various peripherals.

In this application, the AT89C55WD interfaces with an L298 H-Bridge driver. The L298 is a dual H-Bridge motor driver capable of driving two DC motors or one stepper motor. The H-Bridge configuration allows for bidirectional control of the motors, enabling forward and reverse operation. The L298 can handle up to 2A of continuous current per channel and is suitable for motors operating at voltages ranging from 5V to 46V.

The circuit design involves connecting the output pins of the AT89C55WD to the input pins of the L298. Typically, four control pins are used to manage the two motors: two for each motor's direction and two for enabling the motors. PWM (Pulse Width Modulation) signals can be generated by the microcontroller to control the speed of the DC motors by varying the duty cycle of the signals sent to the enable pins of the L298.

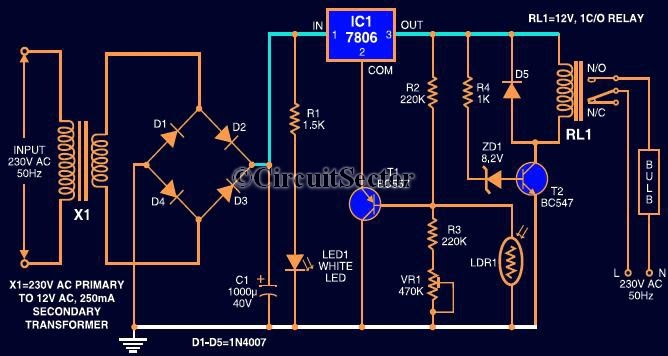

Power supply considerations are critical in this setup. The microcontroller should be powered with a stable voltage, typically 5V, while the L298 should be connected to a suitable power source that matches the motor's voltage requirements. It is also advisable to include decoupling capacitors near the power pins of both the microcontroller and the L298 to filter out noise and ensure stable operation.

In summary, this configuration leverages the AT89C55WD microcontroller's capabilities to control an L298 H-Bridge driver, allowing for effective management of DC motors in various applications, including robotics and automation systems. Proper circuit design and component selection are essential for achieving reliable performance in the intended application.Hi Everyone out there! I am new to microcontrollers. I am using AT89C55WD to control H-Bridge (L298) which in turn drives the DC motor. Circuits for.. 🔗 External reference

The AT89C55WD microcontroller is an 8-bit microcontroller from the 8051 family, featuring a 40-pin dual in-line package (DIP) design. It is equipped with 32 I/O lines, two 16-bit timers/counters, and a full-duplex UART for serial communication. This microcontroller is well-suited for applications requiring precise control and interfacing with various peripherals.

In this application, the AT89C55WD interfaces with an L298 H-Bridge driver. The L298 is a dual H-Bridge motor driver capable of driving two DC motors or one stepper motor. The H-Bridge configuration allows for bidirectional control of the motors, enabling forward and reverse operation. The L298 can handle up to 2A of continuous current per channel and is suitable for motors operating at voltages ranging from 5V to 46V.

The circuit design involves connecting the output pins of the AT89C55WD to the input pins of the L298. Typically, four control pins are used to manage the two motors: two for each motor's direction and two for enabling the motors. PWM (Pulse Width Modulation) signals can be generated by the microcontroller to control the speed of the DC motors by varying the duty cycle of the signals sent to the enable pins of the L298.

Power supply considerations are critical in this setup. The microcontroller should be powered with a stable voltage, typically 5V, while the L298 should be connected to a suitable power source that matches the motor's voltage requirements. It is also advisable to include decoupling capacitors near the power pins of both the microcontroller and the L298 to filter out noise and ensure stable operation.

In summary, this configuration leverages the AT89C55WD microcontroller's capabilities to control an L298 H-Bridge driver, allowing for effective management of DC motors in various applications, including robotics and automation systems. Proper circuit design and component selection are essential for achieving reliable performance in the intended application.Hi Everyone out there! I am new to microcontrollers. I am using AT89C55WD to control H-Bridge (L298) which in turn drives the DC motor. Circuits for.. 🔗 External reference