Digital Bike Tachometer Circuit

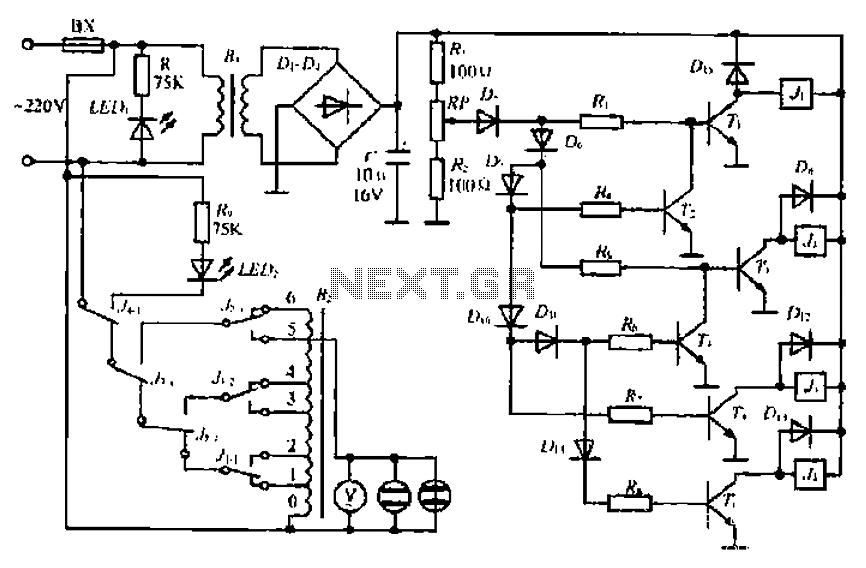

This digital DIY tachometer for bicycles utilizes two reed switches to gather speed information. The reed switches are positioned near the wheel rim, where permanent magnets are mounted on the wheel spokes. As the spokes rotate, the magnets pass by the reed switches, activating them. The speed is displayed digitally. The tachometer functions by counting the pulses generated by the reed switches over a specified time interval. This count is then displayed to represent the bicycle's speed. Two 4026 integrated circuits (ICs) are employed to count the pulses, decode the counter, and control two 7-segment LED displays. RS flip-flops U3 and U4 serve as anti-bounce mechanisms. The pulses reach the counter input through gate U7. The measurement period is determined by a monostable multivibrator formed by U5 and U6, which can be adjusted via potentiometer P1 for calibration purposes. The circuit comprising U1 and U2 resets the counters. Since the circuit is powered by batteries, continuous display of speed information is impractical, and it is only activated when a button is pressed. A minimum of three permanent magnets must be installed on the wheel, and the circuit can be calibrated using a pre-calibrated tachometer.

This digital DIY tachometer circuit is designed to provide an accurate speed measurement for bicycles using a straightforward and effective mechanism. The integration of two reed switches allows for reliable detection of the wheel's rotation as the permanent magnets pass by. This approach minimizes mechanical wear and enhances the durability of the system. The use of two 4026 ICs enables efficient pulse counting and decoding, which is essential for translating the mechanical motion into a readable digital format.

The anti-bounce feature provided by the RS flip-flops U3 and U4 is crucial for ensuring that only valid pulses are counted, thereby improving the accuracy of speed readings. Gate U7 facilitates the flow of pulses to the counting mechanism, ensuring that the system responds promptly to the activation of the reed switches. The monostable multivibrator configuration using U5 and U6 is particularly beneficial, as it allows the user to set the measurement interval, thus accommodating different types of bicycles and riding conditions. The inclusion of potentiometer P1 for calibration purposes ensures that the tachometer can be fine-tuned for optimal performance.

The design prioritizes battery efficiency by activating the circuit only when needed, which prolongs battery life and reduces the frequency of replacements. The requirement for at least three permanent magnets ensures that the system receives sufficient input for accurate speed calculations, while also allowing for a margin of error in the event that one magnet does not trigger a reed switch. The ability to calibrate the circuit using a pre-calibrated tachometer adds a layer of precision, making this DIY project suitable for hobbyists and cycling enthusiasts who seek to enhance their biking experience with reliable speed measurements.This digital DIY tachometer for bikes uses two reed switches to get the speed information of the bicycle. The reed switches are installed near the rim of the wheel where permanent magnets pass by. The permanent magnets are attached to the wheelspokes and activate the reed switches everytime they pass by it.

The speed is digitally displayed. The ta chometer circuit works according to this principle; the pulses created by the reed contacts are counted within a certain time interval. The resulting count is then displayed and represents the speed of the bike. Two 4026 ICs are used to count the pulses, decode the counter and control two 7-segment LED display. RS flip-flops U3 and U4 function as anti-bounce. The pulses arrive at the counter`s input through gate U7. The measuring period is determined by monostable multivibrator U5/U6 and can be adjusted through potentiometer P1 so that the tacho can be calibrated.

The circuit U1/U2 resets the counters. Since batteries are used to power the circuit, it is not practical to support the continous display of speed information. This circuit is not continously active. The circuit is activated only after a button is pressed. At least three permanent magnets must be installed on the wheel. The circuit can be calibrated with the help of another precalibrated tachometer. 🔗 External reference

This digital DIY tachometer circuit is designed to provide an accurate speed measurement for bicycles using a straightforward and effective mechanism. The integration of two reed switches allows for reliable detection of the wheel's rotation as the permanent magnets pass by. This approach minimizes mechanical wear and enhances the durability of the system. The use of two 4026 ICs enables efficient pulse counting and decoding, which is essential for translating the mechanical motion into a readable digital format.

The anti-bounce feature provided by the RS flip-flops U3 and U4 is crucial for ensuring that only valid pulses are counted, thereby improving the accuracy of speed readings. Gate U7 facilitates the flow of pulses to the counting mechanism, ensuring that the system responds promptly to the activation of the reed switches. The monostable multivibrator configuration using U5 and U6 is particularly beneficial, as it allows the user to set the measurement interval, thus accommodating different types of bicycles and riding conditions. The inclusion of potentiometer P1 for calibration purposes ensures that the tachometer can be fine-tuned for optimal performance.

The design prioritizes battery efficiency by activating the circuit only when needed, which prolongs battery life and reduces the frequency of replacements. The requirement for at least three permanent magnets ensures that the system receives sufficient input for accurate speed calculations, while also allowing for a margin of error in the event that one magnet does not trigger a reed switch. The ability to calibrate the circuit using a pre-calibrated tachometer adds a layer of precision, making this DIY project suitable for hobbyists and cycling enthusiasts who seek to enhance their biking experience with reliable speed measurements.This digital DIY tachometer for bikes uses two reed switches to get the speed information of the bicycle. The reed switches are installed near the rim of the wheel where permanent magnets pass by. The permanent magnets are attached to the wheelspokes and activate the reed switches everytime they pass by it.

The speed is digitally displayed. The ta chometer circuit works according to this principle; the pulses created by the reed contacts are counted within a certain time interval. The resulting count is then displayed and represents the speed of the bike. Two 4026 ICs are used to count the pulses, decode the counter and control two 7-segment LED display. RS flip-flops U3 and U4 function as anti-bounce. The pulses arrive at the counter`s input through gate U7. The measuring period is determined by monostable multivibrator U5/U6 and can be adjusted through potentiometer P1 so that the tacho can be calibrated.

The circuit U1/U2 resets the counters. Since batteries are used to power the circuit, it is not practical to support the continous display of speed information. This circuit is not continously active. The circuit is activated only after a button is pressed. At least three permanent magnets must be installed on the wheel. The circuit can be calibrated with the help of another precalibrated tachometer. 🔗 External reference