Digitally controlled threshold detector

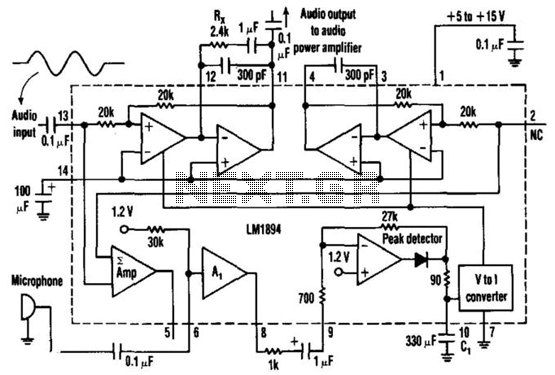

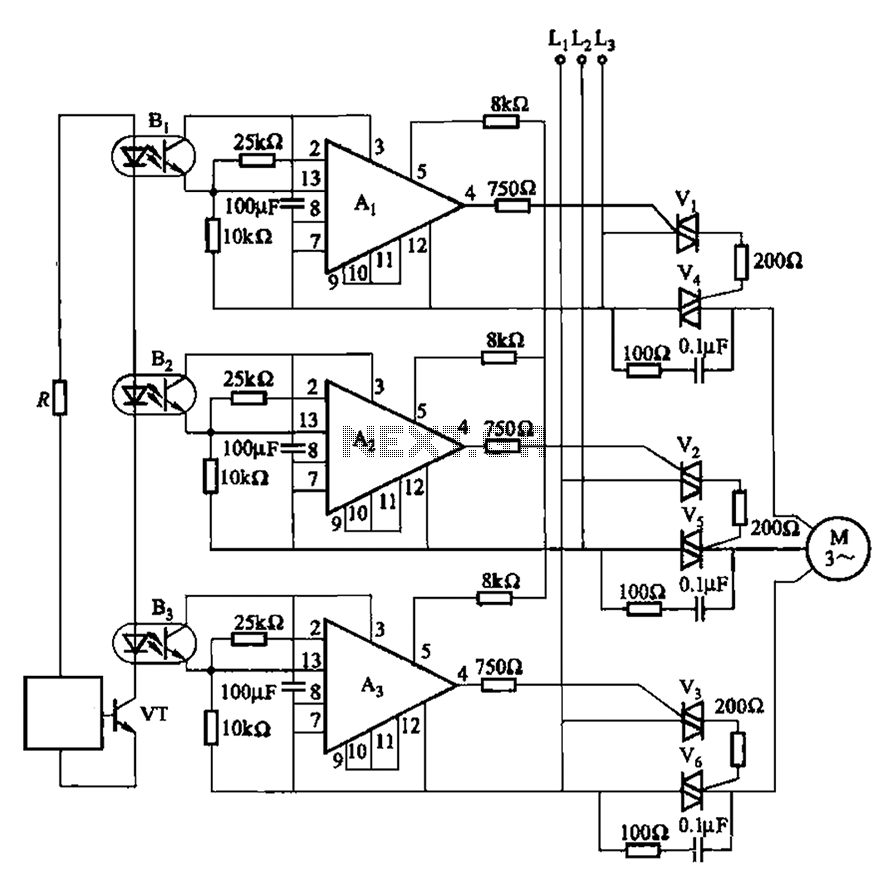

This circuit utilizes small switching transistors, with a maximum motor drive current limited to approximately 250 mA at 5V. Testing has been conducted across a voltage range from 3V to 21V, and with certain component modifications, it may be applicable for use up to 63V in a 36V photovoltaic (PV) panel system, although this has not yet been tested. With higher voltages and the addition of heat sinks on the bridge transistors, significantly higher currents may be achievable. Circuit 1 tends to cause relays to chatter under specific lighting conditions due to the absence of built-in hysteresis. A Schmitt trigger hex inverter circuit has been introduced in this version to mitigate the chatter, improving performance despite increased complexity. Resistors R4 and R5 are employed to enforce parking when ambient light diminishes; however, they may reduce sensitivity and should be omitted in low power consumption applications if parking is not desired. Efforts have been made to develop low-cost yet accurate conventional solar trackers. While the CdS tracker performs adequately, it lacks precision and sensitivity. An exploration into using PV cells as sensors led to the discovery that LEDs generate voltage when exposed to sunlight, with green LEDs producing around 1.65V to 1.74V, significantly more than the 0.55V from silicon PV cells. This phenomenon is attributed to the higher bandgap voltage of Gallium Phosphide, the material used in green LEDs. Initial experiments involved using a low threshold MOSFET (BS107PT) to create a switching mechanism powered by two back-to-back LEDs, where the LED receiving more light intensity would control the MOSFET. The circuit configuration includes three power supply LEDs oriented towards East, Up, and West, while sensor LEDs are placed approximately 90 degrees apart and 45 degrees from the vertical. This arrangement creates a dead zone at the center where tracking ceases. The system exhibits high sensitivity, returning the panel to the East shortly after sunrise, with good calibration potential through LED adjustment. However, the proof of concept risks burning relay contacts due to slow activation, leading to potential damage. Limit switches are essential for servo motor operation in solar trackers. The provided diagram illustrates their function: during normal operation, both limit switches are closed; if the left limit switch opens, movement to the left ceases, and a diode allows right movement; conversely, if the right limit switch opens, left movement is enabled through the diode. Selection of a diode or rectifier should accommodate the maximum motor current with an adequate safety margin, and voltage ratings should be at least 100V, ideally 200V. It is critical that limit switches activate before mechanical limits are reached to prevent excessive current draw that could damage the solar tracker.

The circuit described is a sophisticated solar tracking system that integrates various electronic components to enhance performance and reliability. The use of small switching transistors ensures efficient control of motor drive currents, while the potential for operation at higher voltages allows for flexibility in different solar panel configurations. The implementation of a Schmitt trigger hex inverter circuit effectively addresses issues of relay chatter, which can compromise the functionality of the system under variable lighting conditions.

Incorporating LEDs as voltage-generating sensors represents an innovative approach to solar tracking, leveraging the unique properties of Gallium Phosphide to achieve higher voltage outputs compared to traditional silicon PV cells. This method not only improves sensitivity but also provides a cost-effective solution for solar tracking applications. The design allows for precise calibration, enabling the system to adjust its orientation effectively in response to sunlight.

The inclusion of limit switches is a critical safety feature that prevents mechanical overloads by ensuring that motor movement is halted before reaching physical constraints. The diagram illustrating the operation of these switches provides a clear understanding of their role in the circuit, emphasizing the importance of selecting appropriate components to handle the expected electrical loads.

Overall, this circuit exemplifies the integration of advanced electronic principles to create a functional and efficient solar tracking system, demonstrating potential for both commercial and experimental applications in renewable energy technologies.This circuit uses small switching transistors. The maximum motor drive current is limited to about 250mA maximum at 5V. I`ve tested the circuit on voltages from 3V to 21V. With some component changes it should be usefulto 63V in a 36V PV panel system although I haven`t tried this yet. With higher voltage and the use of heat sinks on the bridge transistors much higher currents should be possible.

(View) Circuit 1 tends to chatter the relays under certain lighting conditions as there is no built in hysteresis. This version uses a Schmitt trigger hex inverter circuit to eliminate the chatter. It works better but is more complex. Note! R4 and R5 are used to force parking when it gets dark. If parking is not desired don`t use R4 and R5. Parking may not be desired in low power consumption applications. Also, the parking resistors, R4 and R5, reduce sensitivity a bit. (View) I have been looking for truly low cost and yet accurate conventional solar trackers. The CdS tracker is pretty good but lacks accuracy and sensitivity. I was thinking about using PV cells as the sensor. I was experimenting with LEDs and noticed they generate voltage in sunlight. Bingo! This got me to thinking. They generate quite a bit of voltage. The green ones generate about 1. 65V, some as much a 1. 74V. Not the piddley. 55 volts of a silicon PV cell. How is this so Well, it turns out green LEDs are made from Gallium Phosphide, a semiconductor with a much higher bandgap voltage.

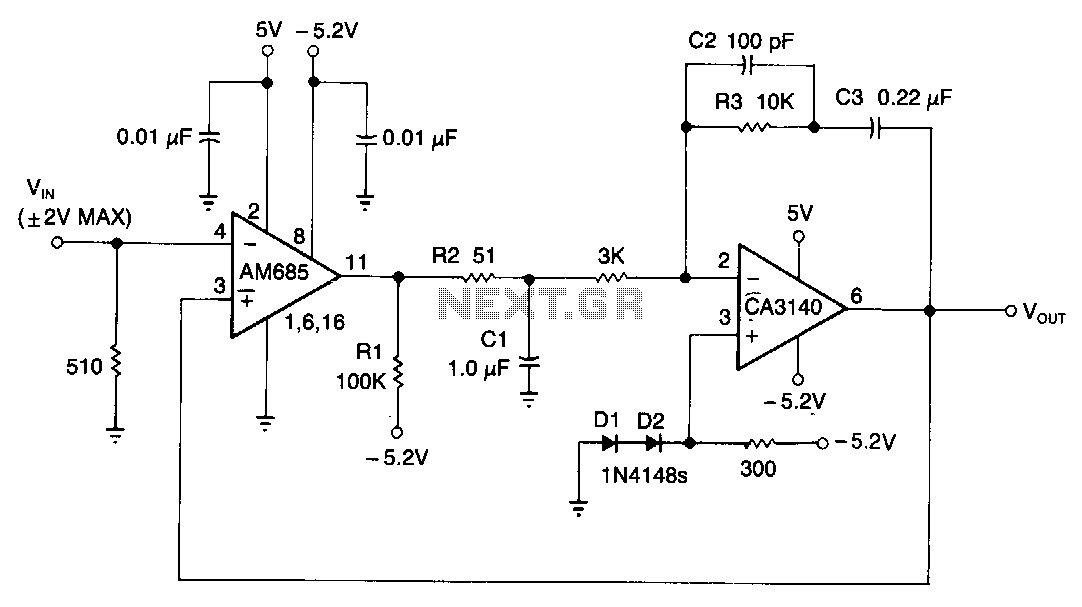

I thought I had invented the use of LEDs as PV cells as I had never heard of this effect before. Well, after some investigating I found a number of references to this. The guys that had done the most work in this area were the people form the BEAM project. They make tiny solar powered robots and some used LED photo sensors. I had been using a very low threshold MOSFET in a TO-92 package, BS107PT. The threshold is about 1. 5V. If I put two LEDs back to back, one fighting the other, the one with more light intensity wins. I thought I could use this to switch the MOSFET. And it worked. By using one LED as a sort of power supply and the back to back pair connected from it to the MOSFET gate the circuit is complete. (This I have not seen elsewhere. ) My implementation uses three power supply LEDs, aimed East, Up, and West. The sensor LEDs are aimed about 90 °s from each other and at about 45 °s either side of up. Of course the easterly pair will be a little to the East and the westerly pair a little to the West. This makes the center have a dead zone where tracking stops. The circuit is quite sensitive. It brings the panel back to the East just after sun rise. The accuracy is quite good. You can calibrate the sensor by bending or aiming the LEDs a bit. While the proof of concept is good it will burn the relay contacts, similar to that on the Cadmium Sulfide tracker.

This is caused by the relays being turned on or off slowly. It melted the plastic case on the relays. (View) Limit switches are essential for servo motor operation with solar trackers. I made this diagram to help explain how they work. Top. Normal operation between limit switches. Middle. The left limit switch has opened to stop movement to the left. To move to the right again the diode conducts current that allows movement to the right. Bottom. The right limit switch has opened to stop movement to the right. To move to the left again the diode conducts current that allows movement to the left. Sellect a diode or rectifier rated at the maximum motor current plus some margine. Also the voltage should be at leat 100V and preferably 200V. Needles to say, the limit switch must operate before the mechanical limits are reached. If the mechanical stop is reached before the switch the motor can draw quite high currents and can destroy the solar t 🔗 External reference

The circuit described is a sophisticated solar tracking system that integrates various electronic components to enhance performance and reliability. The use of small switching transistors ensures efficient control of motor drive currents, while the potential for operation at higher voltages allows for flexibility in different solar panel configurations. The implementation of a Schmitt trigger hex inverter circuit effectively addresses issues of relay chatter, which can compromise the functionality of the system under variable lighting conditions.

Incorporating LEDs as voltage-generating sensors represents an innovative approach to solar tracking, leveraging the unique properties of Gallium Phosphide to achieve higher voltage outputs compared to traditional silicon PV cells. This method not only improves sensitivity but also provides a cost-effective solution for solar tracking applications. The design allows for precise calibration, enabling the system to adjust its orientation effectively in response to sunlight.

The inclusion of limit switches is a critical safety feature that prevents mechanical overloads by ensuring that motor movement is halted before reaching physical constraints. The diagram illustrating the operation of these switches provides a clear understanding of their role in the circuit, emphasizing the importance of selecting appropriate components to handle the expected electrical loads.

Overall, this circuit exemplifies the integration of advanced electronic principles to create a functional and efficient solar tracking system, demonstrating potential for both commercial and experimental applications in renewable energy technologies.This circuit uses small switching transistors. The maximum motor drive current is limited to about 250mA maximum at 5V. I`ve tested the circuit on voltages from 3V to 21V. With some component changes it should be usefulto 63V in a 36V PV panel system although I haven`t tried this yet. With higher voltage and the use of heat sinks on the bridge transistors much higher currents should be possible.

(View) Circuit 1 tends to chatter the relays under certain lighting conditions as there is no built in hysteresis. This version uses a Schmitt trigger hex inverter circuit to eliminate the chatter. It works better but is more complex. Note! R4 and R5 are used to force parking when it gets dark. If parking is not desired don`t use R4 and R5. Parking may not be desired in low power consumption applications. Also, the parking resistors, R4 and R5, reduce sensitivity a bit. (View) I have been looking for truly low cost and yet accurate conventional solar trackers. The CdS tracker is pretty good but lacks accuracy and sensitivity. I was thinking about using PV cells as the sensor. I was experimenting with LEDs and noticed they generate voltage in sunlight. Bingo! This got me to thinking. They generate quite a bit of voltage. The green ones generate about 1. 65V, some as much a 1. 74V. Not the piddley. 55 volts of a silicon PV cell. How is this so Well, it turns out green LEDs are made from Gallium Phosphide, a semiconductor with a much higher bandgap voltage.

I thought I had invented the use of LEDs as PV cells as I had never heard of this effect before. Well, after some investigating I found a number of references to this. The guys that had done the most work in this area were the people form the BEAM project. They make tiny solar powered robots and some used LED photo sensors. I had been using a very low threshold MOSFET in a TO-92 package, BS107PT. The threshold is about 1. 5V. If I put two LEDs back to back, one fighting the other, the one with more light intensity wins. I thought I could use this to switch the MOSFET. And it worked. By using one LED as a sort of power supply and the back to back pair connected from it to the MOSFET gate the circuit is complete. (This I have not seen elsewhere. ) My implementation uses three power supply LEDs, aimed East, Up, and West. The sensor LEDs are aimed about 90 °s from each other and at about 45 °s either side of up. Of course the easterly pair will be a little to the East and the westerly pair a little to the West. This makes the center have a dead zone where tracking stops. The circuit is quite sensitive. It brings the panel back to the East just after sun rise. The accuracy is quite good. You can calibrate the sensor by bending or aiming the LEDs a bit. While the proof of concept is good it will burn the relay contacts, similar to that on the Cadmium Sulfide tracker.

This is caused by the relays being turned on or off slowly. It melted the plastic case on the relays. (View) Limit switches are essential for servo motor operation with solar trackers. I made this diagram to help explain how they work. Top. Normal operation between limit switches. Middle. The left limit switch has opened to stop movement to the left. To move to the right again the diode conducts current that allows movement to the right. Bottom. The right limit switch has opened to stop movement to the right. To move to the left again the diode conducts current that allows movement to the left. Sellect a diode or rectifier rated at the maximum motor current plus some margine. Also the voltage should be at leat 100V and preferably 200V. Needles to say, the limit switch must operate before the mechanical limits are reached. If the mechanical stop is reached before the switch the motor can draw quite high currents and can destroy the solar t 🔗 External reference