Downlink Project Description

The Skeyeball project is an ongoing initiative within the Indiana University System Design Methods Laboratory, aimed at providing graduate and undergraduate students with opportunities to engage in embedded system design and implement various projects. The downlink segment of the project focuses on transferring data from an aircraft to the ground using a single signal. This project involves re-implementing Prashant Patel's work from the summer of 2000, followed by compacting and debugging the system to achieve optimal performance. The initial phase includes implementing Xilinx code on two Logic Engine Boards to separately host the airborne and ground components, facilitating adequate testing with the RF transmitter and receiver. Additionally, the analog injection and extraction circuits have been redesigned to enhance bandwidth. An NTSC signal is generated by the video source, with horizontal and vertical synchronizing pulses allowing data injection during periods when the video signal is retracing to the top of the screen, which is always black. Data can be injected and subsequently extracted from these locations. After extraction, the video signal is restored to black to prevent any visual artifacts on the monitor. Each field contains ten injection spaces, with a maximum bandwidth of 300 bits per space. The current objective is to establish a 56 kbps downlink, translating to approximately 90 bits per space, with limitations on higher bit rates imposed by the RF transmitter, receiver, and analog circuitry. The maximum achievable bit rate is determined experimentally, and data is monitored using HyperTerminal, where a lower rate is preferable. As additional components of the system become operational, download capabilities can be enhanced. The project is executed in two phases: a testing phase and a final implementation phase. Upon completion, the injection circuitry will be integrated into the aircraft fuselage, while the extraction circuitry will be located on the ground. The provided diagram illustrates how these components fit into the overall system. The injection circuitry will communicate with the tracking component via a serial link, currently configured to receive at 9600 bps, with potential for future increases. The transmitter and receiver handle the video signal containing the embedded data. On the ground side, extracted data can be displayed through HyperTerminal or any other serial interface, while the video signal can be viewed on a monitor. For the testing phase, equipment is set up on two Logic Engines, which offer a solid foundation due to their wire-wrapping capabilities and slots for necessary pins. The MC1489 and MC1488 chips are utilized on the board for serial communication, as they are connected to the serial cables. The analog section, designed by Bryce Himebaugh, is implemented on a breadboard using discrete resistors, capacitors, and transistors to facilitate easy refinements. Following adjustments to resistance and capacitance, the analog section performed as intended. This section receives the video signal and, using a signal sync separator, extracts the vertical and horizontal sync pulses for the digital section, which then receives data during the appropriate vertical retrace pulses. The digital section is implemented on the Xilinx 4010 chip, which provides ample design space and sufficient pins for testing and usage. The clock signal is supplied by the MX045 chip, generating a 20 MHz pulse that is subsequently divided to achieve the desired data pulse rate. The design takes vertical and horizontal sync pulses from the analog section as input, counting these pulses to determine when to output data in the designated spaces.

The Skeyeball project integrates several key components and methodologies to facilitate effective data transfer from an aircraft to the ground. The system architecture includes a combination of analog and digital circuitry, with a focus on optimizing bandwidth for data transmission. The analog circuits are responsible for handling the NTSC video signal, ensuring that data is injected and extracted during non-visible periods of the video frame. The use of Xilinx FPGA technology allows for flexibility and scalability in the digital processing of the signals, accommodating future enhancements in data rates and functionality.

The implementation of the MC1489 and MC1488 chips for serial communication ensures reliable data transfer between the airborne and ground systems. The careful design of the analog section on a breadboard enables iterative testing and refinement, which is crucial for achieving the desired performance levels. The integration of the MX045 clock generator facilitates accurate timing for data transmission, while the Xilinx 4010 chip's capability to process sync pulses enhances the system's efficiency in data handling.

Overall, the Skeyeball project exemplifies a comprehensive approach to embedded system design, combining theoretical knowledge with practical application to achieve a functional and efficient data downlink system. This project not only serves educational purposes for students involved but also contributes to advancements in embedded systems and RF communication technologies.The Skeyeball project is an ongoing project in the Indiana University System Design Methods Laboratory for both graduate and undergraduate students to perform embedded system design and implement various projects. The downlink portion of the project involves transfering data from the plane to the ground by using a single signal.

My downlink p roject involves re-implementing Prashant Patel`s project from thesummer of 2000, then compacting and debugging it to achieve the desired operation. The first step is to implement the xilinx code using two Logic Engine Boards to host the plane and ground implementation seperately so that adequate testing with the RF transmitter and receiver can be accomplished.

I also re-implemented the analog injection and extraction ciruits with new designs to increase bandwidth. A NTSC signal is generated by the video source and it`s horizontal and vertical synchronizing pulses allow data to be injected at spaces in the signal where the video signal is retracing to the top of the screen and is always black.

The data can be injected in these spots and then extracted from the same spot by the same manner. Once the data is extracted, the video signal is set back to black so that there are no side effects in the video image displayed on the monitor. There are 10 of these spaces in each field and a maximum bandwidth of 300 bits per space. The present goal is an established 56kbps downlink, which is around 90 bits per space. The limitation to higher bps is the bandwidth the RF transmitter, receiver and the analog circuitry allows.

Maximum bps is determined experimentally. The data is viewed using hyperterminal, so a lower rate is better. Once further parts of the system are operating we can increase the download capabilities. The physical part of the project has to be done in two phases the testing phase and the finished project. When fin ished the injection circuitry will be added into the fusilage of the plane, and the extraction circuitry will be o n the ground.

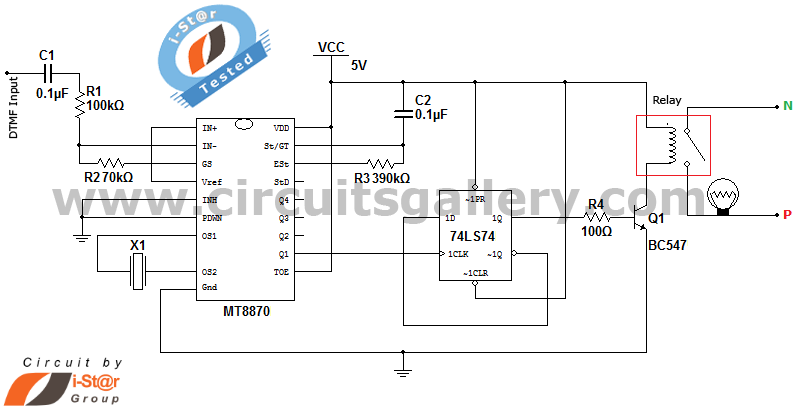

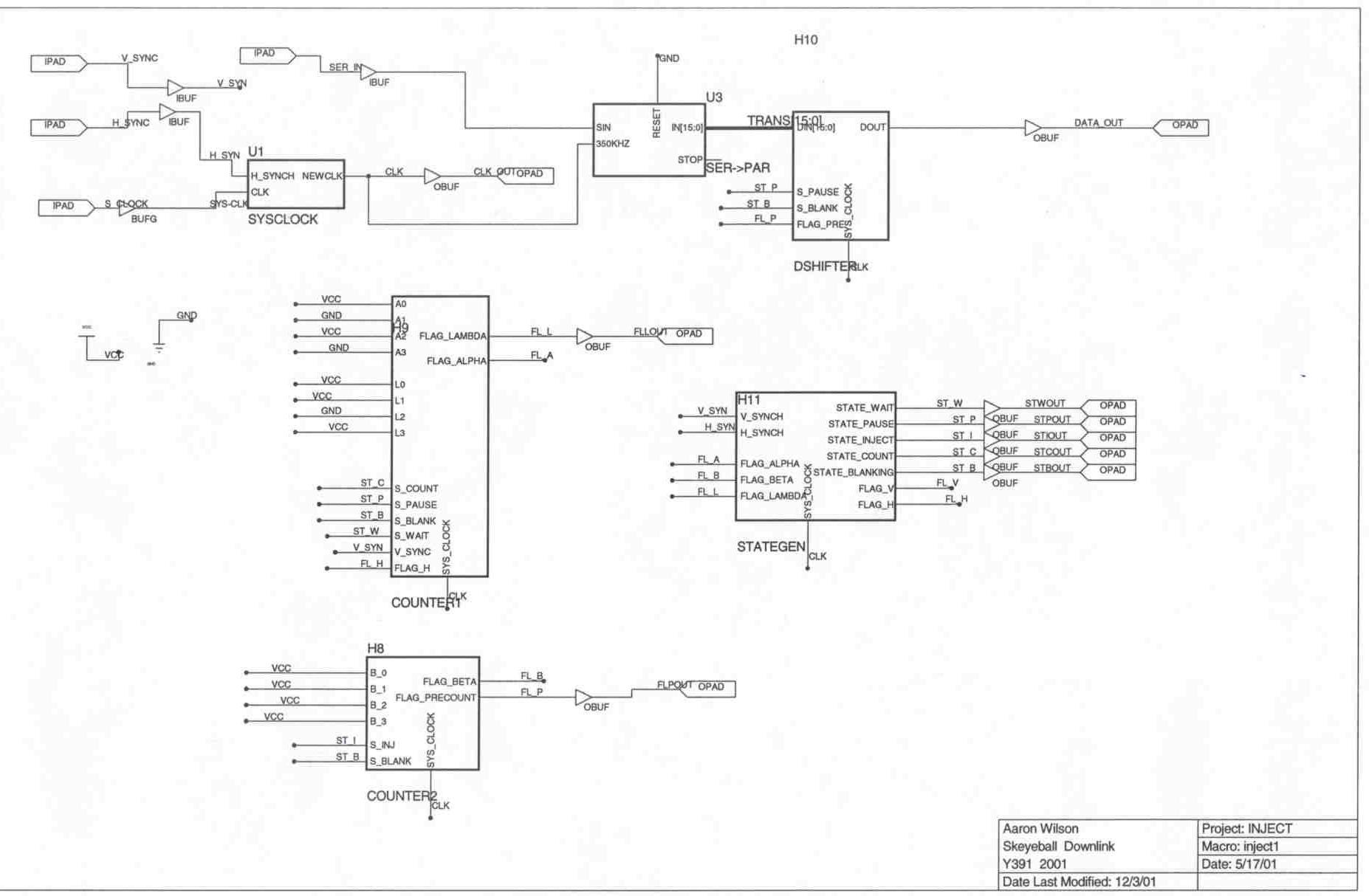

This diagram illustrates how the fit in to the bigger picture. The injection circuitry will communicate with the tracking component via a serial link. It is currently setup to recieve at 9600bps, which can be increased in the future. The transmitter and receiver are dealing with the video signal which has the data in it. On the ground side, after the data is extracted, it can be displayed through hyperterminal, or any other serial interface. and the video can be observed on a monitor. For the testing phase I setup the equipment on two Logic Engines. These provided a good foundation to work off of because the have the structure to do wire wrapping and the slots for the neccesary pins.

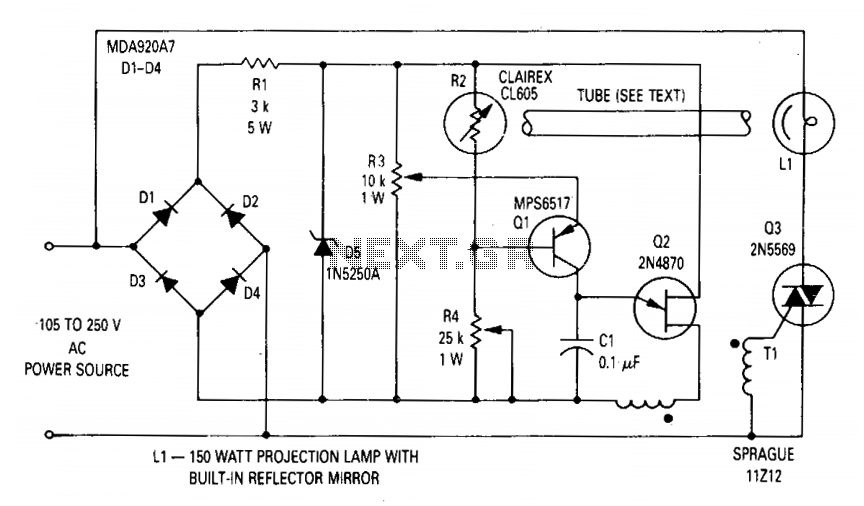

I used the MC1489 and MC1488 chips on the board to send out and recieve the serial communication since they are wired to the serial cables. The analog portion was designed by Bryce Himebaugh and implemented on a bread board with individual resistors, capacitors, and transistors, so that refinements could easily be made on it.

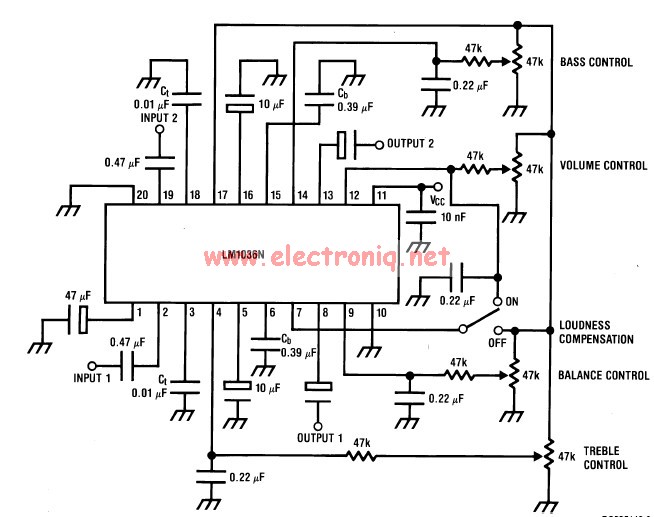

After a few changes to the resistance and capacitance, the analog portion was behaving as expected. This portion is given the video signal and then using a signal synch separator sends the vertical and horizontal synch pulses to the digital portion, it then receives the data back during the correct pulses in the vertical retrace. The digital portion is implemented on the Xilinx 4010 chip. This chip allows ample room for the design, as well as plenty of pins for design usage and testing. The clock is provided by the MX045 chip which gives a 20 MHz pulse which is then divided down to produce the desired data pulse rate.

The design takes as input the vertical and horizontal synch pulses from the analog portion of the design. It counts these pulses in order to know when to output the data in the correct spaces. I followed closely to the same design from previous project, and I used macro 🔗 External reference

The Skeyeball project integrates several key components and methodologies to facilitate effective data transfer from an aircraft to the ground. The system architecture includes a combination of analog and digital circuitry, with a focus on optimizing bandwidth for data transmission. The analog circuits are responsible for handling the NTSC video signal, ensuring that data is injected and extracted during non-visible periods of the video frame. The use of Xilinx FPGA technology allows for flexibility and scalability in the digital processing of the signals, accommodating future enhancements in data rates and functionality.

The implementation of the MC1489 and MC1488 chips for serial communication ensures reliable data transfer between the airborne and ground systems. The careful design of the analog section on a breadboard enables iterative testing and refinement, which is crucial for achieving the desired performance levels. The integration of the MX045 clock generator facilitates accurate timing for data transmission, while the Xilinx 4010 chip's capability to process sync pulses enhances the system's efficiency in data handling.

Overall, the Skeyeball project exemplifies a comprehensive approach to embedded system design, combining theoretical knowledge with practical application to achieve a functional and efficient data downlink system. This project not only serves educational purposes for students involved but also contributes to advancements in embedded systems and RF communication technologies.The Skeyeball project is an ongoing project in the Indiana University System Design Methods Laboratory for both graduate and undergraduate students to perform embedded system design and implement various projects. The downlink portion of the project involves transfering data from the plane to the ground by using a single signal.

My downlink p roject involves re-implementing Prashant Patel`s project from thesummer of 2000, then compacting and debugging it to achieve the desired operation. The first step is to implement the xilinx code using two Logic Engine Boards to host the plane and ground implementation seperately so that adequate testing with the RF transmitter and receiver can be accomplished.

I also re-implemented the analog injection and extraction ciruits with new designs to increase bandwidth. A NTSC signal is generated by the video source and it`s horizontal and vertical synchronizing pulses allow data to be injected at spaces in the signal where the video signal is retracing to the top of the screen and is always black.

The data can be injected in these spots and then extracted from the same spot by the same manner. Once the data is extracted, the video signal is set back to black so that there are no side effects in the video image displayed on the monitor. There are 10 of these spaces in each field and a maximum bandwidth of 300 bits per space. The present goal is an established 56kbps downlink, which is around 90 bits per space. The limitation to higher bps is the bandwidth the RF transmitter, receiver and the analog circuitry allows.

Maximum bps is determined experimentally. The data is viewed using hyperterminal, so a lower rate is better. Once further parts of the system are operating we can increase the download capabilities. The physical part of the project has to be done in two phases the testing phase and the finished project. When fin ished the injection circuitry will be added into the fusilage of the plane, and the extraction circuitry will be o n the ground.

This diagram illustrates how the fit in to the bigger picture. The injection circuitry will communicate with the tracking component via a serial link. It is currently setup to recieve at 9600bps, which can be increased in the future. The transmitter and receiver are dealing with the video signal which has the data in it. On the ground side, after the data is extracted, it can be displayed through hyperterminal, or any other serial interface. and the video can be observed on a monitor. For the testing phase I setup the equipment on two Logic Engines. These provided a good foundation to work off of because the have the structure to do wire wrapping and the slots for the neccesary pins.

I used the MC1489 and MC1488 chips on the board to send out and recieve the serial communication since they are wired to the serial cables. The analog portion was designed by Bryce Himebaugh and implemented on a bread board with individual resistors, capacitors, and transistors, so that refinements could easily be made on it.

After a few changes to the resistance and capacitance, the analog portion was behaving as expected. This portion is given the video signal and then using a signal synch separator sends the vertical and horizontal synch pulses to the digital portion, it then receives the data back during the correct pulses in the vertical retrace. The digital portion is implemented on the Xilinx 4010 chip. This chip allows ample room for the design, as well as plenty of pins for design usage and testing. The clock is provided by the MX045 chip which gives a 20 MHz pulse which is then divided down to produce the desired data pulse rate.

The design takes as input the vertical and horizontal synch pulses from the analog portion of the design. It counts these pulses in order to know when to output the data in the correct spaces. I followed closely to the same design from previous project, and I used macro 🔗 External reference