Early VDO Tachometer Guts

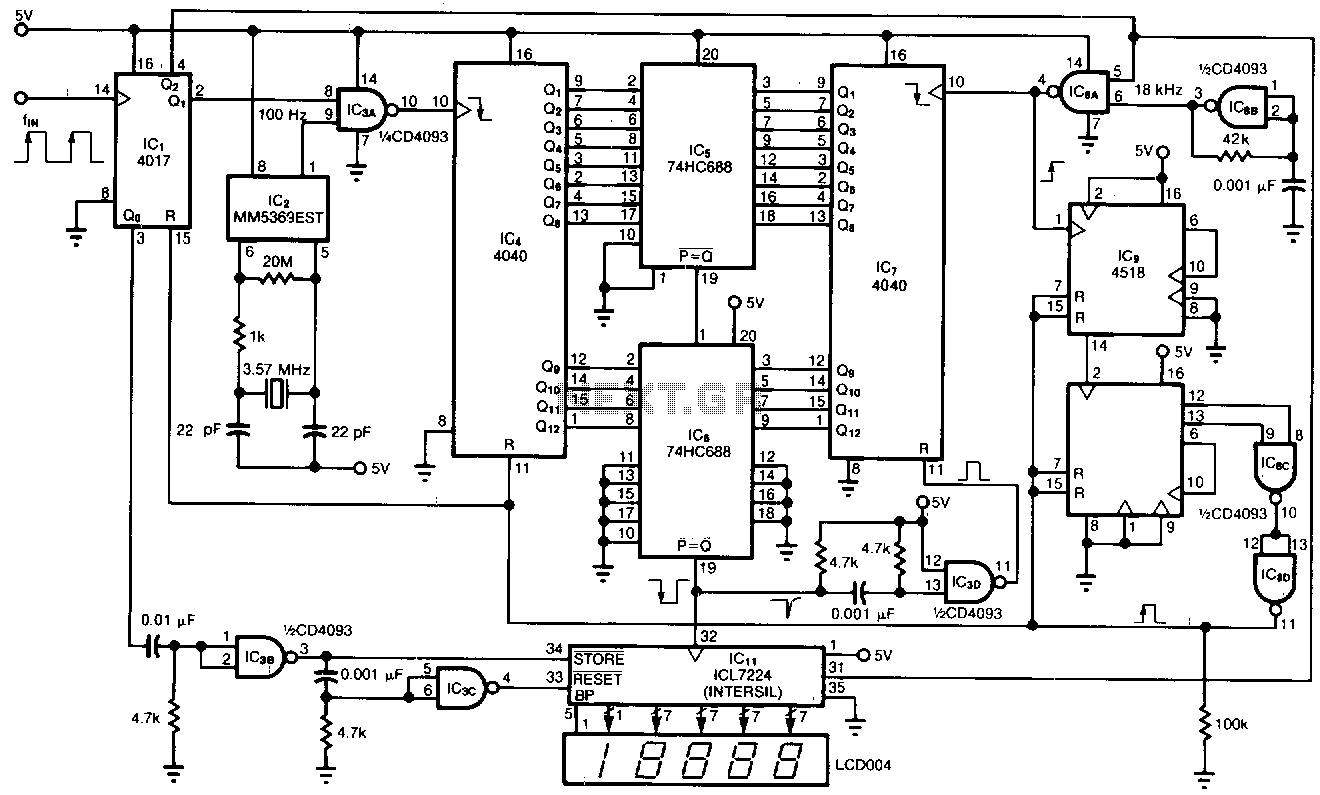

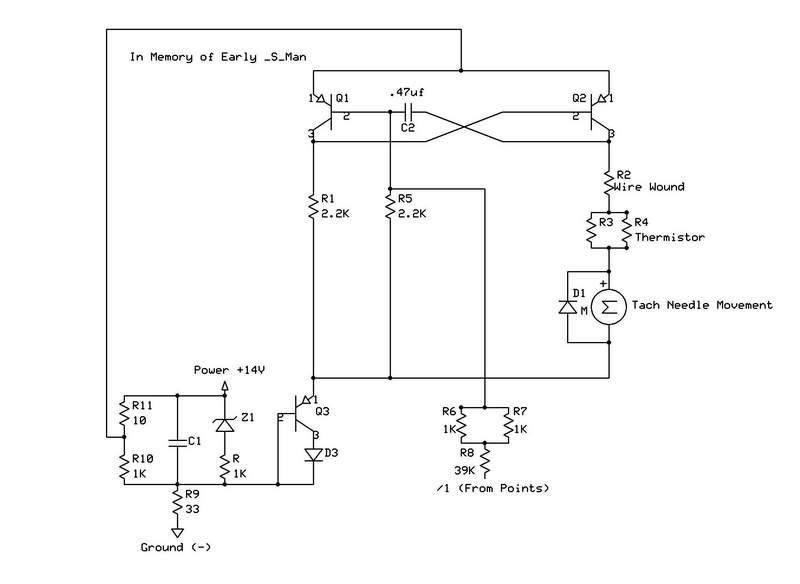

The "crossed-flags" topology of a monostable multivibrator is utilized in a 912 tachometer circuit. Resistor R5, which sets the discharge rate of capacitor C2, differs from that used in a 911 tachometer. The 912 configuration operates at a 50% duty cycle, correlating to four ignition events per complete distributor rotation, with 45 degrees of dwell time per event. In contrast, the 911 model requires a 63% mark time, where the points are closed for 38 out of 60 degrees. When the vehicle is operational, a +14V supply is present at the voltage regulator circuit located at the lower left of the schematic. A Zener diode, with an unspecified breakdown voltage, regulates the voltage on the upper rail, while a capacitor connected in parallel helps smooth out voltage fluctuations caused by the alternator, which are not mitigated by the vehicle's battery. Both transistors Q1 and Q2 are connected to the emitter of Q3, referred to as "ground" in this context, through 2.2K resistors. Due to slight variances in the circuit, one transistor may turn on before the other, but this does not affect functionality. If Q1 saturates first, its base connects to ground via R5, causing its collector to rise above ground potential. This positive voltage at Q1's collector keeps Q2 turned off. When a positive pulse is received at the /1 terminal from the ignition points, it passes through resistors R8 and R6/R7 (which are wired in parallel) to the base of Q1, turning it off. Eventually, as C2 charges fully, current ceases to flow, leading the base of Q1 to drop to ground through the 2.2K resistor. C2 then discharges through a wire-wound resistor, which serves as a calibration element, in parallel with a resistor and thermistor, causing a momentary deflection of the meter needle and completing the circuit via R5.

The circuit functions as a monostable multivibrator, generating a single output pulse in response to an input trigger. The design incorporates a voltage regulator to ensure stable operation, particularly in the presence of voltage ripples from the alternator. The Zener diode plays a crucial role in voltage regulation, preventing over-voltage conditions that could damage sensitive components.

The timing characteristics of the circuit are influenced by the values of the resistors and capacitors. R5, which determines the discharge rate of C2, is critical in defining the pulse width output. The interaction between the capacitors, resistors, and transistors ensures that the output pulse width is proportional to the input frequency, which is essential for accurate tachometer readings.

The configuration of the transistors is such that Q1 acts as the primary switch, while Q2 serves to maintain the state of Q1 under certain conditions. The careful selection of component values is necessary to achieve the desired duty cycle and response time.

In practical applications, variations in component tolerances can lead to differences in performance, which may necessitate calibration or adjustment to achieve optimal operation. The circuit's design allows for flexibility in component selection, enabling adaptation for different vehicle models, such as the 911 and 912 tachometers.

Simulation tools like LTSpice can be used to analyze the circuit's behavior, although users may encounter challenges in achieving the expected output waveforms. Proper setup of the simulation parameters and understanding of the circuit's operation are essential for successful modeling. This circuit exemplifies the integration of analog components to create a reliable measurement system in automotive applications.The "crossed-flags" topology of a monostable multivibrator. Also, this particular board happened to be a 912 tach, so R5, which determines the discharge rate of C2,would be different for a 911. 912`s have a 50% duty cycle (four cylinders, 45 degrees of dwell or MARK time per ignition event- that`s 180 degrees total or 50% of 360 degrees of distributor rotation- another

way to think about it is in 360 degrees of distributor rotation there are four ignition events or 90 degrees per event, of which the points are closed and distributor output is HIGH for 45 degrees or 50% of that) For a 911 you want a 63% MARK time, the points are closed 38 out of 60 degrees. With the car running +14V present on the voltage regulator circuit at the lower left. The Zener (value unknown at this point) has a breakdown voltage of a certain amount which limits the voltage on the top rail and the capacitor wired in parallel smooths out variations in voltage (ripple from the alternator that`s not damped out by the ship`s battery) Both the base of Q1 and Q2 are connected to the emitter of Q3 (I`m going to call this "ground" in the discussion below) through 2.

2K resistors but slight variances in the circuit mean one of them turns on first, it doesn`t matter. Suppose Q1 saturates first, its base is connected to ground through R5. Its collector gets pulled up above ground to positive voltage. This positive voltage is connected to the base of Q2, holding Q2 OFF. Next, a positive pulse arrives at the /1 terminal from the points. This goes through R8 and R6/R7 wired in parallel to the base of Q1, turning it OFF (thanks Loren for the clarification). Eventually C2 is fully charged and no more current flows, so the base of Q1 drops to ground through the 2.

2K resistor and C2 acts like a battery and discharges through the wire wound resistor (the number of turns of wire is a calibration element), resistor and thermistor in parallel and the meter movement, blipping the needle, completing the circuit through R5. I THINK this is right, but am open to corrections or suggestions. I have a model of this circuit in SWCAD III, a free circuit simulator, if anyone wants to try it, send me a PM.

( I can`t make it work, even though the circuit checks OK, I don`t have enough training with circuit simulators). Rick, I actually have been working with LTSpice, still don`t have all the bugs worked out. I get the circuit to check fine with netlist, and the operating points all have voltages- but for some reason I don`t get the nice square wave you do, I get a strange looking current pulse I(Rmeter), the blue trace, measured at the "meter.

" You used a 1V pulsed input as voltage control for the "switch", shown as V(points_d), the green trace, but it doesn`t matter if you use 100V (like Loren said above)- same waveform. BTW there is no "switch" model in LTSpice, thank heaven for the Internet where you can find out how to define a model on the diagram.

Cool! It was also a big help, I didnt` know how to define the transient analysis parameters, but I just copied them from your screen capture until I got it to work. Ditto the "switch. " Rick, I actually have been working with LTSpice, still don`t have all the bugs worked out. I get the circuit to check fine with netlist, and the operating points all have voltages- but for some reason I don`t get the nice square wave you do, I get a strange looking current pulse I(Rmeter), the blue trace, measured at the "meter.

" There must be something wrong in the area of the power supply also. I think that Q1, the Zener and the resistors are supposed to supply a constant voltage across the monostable so that the average value of the const pulse width signal is linearly proportional to the frequency. Does 🔗 External reference

The circuit functions as a monostable multivibrator, generating a single output pulse in response to an input trigger. The design incorporates a voltage regulator to ensure stable operation, particularly in the presence of voltage ripples from the alternator. The Zener diode plays a crucial role in voltage regulation, preventing over-voltage conditions that could damage sensitive components.

The timing characteristics of the circuit are influenced by the values of the resistors and capacitors. R5, which determines the discharge rate of C2, is critical in defining the pulse width output. The interaction between the capacitors, resistors, and transistors ensures that the output pulse width is proportional to the input frequency, which is essential for accurate tachometer readings.

The configuration of the transistors is such that Q1 acts as the primary switch, while Q2 serves to maintain the state of Q1 under certain conditions. The careful selection of component values is necessary to achieve the desired duty cycle and response time.

In practical applications, variations in component tolerances can lead to differences in performance, which may necessitate calibration or adjustment to achieve optimal operation. The circuit's design allows for flexibility in component selection, enabling adaptation for different vehicle models, such as the 911 and 912 tachometers.

Simulation tools like LTSpice can be used to analyze the circuit's behavior, although users may encounter challenges in achieving the expected output waveforms. Proper setup of the simulation parameters and understanding of the circuit's operation are essential for successful modeling. This circuit exemplifies the integration of analog components to create a reliable measurement system in automotive applications.The "crossed-flags" topology of a monostable multivibrator. Also, this particular board happened to be a 912 tach, so R5, which determines the discharge rate of C2,would be different for a 911. 912`s have a 50% duty cycle (four cylinders, 45 degrees of dwell or MARK time per ignition event- that`s 180 degrees total or 50% of 360 degrees of distributor rotation- another

way to think about it is in 360 degrees of distributor rotation there are four ignition events or 90 degrees per event, of which the points are closed and distributor output is HIGH for 45 degrees or 50% of that) For a 911 you want a 63% MARK time, the points are closed 38 out of 60 degrees. With the car running +14V present on the voltage regulator circuit at the lower left. The Zener (value unknown at this point) has a breakdown voltage of a certain amount which limits the voltage on the top rail and the capacitor wired in parallel smooths out variations in voltage (ripple from the alternator that`s not damped out by the ship`s battery) Both the base of Q1 and Q2 are connected to the emitter of Q3 (I`m going to call this "ground" in the discussion below) through 2.

2K resistors but slight variances in the circuit mean one of them turns on first, it doesn`t matter. Suppose Q1 saturates first, its base is connected to ground through R5. Its collector gets pulled up above ground to positive voltage. This positive voltage is connected to the base of Q2, holding Q2 OFF. Next, a positive pulse arrives at the /1 terminal from the points. This goes through R8 and R6/R7 wired in parallel to the base of Q1, turning it OFF (thanks Loren for the clarification). Eventually C2 is fully charged and no more current flows, so the base of Q1 drops to ground through the 2.

2K resistor and C2 acts like a battery and discharges through the wire wound resistor (the number of turns of wire is a calibration element), resistor and thermistor in parallel and the meter movement, blipping the needle, completing the circuit through R5. I THINK this is right, but am open to corrections or suggestions. I have a model of this circuit in SWCAD III, a free circuit simulator, if anyone wants to try it, send me a PM.

( I can`t make it work, even though the circuit checks OK, I don`t have enough training with circuit simulators). Rick, I actually have been working with LTSpice, still don`t have all the bugs worked out. I get the circuit to check fine with netlist, and the operating points all have voltages- but for some reason I don`t get the nice square wave you do, I get a strange looking current pulse I(Rmeter), the blue trace, measured at the "meter.

" You used a 1V pulsed input as voltage control for the "switch", shown as V(points_d), the green trace, but it doesn`t matter if you use 100V (like Loren said above)- same waveform. BTW there is no "switch" model in LTSpice, thank heaven for the Internet where you can find out how to define a model on the diagram.

Cool! It was also a big help, I didnt` know how to define the transient analysis parameters, but I just copied them from your screen capture until I got it to work. Ditto the "switch. " Rick, I actually have been working with LTSpice, still don`t have all the bugs worked out. I get the circuit to check fine with netlist, and the operating points all have voltages- but for some reason I don`t get the nice square wave you do, I get a strange looking current pulse I(Rmeter), the blue trace, measured at the "meter.

" There must be something wrong in the area of the power supply also. I think that Q1, the Zener and the resistors are supposed to supply a constant voltage across the monostable so that the average value of the const pulse width signal is linearly proportional to the frequency. Does 🔗 External reference