Electronic Locker

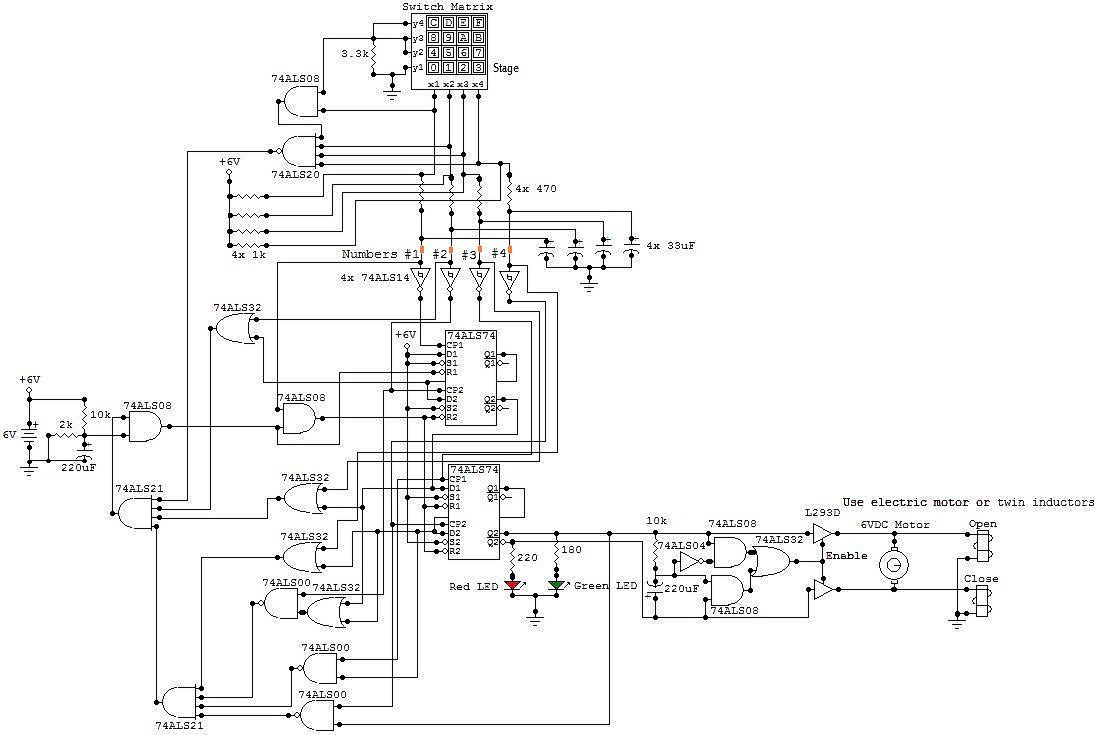

This circuit is an electronic locker controlled by a combination of switches (a code). A switch matrix is mounted on the door of the locker, consisting of 16 switches arranged in four rows and four columns, totaling eight terminals. When a switch is pressed, it establishes contact between its corresponding column and row. This type of switch matrix is also found in telephones, which feature keys numbered from 0 to 9 and from A to F for a total of 16 switches. To unlock the locker, four specific and distinct switches must be pressed in the correct sequence. For instance, if the code is 0, 1, 2, 3, pressing the sequence 0, 1, 2, 2, 3 will not unlock the locker. The code can be set during the circuit's construction. The designated line (referred to as "stage" in the schematic) is connected to ground and to one pin of a 3.3k resistor, while the other line connects to an input of the 7408 and the other pin of the resistor. All the desired code numbers are located on the same line. To establish the order of the code numbers, a proper connection must be made between the node of the 7414 input and the corresponding node of the capacitor. For example, if the first line (y1) is selected and the code is 0, 1, 2, 3, the first number (#1) connects to the top left contact (x1), meaning that switch 0 corresponds to x1/y1. These contact points are highlighted in orange in the schematic. When the locker is locked, a red LED is illuminated, and the green LED is off. Conversely, when the locker is unlocked, the red LED is off, and the green LED is illuminated. To lock the locker, any of the 16 switches on the matrix can be pressed. The locker operates on a 6V power supply, with a recommendation for a 6V rechargeable battery for extended usage (at least three full days), although four 1.5V batteries in series can be used, lasting only five hours but at a lower cost. To conserve energy, the red LED can be omitted. When powered on, the locker remains locked. An electric motor or inductors are employed to secure the door, operating for a short duration before stopping. When unlocking, the motor or inductors open the door for a limited time and then cease operation. For door control, either an electric motor or a pair of inductors can be utilized. If an electric motor is chosen, it rotates counterclockwise for a specified time to lower a toothed bar, then stops, keeping the locker closed. When unlocking, the motor rotates clockwise for a set duration to raise the toothed bar, after which it stops, leaving the locker open. If inductors are used, the second inductor activates for a defined period to move a magnetic bar leftward to lock the locker, then stops. To unlock, the first inductor operates for a certain time to move the magnetic bar rightward, and then it stops. The motor or inductor control buffer (L293D) has two Vcc inputs and four ground connections. Both Vcc inputs must connect to +6V, while all ground connections should link to the circuit's ground. All circuit components are housed in a rack, except for the LEDs and the switch matrix, which are mounted on the door.

The electronic locker circuit is designed for secure access, employing a switch matrix to input a specific code. The matrix consists of 16 switches arranged in a grid, allowing for a combination of inputs to unlock the device. Each switch corresponds to a unique row and column, creating a reliable method for user interaction. The design incorporates logic gates, specifically the 7408, to facilitate the processing of the input signals from the switch matrix. The 7414 is utilized to establish the connections necessary for identifying the correct sequence of switch presses.

The locking mechanism is controlled through a motor or inductors, providing a physical means of securing the locker. The L293D motor driver is essential for managing the power and direction of the motor, ensuring that the locking and unlocking actions are executed smoothly. The choice between using an electric motor or inductors depends on the desired mechanism's efficiency and response time.

Power management is a critical aspect of the design, with considerations made for energy conservation and battery life. The use of a 6V rechargeable battery is recommended for prolonged use, while alternative power sources, such as disposable batteries, are acknowledged for their cost-effectiveness. The inclusion of LEDs serves as visual indicators of the locker's status, enhancing user experience by providing immediate feedback on the locking mechanism's state.

Overall, this electronic locker circuit combines user-friendly design with robust security features, making it suitable for various applications where access control is paramount.This circuit is an Electronic Locker. It is controlled by a switches combination (by a code). There is a switch matrix on the door of the locker. This one is a unit of switches connected into 4 arranged of 4 columns for a total of eight terminals. When we press on a switch, this one establishes the contact between its column and its line. This swi tch matrix is also used in the telephones, for example. But it is numbered from 0 to 9 and from A to F for a total of 16 switches. To open the locker, we have to press 4 specific and different switches in the good order. If for example the code is 0, 1, 2, 3 and we press two times to the same switches: 0, 1, 2, 2, 3 the locker won`t open. In this circuit, the code is 0, 1, 2, 3 but we can set the desired code when we built de circuit. The desired line (called "stage" in the schematic) is connected to the ground and to a pin of the 3. 3k resistor and the other line is connected to an input of the 7408 and to the other pin of the resistor.

All the desired numbers of the code are in the same line. To set the order of the number of the code, we have to set the good connection between the node of the 7414 input and the appropriate node of the capacitor. For example, if we select the first line (y1) and the code is 0, 1, 2, 3 the first number (#1) is connected to the top left contact (x1).

The switch 0 is corresponding to x1/y1. These points of contact are colored in orange in the schematic. When the locker is locked, the red LED is turned on and the green LED is turned off. When the locker is opened, the red LED is turned off and the green LED is turned on. To lock the locker, we can push any of the 16 switches of the matrix. The locker is powered by a 6V source. I recommend using a 6V rechargeable battery because this one lasts a long time (at least 3 full days) and can be re-used. Otherwise, we can use four 1. 5V battery connected in serial. These least only 5 hours but are less expensive. To save energy, we can remove the red LED. When the locker is powered on, it is locked. The electric motor or the inductors close the door while a bit of time and after, stop working. When we open the locker, the electric motor or the inductors open the door while a bit of time and after, stop working.

To control the state of the door (open or lock) we can use an electric motor or a pair of inductors. If we use a electric motor, when the locker is closed, the motor turns in the anti-clockwise direction during a certain time and moves down a toothed bar. After this time, the motor stops turning and the locker remains closed. When the locker is opened, the motor turns in the clockwise direction during a certain time and moves up the toothed bar.

After this time, the motor stops turning and the locker remains opened. If we use two inductors, when the locker is closed, the second inductor works during a certain time and moves left a magnetic bar by attraction. After this time, the inductor stops working and the locker remains closed. When the locker is opened, the first inductor works during a certain time and moves right the magnetic bar.

After this time, the inductor stops turning and the locker remains opened. The buffer (L293D) who controls the motor or the inductors has two Vcc inputs and four ground connections. The both Vcc inputs must be connected to the +6V and all ground connections must be connected to the ground of the circuit.

All the parts of the circuits are placed in the rack except the DELs and the switch matrix which them, are placed on the door. 🔗 External reference

The electronic locker circuit is designed for secure access, employing a switch matrix to input a specific code. The matrix consists of 16 switches arranged in a grid, allowing for a combination of inputs to unlock the device. Each switch corresponds to a unique row and column, creating a reliable method for user interaction. The design incorporates logic gates, specifically the 7408, to facilitate the processing of the input signals from the switch matrix. The 7414 is utilized to establish the connections necessary for identifying the correct sequence of switch presses.

The locking mechanism is controlled through a motor or inductors, providing a physical means of securing the locker. The L293D motor driver is essential for managing the power and direction of the motor, ensuring that the locking and unlocking actions are executed smoothly. The choice between using an electric motor or inductors depends on the desired mechanism's efficiency and response time.

Power management is a critical aspect of the design, with considerations made for energy conservation and battery life. The use of a 6V rechargeable battery is recommended for prolonged use, while alternative power sources, such as disposable batteries, are acknowledged for their cost-effectiveness. The inclusion of LEDs serves as visual indicators of the locker's status, enhancing user experience by providing immediate feedback on the locking mechanism's state.

Overall, this electronic locker circuit combines user-friendly design with robust security features, making it suitable for various applications where access control is paramount.This circuit is an Electronic Locker. It is controlled by a switches combination (by a code). There is a switch matrix on the door of the locker. This one is a unit of switches connected into 4 arranged of 4 columns for a total of eight terminals. When we press on a switch, this one establishes the contact between its column and its line. This swi tch matrix is also used in the telephones, for example. But it is numbered from 0 to 9 and from A to F for a total of 16 switches. To open the locker, we have to press 4 specific and different switches in the good order. If for example the code is 0, 1, 2, 3 and we press two times to the same switches: 0, 1, 2, 2, 3 the locker won`t open. In this circuit, the code is 0, 1, 2, 3 but we can set the desired code when we built de circuit. The desired line (called "stage" in the schematic) is connected to the ground and to a pin of the 3. 3k resistor and the other line is connected to an input of the 7408 and to the other pin of the resistor.

All the desired numbers of the code are in the same line. To set the order of the number of the code, we have to set the good connection between the node of the 7414 input and the appropriate node of the capacitor. For example, if we select the first line (y1) and the code is 0, 1, 2, 3 the first number (#1) is connected to the top left contact (x1).

The switch 0 is corresponding to x1/y1. These points of contact are colored in orange in the schematic. When the locker is locked, the red LED is turned on and the green LED is turned off. When the locker is opened, the red LED is turned off and the green LED is turned on. To lock the locker, we can push any of the 16 switches of the matrix. The locker is powered by a 6V source. I recommend using a 6V rechargeable battery because this one lasts a long time (at least 3 full days) and can be re-used. Otherwise, we can use four 1. 5V battery connected in serial. These least only 5 hours but are less expensive. To save energy, we can remove the red LED. When the locker is powered on, it is locked. The electric motor or the inductors close the door while a bit of time and after, stop working. When we open the locker, the electric motor or the inductors open the door while a bit of time and after, stop working.

To control the state of the door (open or lock) we can use an electric motor or a pair of inductors. If we use a electric motor, when the locker is closed, the motor turns in the anti-clockwise direction during a certain time and moves down a toothed bar. After this time, the motor stops turning and the locker remains closed. When the locker is opened, the motor turns in the clockwise direction during a certain time and moves up the toothed bar.

After this time, the motor stops turning and the locker remains opened. If we use two inductors, when the locker is closed, the second inductor works during a certain time and moves left a magnetic bar by attraction. After this time, the inductor stops working and the locker remains closed. When the locker is opened, the first inductor works during a certain time and moves right the magnetic bar.

After this time, the inductor stops turning and the locker remains opened. The buffer (L293D) who controls the motor or the inductors has two Vcc inputs and four ground connections. The both Vcc inputs must be connected to the +6V and all ground connections must be connected to the ground of the circuit.

All the parts of the circuits are placed in the rack except the DELs and the switch matrix which them, are placed on the door. 🔗 External reference