Electronic pulse circuitry fishing

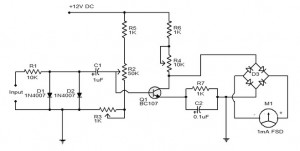

The circuit utilizes the SC3525A, a PWM silicon chip from US General Semiconductor. It features an error amplifier with an inverting input at pin 1. Pin 2 serves as the non-inverting input for the error amplifier. Pins 5 and 6 are designated for timing functions, while pin 7 is the discharge terminal. Pin 8 is used for the soft-start function, and pin 9 is for PWM input compensation. Pin 10 acts as the signal input, pin 11 serves as output A, pin 12 is a side terminal, pin 13 is the output stage bias terminal, pin 14 is output B, pin 15 provides access to the bias voltage terminal, and pin 16 outputs the reference voltage. The internal configuration includes a totem pole amplifier circuit capable of directly driving a power MOSFET.

The SC3525A PWM controller is designed for various applications, including power supplies and motor control circuits, due to its versatility and efficiency. The error amplifier plays a crucial role in maintaining the desired output voltage by comparing the feedback voltage to a reference voltage. The configuration allows for precise control over the output characteristics.

Pins 5 and 6, responsible for timing, determine the frequency and duty cycle of the PWM signal. The timing capacitor and resistors connected to these pins set the oscillation frequency, which is vital for the operation of the circuit. The discharge terminal on pin 7 is essential for resetting the timing capacitor, ensuring that the system can cycle correctly.

The soft-start feature on pin 8 is particularly important in applications where inrush current could damage components. By gradually ramping up the output voltage, this feature protects the circuit during startup.

PWM input compensation on pin 9 allows for adjustments in the PWM signal to optimize performance based on load conditions. The signal input on pin 10 is the primary control input for the PWM signal, which modulates the output based on the desired performance characteristics.

Output A and output B, found on pins 11 and 14 respectively, can drive external components or circuits directly, providing flexibility in design. The bias voltage terminal on pin 15 ensures that the internal circuitry operates within specified voltage levels, while the reference voltage output on pin 16 provides a stable voltage reference for other components in the circuit.

The totem pole output stage enhances the ability of the SC3525A to drive power MOSFETs directly, facilitating efficient switching operations in high-power applications. This characteristic is essential for minimizing losses and improving overall system efficiency. The design of the SC3525A makes it a reliable choice for engineers looking to implement PWM control in their electronic designs.Circuit works: SC3525A for the US General Semiconductor PWM silicon chip, 1 foot of the error amplifier inverting input terminal, pin 2 is the error amplifier non-inverting input terminal, 5,6 feet for the timing of the end, the discharge end 7 feet, 8 feet for soft-start end, 9 feet for the PWM input compensation, 10 feet off the signal input, Il pin as an output a, 12 feet to the side, 13 feet for the output stage bias terminal, 14 feet output B, 15 feet for a bias voltage terminal access, 16 feet for the reference voltage output. Internal manifold with a totem pole amplifier circuit can directly drive the power MOSFET.

The SC3525A PWM controller is designed for various applications, including power supplies and motor control circuits, due to its versatility and efficiency. The error amplifier plays a crucial role in maintaining the desired output voltage by comparing the feedback voltage to a reference voltage. The configuration allows for precise control over the output characteristics.

Pins 5 and 6, responsible for timing, determine the frequency and duty cycle of the PWM signal. The timing capacitor and resistors connected to these pins set the oscillation frequency, which is vital for the operation of the circuit. The discharge terminal on pin 7 is essential for resetting the timing capacitor, ensuring that the system can cycle correctly.

The soft-start feature on pin 8 is particularly important in applications where inrush current could damage components. By gradually ramping up the output voltage, this feature protects the circuit during startup.

PWM input compensation on pin 9 allows for adjustments in the PWM signal to optimize performance based on load conditions. The signal input on pin 10 is the primary control input for the PWM signal, which modulates the output based on the desired performance characteristics.

Output A and output B, found on pins 11 and 14 respectively, can drive external components or circuits directly, providing flexibility in design. The bias voltage terminal on pin 15 ensures that the internal circuitry operates within specified voltage levels, while the reference voltage output on pin 16 provides a stable voltage reference for other components in the circuit.

The totem pole output stage enhances the ability of the SC3525A to drive power MOSFETs directly, facilitating efficient switching operations in high-power applications. This characteristic is essential for minimizing losses and improving overall system efficiency. The design of the SC3525A makes it a reliable choice for engineers looking to implement PWM control in their electronic designs.Circuit works: SC3525A for the US General Semiconductor PWM silicon chip, 1 foot of the error amplifier inverting input terminal, pin 2 is the error amplifier non-inverting input terminal, 5,6 feet for the timing of the end, the discharge end 7 feet, 8 feet for soft-start end, 9 feet for the PWM input compensation, 10 feet off the signal input, Il pin as an output a, 12 feet to the side, 13 feet for the output stage bias terminal, 14 feet output B, 15 feet for a bias voltage terminal access, 16 feet for the reference voltage output. Internal manifold with a totem pole amplifier circuit can directly drive the power MOSFET.