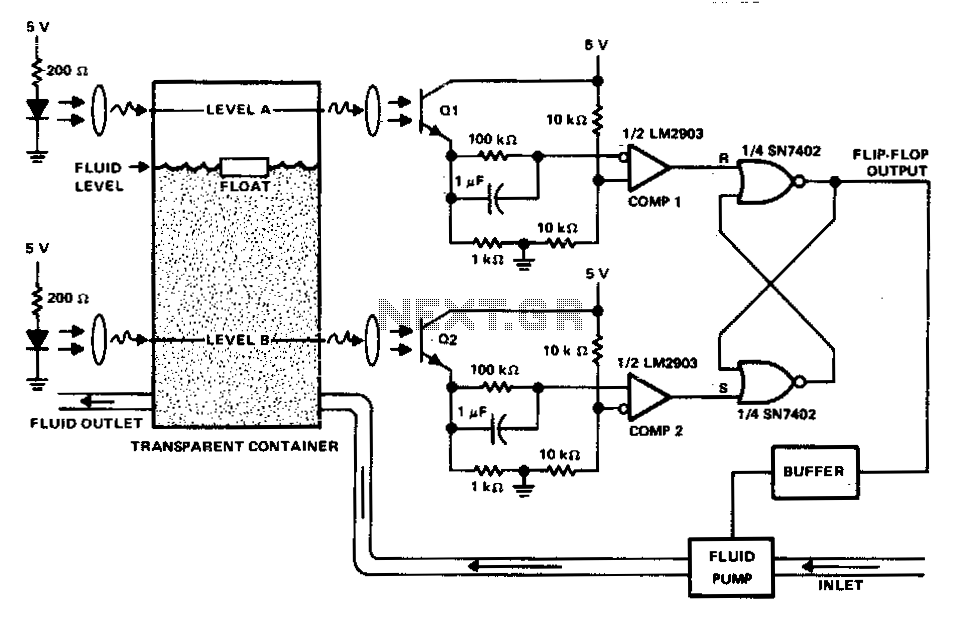

Fluid level controller

This circuit can be used to maintain fluid between two levels. Variations on this control circuit can be made to keep something that moves within certain boundary conditions.

The described circuit functions primarily as a fluid level control system, designed to regulate the fluid levels between two predetermined points. This application is crucial in various industries, such as water treatment, chemical processing, and irrigation systems, where maintaining specific fluid levels is essential for operational efficiency and safety.

At its core, the circuit typically employs a set of sensors, such as float switches or ultrasonic level sensors, to monitor the fluid levels in a tank or reservoir. These sensors provide feedback to a control unit, which processes the information and activates or deactivates pumps or valves accordingly. For instance, when the fluid level falls below a set threshold, the control unit can trigger a pump to fill the tank, while the activation of a valve may be used to drain excess fluid when the level exceeds the upper limit.

In addition to basic fluid level control, variations of this circuit can incorporate additional features such as alarm systems, which alert operators when fluid levels are outside the desired range, or automated control algorithms that optimize fluid management based on consumption rates or other dynamic factors. The design can also include redundancy measures, ensuring that if one sensor fails, another can take over to maintain system integrity.

Overall, the versatility of this control circuit allows it to be adapted for a wide range of applications, providing reliable fluid management solutions in diverse operational environments.This circuit can be used to maintain fluid between two levels Variations on this control circuit can be made to keep something that moves within certain boundary conditions.

The described circuit functions primarily as a fluid level control system, designed to regulate the fluid levels between two predetermined points. This application is crucial in various industries, such as water treatment, chemical processing, and irrigation systems, where maintaining specific fluid levels is essential for operational efficiency and safety.

At its core, the circuit typically employs a set of sensors, such as float switches or ultrasonic level sensors, to monitor the fluid levels in a tank or reservoir. These sensors provide feedback to a control unit, which processes the information and activates or deactivates pumps or valves accordingly. For instance, when the fluid level falls below a set threshold, the control unit can trigger a pump to fill the tank, while the activation of a valve may be used to drain excess fluid when the level exceeds the upper limit.

In addition to basic fluid level control, variations of this circuit can incorporate additional features such as alarm systems, which alert operators when fluid levels are outside the desired range, or automated control algorithms that optimize fluid management based on consumption rates or other dynamic factors. The design can also include redundancy measures, ensuring that if one sensor fails, another can take over to maintain system integrity.

Overall, the versatility of this control circuit allows it to be adapted for a wide range of applications, providing reliable fluid management solutions in diverse operational environments.This circuit can be used to maintain fluid between two levels Variations on this control circuit can be made to keep something that moves within certain boundary conditions.