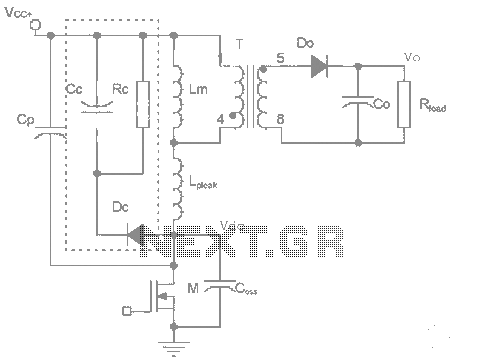

Flyback converter circuit Clamp

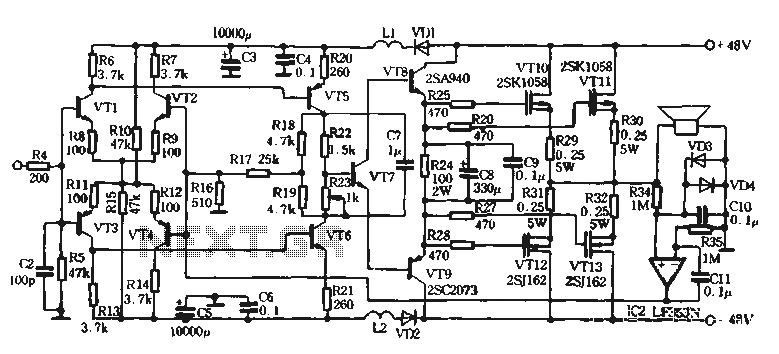

The work process analysis circuit diagram illustrates the use of a flyback converter transformer model. The flyback transformer primarily consists of ideal transformer magnetizing inductance and leakage inductance components. The flyback converter circuit exhibits high-frequency resonance at both ends of the switch, causing the voltage across the switch to increase. However, due to the leakage inductance, energy can be generated and transferred to the capacitor, resulting in the terminal voltage rising from the secondary winding to the maximum voltage (VOR + VSPIKE). When the switch is activated, the capacitor discharges through a resistor, allowing the voltage to recover from (VOR + VSPIKE) back to VOR before the switch is turned off. By appropriately setting the time constants, it is possible to ensure that the release of energy from the leakage inductance to the capacitor is completed within one cycle.

The flyback converter is a type of switched-mode power supply that utilizes a transformer to provide electrical isolation and voltage conversion. The core components of the flyback converter include the transformer, switch (typically a MOSFET), diode, capacitor, and load. The flyback transformer operates in two phases: during the switch's ON state, energy is stored in the transformer's magnetizing inductance; when the switch is turned OFF, the stored energy is transferred to the output through the leakage inductance.

In the circuit diagram, the switch is connected to the primary winding of the transformer. When the switch is closed, current flows through the primary winding, generating a magnetic field and storing energy in the transformer. The voltage across the switch increases due to the high-frequency operation, and the energy stored in the leakage inductance is released to the output capacitor when the switch opens. This process results in a voltage spike (VSPIKE) that adds to the output voltage, leading to a total output voltage of (VOR + VSPIKE).

The capacitor, which is connected to the secondary winding, plays a crucial role in smoothing the output voltage. The resistor in parallel with the capacitor helps to discharge the capacitor, ensuring that the voltage returns to its nominal value (VOR) before the next cycle begins. Proper design of the resistor and capacitor values, along with the selection of a suitable transformer, is essential to optimize the performance of the flyback converter, ensuring that energy is efficiently transferred and that voltage levels remain stable throughout the operation.

In summary, the flyback converter circuit is a sophisticated design that effectively manages energy transfer through careful manipulation of inductance and capacitance, ensuring reliable voltage output while minimizing losses and maximizing efficiency.In the work process analysis circuit diagram, for example, and use of work in flyback converter transformer model. Flyback transformer is mainly composed of ideal transformer magnetizing inductance and leakage inductance components. Figure flyback converter circuit Clamp Leaving the high-frequency resonance occurs at both ends of the switch DS voltage increases, but due to the leakage inductance energy can be generated VSPIKE timely transfer to the CC, leaving the terminal voltage CC rose from the secondary reflector to the maximum voltage VOR (VOR + VSPIKE); when the switch is turned on, CC through the resistor RC discharge tube so that the next cycle before the switch is turned off, the voltage can be made to recover from CC (VOR + VSPIKE) to the VOR. Thus, as long as a reasonable set of time constants, we can guarantee within one cycle will be transferred to CC leakage inductance energy release is completed.

The flyback converter is a type of switched-mode power supply that utilizes a transformer to provide electrical isolation and voltage conversion. The core components of the flyback converter include the transformer, switch (typically a MOSFET), diode, capacitor, and load. The flyback transformer operates in two phases: during the switch's ON state, energy is stored in the transformer's magnetizing inductance; when the switch is turned OFF, the stored energy is transferred to the output through the leakage inductance.

In the circuit diagram, the switch is connected to the primary winding of the transformer. When the switch is closed, current flows through the primary winding, generating a magnetic field and storing energy in the transformer. The voltage across the switch increases due to the high-frequency operation, and the energy stored in the leakage inductance is released to the output capacitor when the switch opens. This process results in a voltage spike (VSPIKE) that adds to the output voltage, leading to a total output voltage of (VOR + VSPIKE).

The capacitor, which is connected to the secondary winding, plays a crucial role in smoothing the output voltage. The resistor in parallel with the capacitor helps to discharge the capacitor, ensuring that the voltage returns to its nominal value (VOR) before the next cycle begins. Proper design of the resistor and capacitor values, along with the selection of a suitable transformer, is essential to optimize the performance of the flyback converter, ensuring that energy is efficiently transferred and that voltage levels remain stable throughout the operation.

In summary, the flyback converter circuit is a sophisticated design that effectively manages energy transfer through careful manipulation of inductance and capacitance, ensuring reliable voltage output while minimizing losses and maximizing efficiency.In the work process analysis circuit diagram, for example, and use of work in flyback converter transformer model. Flyback transformer is mainly composed of ideal transformer magnetizing inductance and leakage inductance components. Figure flyback converter circuit Clamp Leaving the high-frequency resonance occurs at both ends of the switch DS voltage increases, but due to the leakage inductance energy can be generated VSPIKE timely transfer to the CC, leaving the terminal voltage CC rose from the secondary reflector to the maximum voltage VOR (VOR + VSPIKE); when the switch is turned on, CC through the resistor RC discharge tube so that the next cycle before the switch is turned off, the voltage can be made to recover from CC (VOR + VSPIKE) to the VOR. Thus, as long as a reasonable set of time constants, we can guarantee within one cycle will be transferred to CC leakage inductance energy release is completed.