fully automatic emergency light

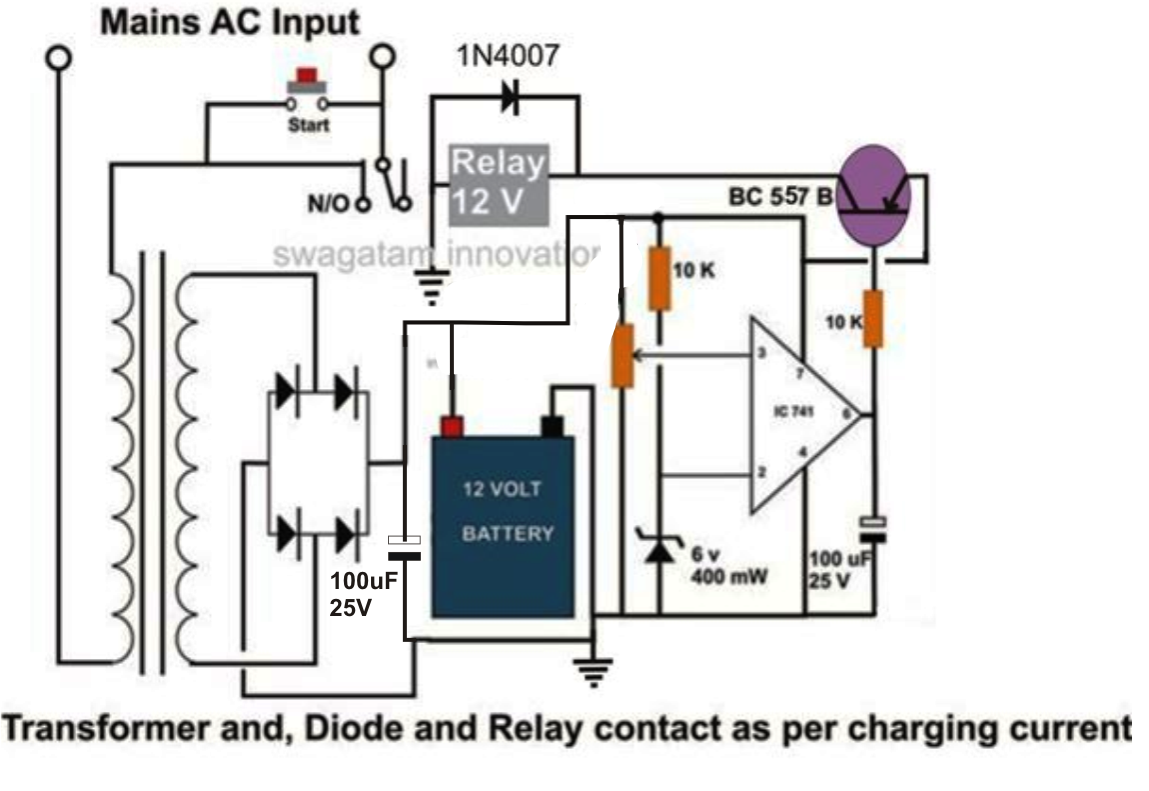

The charging circuit automatically stops when the battery is fully charged, allowing the emergency light to remain connected to the AC mains overnight without concern. The circuit consists of two main sections: the inverter and the charger. The inverter section utilizes the NE555 timer, while the charger section is based on the LM317 adjustable voltage regulator. In the inverter section, the NE555 is configured as an astable multivibrator that generates a 15 kHz square wave. The output from pin 3 of the NE555 is connected to a Darlington pair formed by transistors SL100 (T1) and 2N3055 (T2) through resistor R4. This Darlington pair drives a ferrite transformer (X1) to illuminate a tube light. The inverter transformer X1 is constructed using two EE ferrite cores (25G-13G-8mm size each) with a plastic former. The primary winding consists of 10 turns of 22 SWG wire, while the secondary winding has 500 turns of 34 SWG wire, with insulation between the two windings. To connect the tube light to the ferrite transformer X1, both terminals of each side of the tube light should be shorted before connecting to the secondary of X1. Alternatively, a Darlington pair of BC547 and 2N6292 transistors can be used for a 6W tube light with the same transformer. When mains power is present, reset pin 4 of the NE555 is grounded via transistor T4, preventing the IC from generating a square wave and turning off the emergency light. In the event of a mains failure, transistor T4 does not conduct, allowing pin 4 to receive a positive supply through resistor R3. Consequently, the NE555 begins producing a square wave, and the tube light is activated via transformer X1. In the charger section, the input AC mains is stepped down by transformer X2 to provide 9V-0-9V AC at 500mA. Diodes D1 and D2 rectify the output from the transformer, while capacitors C3 and C4 serve as filters to remove ripple voltage. The unregulated DC voltage is supplied to the LM317 (IC2), where adjusting preset VR1 allows for the output voltage to be set for charging. Once the battery voltage exceeds 6.8V, zener diode ZD1 conducts, causing the regulator IC2 to cease delivering charging voltage. The circuit should be assembled on a general-purpose PCB and housed in a cabinet that provides adequate space for the battery and switches. A 230V AC power plug is required to supply charging voltage to the battery, and a 20W tube outlet should be included in the cabinet for the tube light.

The charging circuit described integrates both an inverter and a charger, functioning effectively to manage battery charging while providing illumination during power outages. The NE555 timer, configured as an astable multivibrator, produces a stable square wave that drives a Darlington pair, enabling efficient operation of the tube light. The transformer design is critical for ensuring proper voltage and current characteristics, with specific winding ratios to achieve the desired output. The inclusion of filtering capacitors enhances the reliability of the power supply by minimizing ripple, thus ensuring that the LM317 regulator can provide a stable charging voltage. The use of a zener diode for voltage regulation prevents overcharging, safeguarding the battery's longevity and performance. Overall, the circuit design emphasizes safety, efficiency, and functionality, making it suitable for emergency lighting applications.The charging circuit stops automatically when the battery is fully charged. So you can leave the emergency light connected to AC mains overnight without any fear. The circuit can be divided into inverter and charger sections. The inverter section is built around timer NE555, while the charger section is built around 3-terminal adjustable regulator LM317. In the inverter section, NE555 is wired as an astable multivibrator that produces a 15kHz squarewave. Output pin 3 of IC 555 is connected to the Darlington pair formed by transistors SL100 (T1) and 2N3055 (T2) via resistor R4.

The Darlington pair drives ferrite transformer X1 to light up the tubelight. For fabricating inverter transformer X1, use two EE ferrite cores (of 25G—13G—8mm size each) along with plastic former. Wind 10 turns of 22 SWG on primary and 500 turns of 34 SWG wire on secondary using some insulation between the primary and secondary.

To connect the tube-light to ferrite transformer X1, first short both terminals of each side of the tube-light and then connect to the secondary of X1. (You can also use a Darlington pair of transistors BC547 and 2N6292 for a 6W tube-light with the same transformer.

) When mains power is available, reset pin 4 of IC 555 is grounded via transistor T4. Thus, IC1 (NE555) does not produce square-wave and emergency light turns off in the presence of mains supply. When mains fails, transistor T4 does not conduct and reset pin 4 gets positive supply though resistor R3.

IC1(NE555) starts producing square wave and tube-light turns on via ferrite transformer X1. In the charger section, input AC mains is stepped down by transformer X2 to deliver 9V-0-9V AC at 500mA. Diodes D1 and D2 rectify the output of the transformer. Capacitors C3 and C4 act as filters to eliminate ripples. The unregulated DC voltage is fed to IC LM317 (IC2). By adjusting preset VR1, the output voltage can be adjusted to deliver the charging voltage. When the battery gets charged above 6. 8V, zener diode ZD1 conducts and regulator IC2 stops delivering the charging voltage. Assemble the circuit on a general-purpose PCB and enclose in a cabinet with enough space for the battery and switches.

Connect a 230V AC power plug to feed charging voltage to the battery and make a 20W tube outlet in the cabinet to switch on the tube-light. Source: 🔗 External reference

The charging circuit described integrates both an inverter and a charger, functioning effectively to manage battery charging while providing illumination during power outages. The NE555 timer, configured as an astable multivibrator, produces a stable square wave that drives a Darlington pair, enabling efficient operation of the tube light. The transformer design is critical for ensuring proper voltage and current characteristics, with specific winding ratios to achieve the desired output. The inclusion of filtering capacitors enhances the reliability of the power supply by minimizing ripple, thus ensuring that the LM317 regulator can provide a stable charging voltage. The use of a zener diode for voltage regulation prevents overcharging, safeguarding the battery's longevity and performance. Overall, the circuit design emphasizes safety, efficiency, and functionality, making it suitable for emergency lighting applications.The charging circuit stops automatically when the battery is fully charged. So you can leave the emergency light connected to AC mains overnight without any fear. The circuit can be divided into inverter and charger sections. The inverter section is built around timer NE555, while the charger section is built around 3-terminal adjustable regulator LM317. In the inverter section, NE555 is wired as an astable multivibrator that produces a 15kHz squarewave. Output pin 3 of IC 555 is connected to the Darlington pair formed by transistors SL100 (T1) and 2N3055 (T2) via resistor R4.

The Darlington pair drives ferrite transformer X1 to light up the tubelight. For fabricating inverter transformer X1, use two EE ferrite cores (of 25G—13G—8mm size each) along with plastic former. Wind 10 turns of 22 SWG on primary and 500 turns of 34 SWG wire on secondary using some insulation between the primary and secondary.

To connect the tube-light to ferrite transformer X1, first short both terminals of each side of the tube-light and then connect to the secondary of X1. (You can also use a Darlington pair of transistors BC547 and 2N6292 for a 6W tube-light with the same transformer.

) When mains power is available, reset pin 4 of IC 555 is grounded via transistor T4. Thus, IC1 (NE555) does not produce square-wave and emergency light turns off in the presence of mains supply. When mains fails, transistor T4 does not conduct and reset pin 4 gets positive supply though resistor R3.

IC1(NE555) starts producing square wave and tube-light turns on via ferrite transformer X1. In the charger section, input AC mains is stepped down by transformer X2 to deliver 9V-0-9V AC at 500mA. Diodes D1 and D2 rectify the output of the transformer. Capacitors C3 and C4 act as filters to eliminate ripples. The unregulated DC voltage is fed to IC LM317 (IC2). By adjusting preset VR1, the output voltage can be adjusted to deliver the charging voltage. When the battery gets charged above 6. 8V, zener diode ZD1 conducts and regulator IC2 stops delivering the charging voltage. Assemble the circuit on a general-purpose PCB and enclose in a cabinet with enough space for the battery and switches.

Connect a 230V AC power plug to feed charging voltage to the battery and make a 20W tube outlet in the cabinet to switch on the tube-light. Source: 🔗 External reference