getting started with sn 6675

To measure temperature without using a thermometer, thermocouples are a viable option. However, thermocouples require a reference temperature, typically 0°C, to determine the temperature difference between the materials of the thermocouples, which can be inconvenient for users. To address this issue, the SN-6675 breakout board has been introduced. This board includes the MAX6675 chip and a bypass capacitor. Specifications include compatibility with K-type thermocouples, a temperature range of 0°C to +1024°C with an output in 0.25-degree increments, and SPI data output that requires three digital I/O pins.

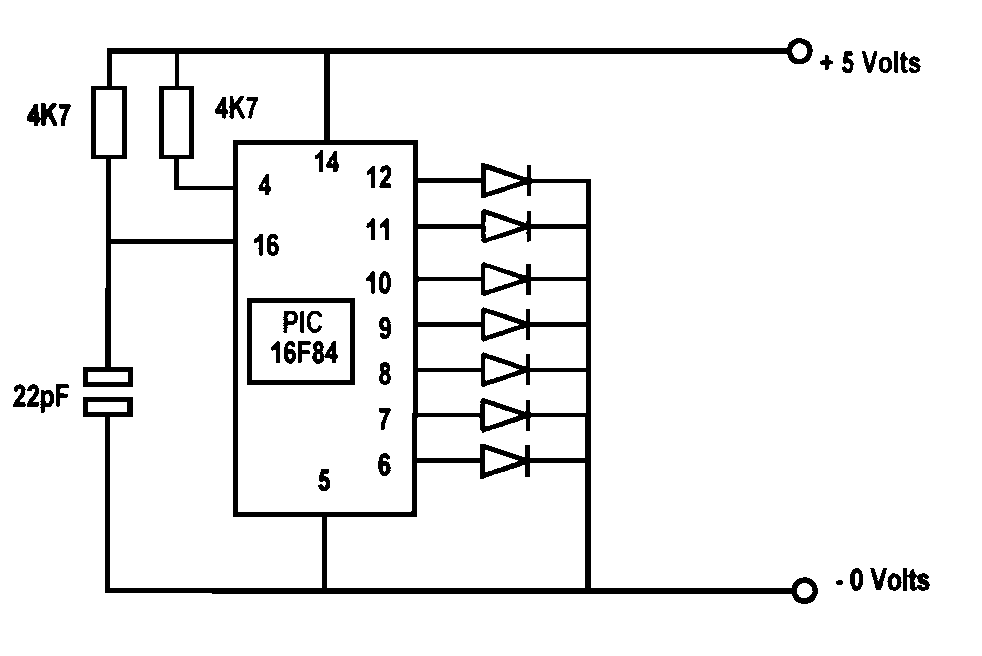

The following outlines part of the sample source code. The microcontroller used in this tutorial is the PIC16F887, with MPlab X version 1.20 and XC8 compiler version 1.0 available for download. For more information, refer to the MPlab X tutorial. The main function is responsible for reading the temperature from the SN-6675. A sub-function detects the 12 bits of data received by the MAX6675 by shifting the bits 16 times before sending it back to the PIC16F887. The code demonstrates a virtual SPI function that generates a clock pulse 16 times to receive the data in 16 bits. This sub-function, which utilizes the virtual SPI function, can be found in the MAX6675 library.

The SN-6675 breakout board is an efficient solution for temperature measurement, utilizing the MAX6675 thermocouple-to-digital converter. This device is designed to work specifically with K-type thermocouples, providing a temperature measurement range from 0°C to +1024°C. The output resolution of 0.25 degrees ensures high precision in temperature readings, making it suitable for various applications.

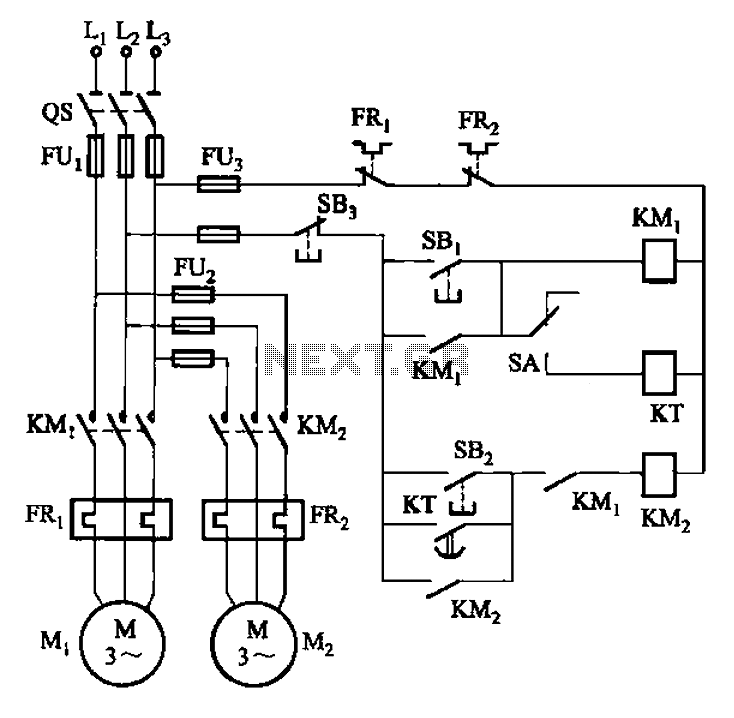

The SPI (Serial Peripheral Interface) communication protocol is employed to facilitate data transfer between the SN-6675 and the microcontroller, in this case, the PIC16F887. The SPI interface requires three digital I/O pins: one for the clock signal, one for the data output from the SN-6675, and one for the chip select signal to activate the MAX6675. The communication process is initiated by the microcontroller generating a clock signal, which synchronizes the data transfer.

The MAX6675 chip processes the temperature data by converting the analog signals from the thermocouple into a digital format. It outputs the temperature data in a 12-bit format, which is then read by the microcontroller. The sub-function responsible for data reception utilizes bit-shifting techniques to correctly align the incoming data for processing. The virtual SPI function is critical in this process, generating the necessary clock pulses to ensure the data is received accurately.

This setup allows for seamless integration of temperature measurement capabilities into various electronic projects, enabling users to monitor temperature with minimal complexity. The SN-6675 breakout board, along with the provided sample code, serves as an excellent starting point for developers looking to implement thermocouple-based temperature sensing in their designs.In order to measure the temperature without using the thermometer, thermocouples are the option to do so. However, the thermocouples need a reference temperature(normally take 0°C ) as to detect the difference of the temperature in between the materials of the thermocouples and is very inconvenience for the user to use it.

Hence, SN-6675 is introduced to do everything for you.This SN-6675 breakout board comes along with MAX6675 and a bypass capacitor. Specification: Works with K type thermocouple 0°C to +1024C output in 0.25 degree increments Internal temperature reading SPI data output requires any 3 digital I/O pins.

The following show some part of the sample source code.. The microcontroller used for this tutorial is PIC16F887. The MPlab X version 1.20 and XC8 compiler version 1.0 can be downloaded from here Please refer here for MPlab X tutorial main function: This function was functioning as to read the temperature from the SN-6675. Sub-function: Since the MAX6675 receive 12 bits of data at once, this function detects the data received by shifting the bits received as much as 16 times before sending it back to PIC16F887.

The following code shows the virtual SPI function generating the clock pulse 16 times in order to receive the data in 16 bits. Sub-function: Since the MAX6675 was received 12 bits of data at once, this function was detected the data received by shifting the bits received as much as 16 times before send it back to main function.

The code following was using the virtual SPI function by generate the clock pulse by 16 times in order to received the data by 16 bits. This sub-function can be found from the MAX6675 library. 🔗 External reference

The following outlines part of the sample source code. The microcontroller used in this tutorial is the PIC16F887, with MPlab X version 1.20 and XC8 compiler version 1.0 available for download. For more information, refer to the MPlab X tutorial. The main function is responsible for reading the temperature from the SN-6675. A sub-function detects the 12 bits of data received by the MAX6675 by shifting the bits 16 times before sending it back to the PIC16F887. The code demonstrates a virtual SPI function that generates a clock pulse 16 times to receive the data in 16 bits. This sub-function, which utilizes the virtual SPI function, can be found in the MAX6675 library.

The SN-6675 breakout board is an efficient solution for temperature measurement, utilizing the MAX6675 thermocouple-to-digital converter. This device is designed to work specifically with K-type thermocouples, providing a temperature measurement range from 0°C to +1024°C. The output resolution of 0.25 degrees ensures high precision in temperature readings, making it suitable for various applications.

The SPI (Serial Peripheral Interface) communication protocol is employed to facilitate data transfer between the SN-6675 and the microcontroller, in this case, the PIC16F887. The SPI interface requires three digital I/O pins: one for the clock signal, one for the data output from the SN-6675, and one for the chip select signal to activate the MAX6675. The communication process is initiated by the microcontroller generating a clock signal, which synchronizes the data transfer.

The MAX6675 chip processes the temperature data by converting the analog signals from the thermocouple into a digital format. It outputs the temperature data in a 12-bit format, which is then read by the microcontroller. The sub-function responsible for data reception utilizes bit-shifting techniques to correctly align the incoming data for processing. The virtual SPI function is critical in this process, generating the necessary clock pulses to ensure the data is received accurately.

This setup allows for seamless integration of temperature measurement capabilities into various electronic projects, enabling users to monitor temperature with minimal complexity. The SN-6675 breakout board, along with the provided sample code, serves as an excellent starting point for developers looking to implement thermocouple-based temperature sensing in their designs.In order to measure the temperature without using the thermometer, thermocouples are the option to do so. However, the thermocouples need a reference temperature(normally take 0°C ) as to detect the difference of the temperature in between the materials of the thermocouples and is very inconvenience for the user to use it.

Hence, SN-6675 is introduced to do everything for you.This SN-6675 breakout board comes along with MAX6675 and a bypass capacitor. Specification: Works with K type thermocouple 0°C to +1024C output in 0.25 degree increments Internal temperature reading SPI data output requires any 3 digital I/O pins.

The following show some part of the sample source code.. The microcontroller used for this tutorial is PIC16F887. The MPlab X version 1.20 and XC8 compiler version 1.0 can be downloaded from here Please refer here for MPlab X tutorial main function: This function was functioning as to read the temperature from the SN-6675. Sub-function: Since the MAX6675 receive 12 bits of data at once, this function detects the data received by shifting the bits received as much as 16 times before sending it back to PIC16F887.

The following code shows the virtual SPI function generating the clock pulse 16 times in order to receive the data in 16 bits. Sub-function: Since the MAX6675 was received 12 bits of data at once, this function was detected the data received by shifting the bits received as much as 16 times before send it back to main function.

The code following was using the virtual SPI function by generate the clock pulse by 16 times in order to received the data by 16 bits. This sub-function can be found from the MAX6675 library. 🔗 External reference