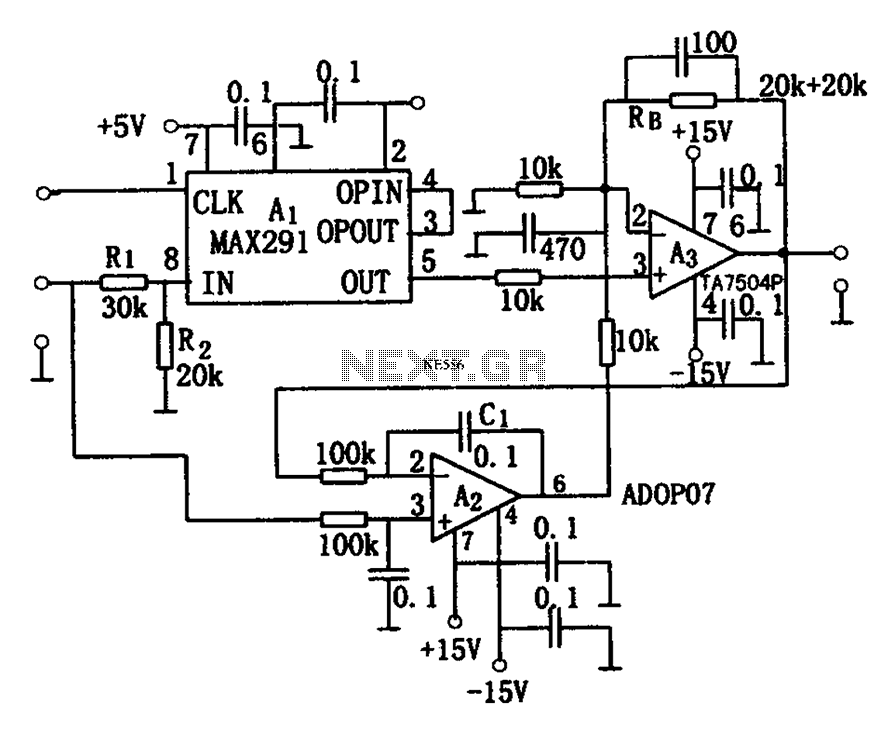

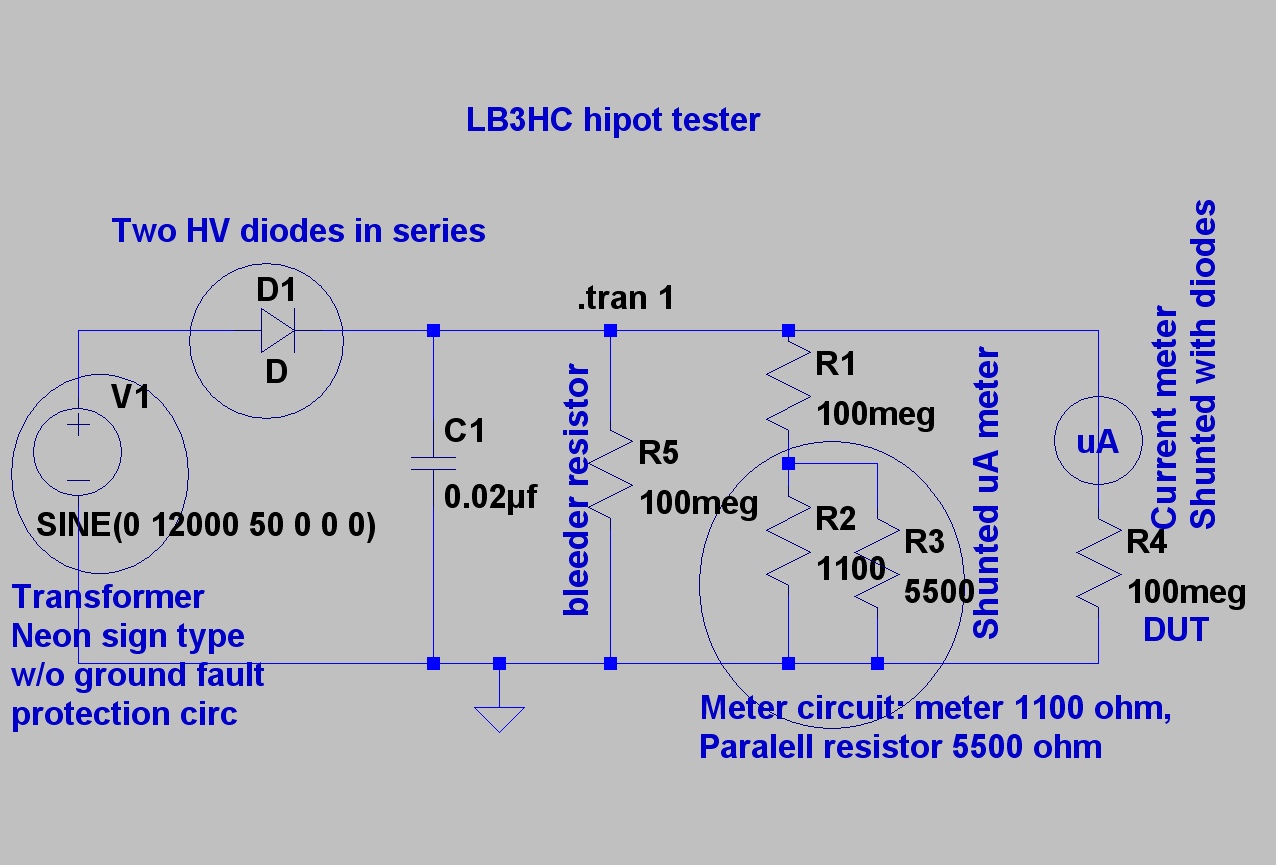

Hi Pot tester schematic

The design is based on concepts from K8CU and AG6K, but the circuit has been simplified and uses different components. The mechanical encapsulation has also been modified. LTspice was utilized to verify the tester prior to construction. The schematic originates from the LTspice simulation. The unit features a 700VA 12kV AC RMS output (nominal) center-tapped neon sign transformer sourced from eBay. This transformer is designed for a primary voltage of less than 230V AC RMS, resulting in an output of slightly over 12kV AC RMS when connected to the 230V AC RMS mains in Norway. After rectification, the output is approximately 17-18kV DC. The transformer is represented by a sine voltage source in LTspice and is insulated from ground for safety. Although the schematic includes a ground connection for compatibility with the Spice 3F4 solver, it is advisable to keep the tester insulated from ground during construction. A variac (not depicted in the schematic) is positioned before the transformer, and the input is current-limited by two 100W light bulbs in parallel (bulbs not shown in the schematic). The voltage measurement circuit consists of a microamp meter with a shunt resistor, while the current measurement uses a standard 100µA instrument safeguarded by back-to-back diodes (not illustrated in the schematic). Since these instruments operate at high potential, it is crucial to implement adequate protection to prevent electrical arcs towards the operator. The device under test (DUT) is included in the schematic. It is important to note that a functioning tube has a significantly higher resistance than the 100 megohms simulated load, which is primarily for testing the output voltage smoothing. The chassis is constructed from plastic and lexan, ensuring long creepage distances through the use of vertical lexan insulators. No creepage currents have been detected at full DC high voltage potential with the current design. A WARNING is issued: building this high voltage device should only be attempted by individuals experienced in electronics and high voltage circuits, as contact with the high voltage leads can be fatal. No responsibility is accepted for the use of this device, and the schematic does not provide a complete circuit description.

The circuit design employs a center-tapped neon sign transformer capable of delivering high voltage outputs, which necessitates careful consideration of safety protocols. The transformer functions by converting low voltage AC input into high voltage AC output, which is then rectified to DC using appropriate rectification components. The rectification stage typically involves high-voltage diodes rated for the output voltage to ensure reliability and safety.

The inclusion of a variac allows for adjustable input voltage, providing control over the output voltage levels. The use of two 100W light bulbs in parallel serves as a current-limiting feature, which helps to protect the circuit from excessive current draw during operation. This is particularly important in high voltage applications where overcurrent can lead to component failure or create hazardous situations.

The voltage measurement setup, which includes a microamp meter and shunt resistor, is designed to provide accurate voltage readings at high potentials. Similarly, the current measurement circuit, utilizing a 100µA instrument with protective diodes, is crucial for monitoring the current flowing through the circuit without exposing the operator to dangerous voltages.

The design emphasizes insulation and creepage distance to mitigate risks associated with high voltage. The use of lexan and other insulating materials contributes to a safer operating environment. It is critical that all components are rated for the high voltage levels present in the circuit to prevent breakdown and ensure longevity.

In summary, this high voltage circuit design integrates several protective measures and features to ensure safe operation while providing high voltage outputs for testing purposes. Proper understanding and adherence to safety guidelines are essential for anyone attempting to replicate or work with this circuit.The design is based loosely on some ideas from K8CU and AG6K. However, I have simplified the circuit somewhat and used different components. The mechanical encapsulation is also different. I used LTspice to verify the tester before building it. The schematic is from the LTspice simulation (see below). I have also posted the simulation files so you can load them into your own LTspice simulator. The unit consists of a 700VA 12KV AC RMS output (nominal) center tapped neon sign transformer that I purchased on Ebay. The trafo was designed for less than 230V AC RMS nominal primary voltage. Therefore the transformer gives out a bit more than 12KV AC RMS when supplied from the 230V AC RMS mains in Norway.

After the rectifier I get approx 17-18 KV DC. The transformer is simulated by a sine voltage source in LTSpice. The transformer is insulated from ground in the tester for safety reasons. The schematic shows a gnd connection but that is only to get the Spice 3F4 solver to accept the netlist. It is recommended to insulate your tester from ground if you build one. There is a variac (not drawn on the schematic) in front of the transformer and the input is current limited by two 100W light bulbs in parallel (bulbs not drawn on the schematic).

The voltage metering circuit is a uA meter with a shunt resistor and the current measurement instrument is a std. 100uA instrument protected by back to back diodes (not drawn on the schematic). The instruments are at high potential so adequate protection must be implemented to prevent arcs to the operator.

The device under test (DUT) is drawn. Note that a working tube has much higher resistance than 100 megs that is the load in the simulation. However this is placed as a load test for the simulation to check smoothing of the output voltage. The chassis is built in plastic and lexan and I have ensured long creepage distances by utilisation of vertical lexan insulators.

There are no detected creepage currents at all even at full DC HV potential with my current design. WARNING: do not attempt to build this high voltage device unless you are experienced in electronics and high voltage circuits. Touching the HV leads may instantly kill you. I do not accept any responsibility for your use of this device. The schematic is not a complete circuit description. 🔗 External reference

The circuit design employs a center-tapped neon sign transformer capable of delivering high voltage outputs, which necessitates careful consideration of safety protocols. The transformer functions by converting low voltage AC input into high voltage AC output, which is then rectified to DC using appropriate rectification components. The rectification stage typically involves high-voltage diodes rated for the output voltage to ensure reliability and safety.

The inclusion of a variac allows for adjustable input voltage, providing control over the output voltage levels. The use of two 100W light bulbs in parallel serves as a current-limiting feature, which helps to protect the circuit from excessive current draw during operation. This is particularly important in high voltage applications where overcurrent can lead to component failure or create hazardous situations.

The voltage measurement setup, which includes a microamp meter and shunt resistor, is designed to provide accurate voltage readings at high potentials. Similarly, the current measurement circuit, utilizing a 100µA instrument with protective diodes, is crucial for monitoring the current flowing through the circuit without exposing the operator to dangerous voltages.

The design emphasizes insulation and creepage distance to mitigate risks associated with high voltage. The use of lexan and other insulating materials contributes to a safer operating environment. It is critical that all components are rated for the high voltage levels present in the circuit to prevent breakdown and ensure longevity.

In summary, this high voltage circuit design integrates several protective measures and features to ensure safe operation while providing high voltage outputs for testing purposes. Proper understanding and adherence to safety guidelines are essential for anyone attempting to replicate or work with this circuit.The design is based loosely on some ideas from K8CU and AG6K. However, I have simplified the circuit somewhat and used different components. The mechanical encapsulation is also different. I used LTspice to verify the tester before building it. The schematic is from the LTspice simulation (see below). I have also posted the simulation files so you can load them into your own LTspice simulator. The unit consists of a 700VA 12KV AC RMS output (nominal) center tapped neon sign transformer that I purchased on Ebay. The trafo was designed for less than 230V AC RMS nominal primary voltage. Therefore the transformer gives out a bit more than 12KV AC RMS when supplied from the 230V AC RMS mains in Norway.

After the rectifier I get approx 17-18 KV DC. The transformer is simulated by a sine voltage source in LTSpice. The transformer is insulated from ground in the tester for safety reasons. The schematic shows a gnd connection but that is only to get the Spice 3F4 solver to accept the netlist. It is recommended to insulate your tester from ground if you build one. There is a variac (not drawn on the schematic) in front of the transformer and the input is current limited by two 100W light bulbs in parallel (bulbs not drawn on the schematic).

The voltage metering circuit is a uA meter with a shunt resistor and the current measurement instrument is a std. 100uA instrument protected by back to back diodes (not drawn on the schematic). The instruments are at high potential so adequate protection must be implemented to prevent arcs to the operator.

The device under test (DUT) is drawn. Note that a working tube has much higher resistance than 100 megs that is the load in the simulation. However this is placed as a load test for the simulation to check smoothing of the output voltage. The chassis is built in plastic and lexan and I have ensured long creepage distances by utilisation of vertical lexan insulators.

There are no detected creepage currents at all even at full DC HV potential with my current design. WARNING: do not attempt to build this high voltage device unless you are experienced in electronics and high voltage circuits. Touching the HV leads may instantly kill you. I do not accept any responsibility for your use of this device. The schematic is not a complete circuit description. 🔗 External reference