Homebuilt Hellschreibers

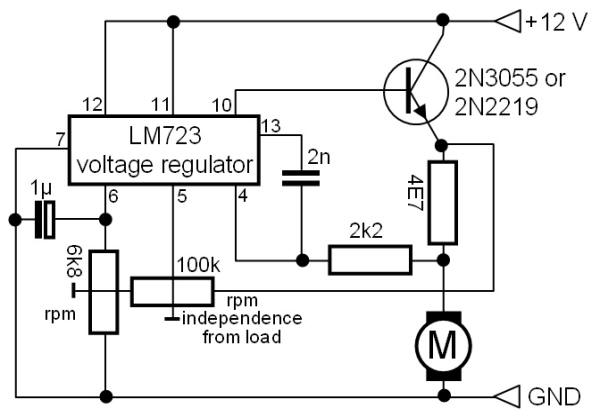

The circuitry for the tone detector, solenoid driver, and motor speed control (for paper transport and spindle) is relatively simple. A solid-state implementation of the driver circuit typically requires a diode (installed in reverse polarity) across the magnet solenoid to prevent damage from the inductive voltage spike that occurs when de-energizing the solenoid. This component is known as a flyback, snubber, freewheeling, catch, or suppressor diode. If the relay operates slowly when energized, it may be possible to enhance its speed using one of the simple circuits described. These circuits briefly apply nearly double the supply voltage to the relay coil during energization. The capacitor in the circuit must be adjusted according to the desired speed and relay decay time. Calibrating the paper transport speed is straightforward; a stopwatch and a ruler or tape measure are all that is needed. The motor RPM should be adjusted to achieve approximately 47 cm per minute. Unlike the spindle in a Feld-Hell machine, the spindle in this setup is a single-thread (1-start) worm that must rotate at 7 columns per character x 2.5 characters per second x 60 seconds/minute = 1050 RPM. The Feld-Hell machine features a double-thread (2-start) spindle with two intertwined windings. It is important to note that the number of threads does not correlate with the number of turns of each thread; both the Feld-Hell and this custom-built spindle consist of two turns. The Feld-Hell spindle only needs to rotate at half the speed of the single-thread spindle, or 525 RPM, to achieve the same effect. There are several methods to adjust the spindle speed to 1050 RPM: 1) ensure the electromagnet functions properly, then feed the printer with verified Hell audio and adjust the RPM until the print is legible and the text lines are horizontal; or 2) use a tachometer. Method two involves constructing a simple optical sensor using four inexpensive components, attaching a strobe disk to the spindle shaft with adhesive, and measuring the sensor output signal with an oscilloscope. A crude strobe card can be created with a black felt marker, though it is recommended to print one on regular paper using a laser printer for better reflectivity. The sensor consists of an infrared LED and a phototransistor, with no specific types required (an IR diode and transistor in a single package, such as the SY-CR102, may also be used). The components were shielded with shrink tubing (black for the 5 mm LED and blue for the 3 mm phototransistor). The leads were bent to ensure that the diode and transistor are not parallel but are positioned approximately 2-3 cm apart. The greatest output swing from the sensor (5 Vpp) was recorded at a distance of 0.8-1 cm from the strobe disk. The scope image indicated that the spindle was turning at 1500 RPM and required adjustment. A period of 10 msec (100 Hz) equates to 100 cycles per second, and with four black segments on the strobe card, this results in 100/4=25 rps, which translates to 25x60=1500 RPM. The oscilloscope was set to AC coupling. The ink roller consists of several round felt pads that were stacked, glued together, and drilled through the center. These pads are typically felt bumper feet for furniture, available in various forms at local DIY stores. An alternative option includes using a felt polishing wheel or tip from a Dremel-type rotary tool.

The described circuitry integrates multiple components for efficient operation. The tone detector is designed to identify specific audio frequencies, which triggers the solenoid driver circuit. The solenoid driver utilizes a solid-state relay for reliable switching, while the flyback diode safeguards against voltage spikes, ensuring the longevity of the components.

For motor speed control, a feedback loop is implemented, allowing real-time adjustments based on the output from the optical sensor. The sensor's infrared LED and phototransistor work in tandem to detect the rotation speed of the spindle, providing valuable data for the control system. The adjustment mechanism for the spindle speed, which can be achieved through various methods, emphasizes the importance of precision in applications where print quality is critical.

The calibration process for the paper transport speed is straightforward, requiring minimal tools and effort. The use of a tachometer or an optical sensor simplifies the task of achieving the desired speed, ensuring accurate and consistent operation. The choice of materials for the ink roller, such as felt pads, reflects a practical approach to component selection, ensuring effective ink application during operation.

In summary, the described electronic circuitry is designed for efficient control of a tone detection and printing system, integrating various components for optimal performance. The methods for calibration and adjustment ensure that the system operates within specified parameters, resulting in high-quality output.The circuitry for the tone detector, solenoid driver, and motor speed control (paper transport and spindle) is rather straightforward. A solid-state implementation of the driver circuit typically needs a diode (installed with reversed polarity) across the magnet solenoid, to avoid damage due to the inductive voltage spike upon de-energizing the solenoid.

This is referred to as a flyback, snubber, freewheeling, catch, or suppressor diode. If the relay is a bit slow when energized, you may try to speed it up with one of the simple circuits described here. They basically briefly apply almost twice the supply voltage to the relay coil when energizing. The capacitor in the circuit will have to be adapted to the desired speed and relay (decay time). Paper transport speed calibration is easy: all you need is a stopwatch and a ruler or tape measure. Simply adjust the motor rpm to obtain about 47 cm per minute. Unlike the spindle in a Feld-Hell machine, my spindle is a single-thread (1-start) worm. It needs to turn at 7 columns per character x 2 ½ characters per sec x 60 sec/min = 1050 rpm. The Feld-Hell machine has a double-thread (2-start) spindle: it has two intertwined windings. Note that the number of threads is not related to the number of turns of each thread! Both the Feld-Hell and my homebuilt spindle have two turns. The Feld-Hell spindle only needs to turn at ½ x 1050 = 525 rpm, to get the same effect as a single-thread spindle at 1050 rpm.

Adjusting the spindle speed to 1050 rpm can be done several ways: 1) first get the electro-magnet to work properly (which you have to do anyway, hi), then feed the printer with "known-good" Hell-audio and adjust the rpm until the print becomes legible and the text lines are horizontal; or 2) use a tachometer. I used method nr. 2 by building a very simple optical sensor (4 cheap components), attaching a strobe disk to the spindle shaft with a dab of glue, and measuring the sensor output signal with an oscilloscope.

You can make a crude strobe card with a black felt marker, but such markers are really not black at all, and the ink does not have good reflectivity. Best is to print one on regular paper with a laser printer. Here is a file with strobe disks that have 1, 2, and 4 black segments and ±5 cm (2") diameter. The sensor simply consists of an infrared LED and a phototransistor. No specific types (you can also use an IR diode + transistor in a single package, e. g. , an SY-CR102). I shielded them with shrink tube (black on the 5 mm LED, blue on the 3 mm phototransistor in the photo below).

As you can see in the photo, I bent the leads such that the diode and transistor are not parallel, but are trained at a point just in front of them (about 2-3 cm, 1"). The largest swing in the sensor output signal (5 Vpp) was observed at a distance of 0. 8-1 cm ( ±3/8") from the strobe disk. The scope image below indicates that the spindle is turning at 1500 rpm, and needs adjustment. A period of 10 msec (100 Hz) = 100 cycles per second, and 4 black segments on the strobe card means 100/4=25 rps which is 25x60=1500 rpm.

The scope is set to AC-coupling. The ink-roller is made of several round felt pads that I stacked, glued together, and drilled a hole through the center. The pads are simply felt bumper-feet for furniture (the ones with adhesive backing are the easiest), available in several forms at your local Do It Yourself store.

An other option is a felt polishing wheel (or tip) from a Dremel ® type rotar 🔗 External reference

The described circuitry integrates multiple components for efficient operation. The tone detector is designed to identify specific audio frequencies, which triggers the solenoid driver circuit. The solenoid driver utilizes a solid-state relay for reliable switching, while the flyback diode safeguards against voltage spikes, ensuring the longevity of the components.

For motor speed control, a feedback loop is implemented, allowing real-time adjustments based on the output from the optical sensor. The sensor's infrared LED and phototransistor work in tandem to detect the rotation speed of the spindle, providing valuable data for the control system. The adjustment mechanism for the spindle speed, which can be achieved through various methods, emphasizes the importance of precision in applications where print quality is critical.

The calibration process for the paper transport speed is straightforward, requiring minimal tools and effort. The use of a tachometer or an optical sensor simplifies the task of achieving the desired speed, ensuring accurate and consistent operation. The choice of materials for the ink roller, such as felt pads, reflects a practical approach to component selection, ensuring effective ink application during operation.

In summary, the described electronic circuitry is designed for efficient control of a tone detection and printing system, integrating various components for optimal performance. The methods for calibration and adjustment ensure that the system operates within specified parameters, resulting in high-quality output.The circuitry for the tone detector, solenoid driver, and motor speed control (paper transport and spindle) is rather straightforward. A solid-state implementation of the driver circuit typically needs a diode (installed with reversed polarity) across the magnet solenoid, to avoid damage due to the inductive voltage spike upon de-energizing the solenoid.

This is referred to as a flyback, snubber, freewheeling, catch, or suppressor diode. If the relay is a bit slow when energized, you may try to speed it up with one of the simple circuits described here. They basically briefly apply almost twice the supply voltage to the relay coil when energizing. The capacitor in the circuit will have to be adapted to the desired speed and relay (decay time). Paper transport speed calibration is easy: all you need is a stopwatch and a ruler or tape measure. Simply adjust the motor rpm to obtain about 47 cm per minute. Unlike the spindle in a Feld-Hell machine, my spindle is a single-thread (1-start) worm. It needs to turn at 7 columns per character x 2 ½ characters per sec x 60 sec/min = 1050 rpm. The Feld-Hell machine has a double-thread (2-start) spindle: it has two intertwined windings. Note that the number of threads is not related to the number of turns of each thread! Both the Feld-Hell and my homebuilt spindle have two turns. The Feld-Hell spindle only needs to turn at ½ x 1050 = 525 rpm, to get the same effect as a single-thread spindle at 1050 rpm.

Adjusting the spindle speed to 1050 rpm can be done several ways: 1) first get the electro-magnet to work properly (which you have to do anyway, hi), then feed the printer with "known-good" Hell-audio and adjust the rpm until the print becomes legible and the text lines are horizontal; or 2) use a tachometer. I used method nr. 2 by building a very simple optical sensor (4 cheap components), attaching a strobe disk to the spindle shaft with a dab of glue, and measuring the sensor output signal with an oscilloscope.

You can make a crude strobe card with a black felt marker, but such markers are really not black at all, and the ink does not have good reflectivity. Best is to print one on regular paper with a laser printer. Here is a file with strobe disks that have 1, 2, and 4 black segments and ±5 cm (2") diameter. The sensor simply consists of an infrared LED and a phototransistor. No specific types (you can also use an IR diode + transistor in a single package, e. g. , an SY-CR102). I shielded them with shrink tube (black on the 5 mm LED, blue on the 3 mm phototransistor in the photo below).

As you can see in the photo, I bent the leads such that the diode and transistor are not parallel, but are trained at a point just in front of them (about 2-3 cm, 1"). The largest swing in the sensor output signal (5 Vpp) was observed at a distance of 0. 8-1 cm ( ±3/8") from the strobe disk. The scope image below indicates that the spindle is turning at 1500 rpm, and needs adjustment. A period of 10 msec (100 Hz) = 100 cycles per second, and 4 black segments on the strobe card means 100/4=25 rps which is 25x60=1500 rpm.

The scope is set to AC-coupling. The ink-roller is made of several round felt pads that I stacked, glued together, and drilled a hole through the center. The pads are simply felt bumper-feet for furniture (the ones with adhesive backing are the easiest), available in several forms at your local Do It Yourself store.

An other option is a felt polishing wheel (or tip) from a Dremel ® type rotar 🔗 External reference