Homemade PC Boards

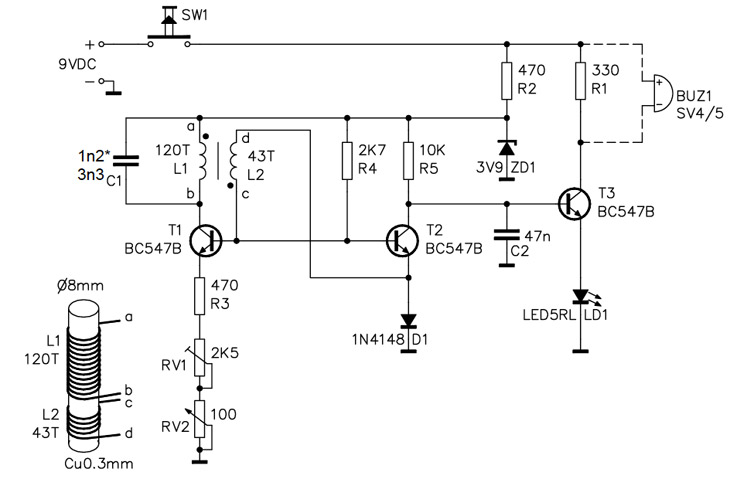

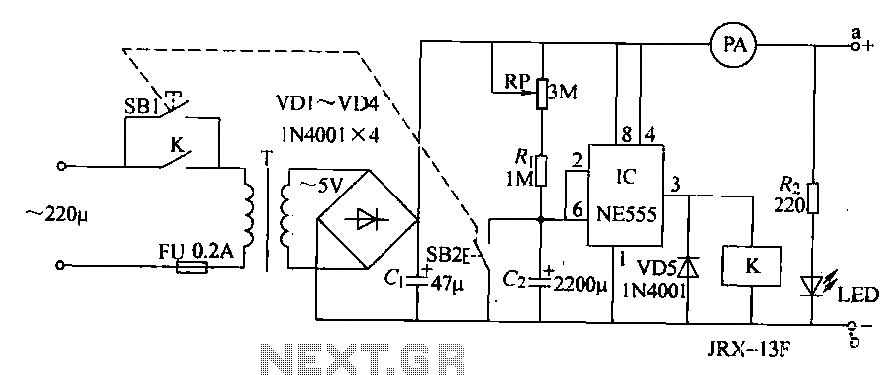

Control the two digits representing minutes; this circuit includes two shift registers, 30 resistors, and 30 LEDs. The schematic illustrates the design. As the circuit design neared completion, it became evident that soldering all components onto a basic prototyping circuit board would be quite laborious. Prototyping boards typically feature a matrix of pads for component placement, but they lack embedded traces for interconnecting components. If pre-printed traces are present, they are often not optimally located. Consequently, research was initiated to design a printed circuit board (PCB) specifically for this circuit. Numerous free software options are available for this purpose, many of which include schematic drafting capabilities and can link PCB design to the schematic, facilitating accurate trace connections to the correct pads. The chosen software was ExpressPCB and ExpressSCH due to its user-friendly interface and the company’s provision of low-cost PCB printing, albeit with a longer wait time. However, the desire for immediate results led to the exploration of home-printing PCBs. Research revealed that the home PCB printing process is simpler and more cost-effective than using professional services, especially for single boards. The method involves creating an etch-resist mask of the circuit design by printing it on glossy paper with a laser printer, then transferring the toner to a blank board using a hot iron. The board is subsequently immersed in an acid solution that removes any uncovered copper. After cleaning the board with acetone to eliminate the toner, a new printed circuit board is obtained. Designing a two-sided board introduced the challenge of aligning both masks during application. By taping the masks together and sandwiching the board, alignment was achieved. However, the first attempt resulted in misalignment due to one image being flipped incorrectly, which was only discovered during the toner removal process.

The circuit is designed to control a two-digit display representing minutes, utilizing two shift registers to manage the data output to the LEDs. Each of the 30 resistors serves to limit current to the corresponding LEDs, ensuring proper brightness and preventing damage. The shift registers facilitate the serial input and parallel output of data, allowing for efficient manipulation of the display digits. The schematic provides a clear representation of the interconnections between the components, illustrating how the shift registers interface with the LEDs and resistors.

The decision to create a custom PCB stems from the limitations of standard prototyping boards, which often do not allow for optimal component arrangement. The utilization of PCB design software simplifies the process of creating a layout that reflects the desired circuit functionality. The chosen software, ExpressPCB and ExpressSCH, not only allows for schematic drafting but also provides an integrated platform for PCB layout, ensuring that all connections are accurately represented.

Home PCB fabrication offers a practical solution for rapid prototyping, particularly for one-off designs. The method of using a laser printer to create an etch-resist mask is both accessible and cost-effective, allowing for the quick turnaround of prototypes. The challenge of aligning masks for a double-sided board requires careful planning and execution, with the potential for error if images are not correctly oriented prior to the transfer process.

Overall, this circuit design exemplifies the integration of digital logic with practical electronic components, demonstrating the ability to create a functional and visually informative display. The detailed approach to both the design and the prototyping process reflects a commitment to achieving a reliable and effective electronic solution.Control the two digits representing minutes; this circuit includes two shift registers, 30 resistors, and 30 LEDs. (All told, a particularly simplecircuit, really. ) Here`s the schematic: As I came closer to completing the circuit design, it occurred to me that trying to solder all of these components on a simple prototyping circuit board would be onerous at best.

(If you`ve ever done this kind of thing before, you know what I`m talking about!) Typically, prototyping boards have a matrix of pads for placing components, but no embedded traces connecting components to each other (or, if they have pre-printed traces, they are usually not in the most useful places). So I began researching designing a printed circuit board specifically for this circuit. There`s a plethora of freeware available to download for this purpose; many packages come with schematic drafting software as well, and are able to link the PCB design to the schematic, which greatly assists with ensuring traces connect the correct pads.

The package I chose was ExpressPCB and ExpressSCH; I like the interface and the company provides low-cost PCB board printing, if you`re willing to wait a little while for them. (For the record, I`m not endorsing their product or their company per se-it works for me, but it may not work for you.

) Then I got restless. I didn`t want to wait the month for ExpressPCB to print and ship my board. I wanted it right now! (I mean, the name of the company is "express, " after all. ) I remembered that a few months ago I had stumbled on a website with some crazy scheme for home-printing PC-boards, using some complex combination of laser printers, acids, and duct tape or something. So I did some additional researching and discovered that printing a PC-board at home is much simpler than I imagined, and significantly cheaper than having a professional shop do it, especially if I was only doing one-off boards.

There are dozens of sites which describe the method (here`s one ). Essentially, you create an etch-resist mask of the printed circuit design by printing it (using a laser printer) on glossy paper, then transferring the laser toner to a blank board using a hot iron. Once the mask is transferred, you drop the board into an acid solution (available at Radio Shack), which eats away any copper not covered by the laser-toner mask.

After some cleaning with acetone to remove the toner from the finished/etched board, you`ve got a shiny new printed circuit board! Of course, not one for doing anything easily, I had to go and design a two-sided board; this adds the complication of having to ensure that both masks are aligned when they are applied.

By lining up the masks face to face and taping them together along one side then sandwiching the board between them, I was able to solve this problem pretty easily. Or so I thought. Turns out, when I made my first board, I managed to flip one of the images in the wrong direction, so they no longer lined up properly.

(I checked all the edges, but never bothered to check the pads themselves, and didn`t discover the mistake until cleaning off the toner. ) 🔗 External reference

The circuit is designed to control a two-digit display representing minutes, utilizing two shift registers to manage the data output to the LEDs. Each of the 30 resistors serves to limit current to the corresponding LEDs, ensuring proper brightness and preventing damage. The shift registers facilitate the serial input and parallel output of data, allowing for efficient manipulation of the display digits. The schematic provides a clear representation of the interconnections between the components, illustrating how the shift registers interface with the LEDs and resistors.

The decision to create a custom PCB stems from the limitations of standard prototyping boards, which often do not allow for optimal component arrangement. The utilization of PCB design software simplifies the process of creating a layout that reflects the desired circuit functionality. The chosen software, ExpressPCB and ExpressSCH, not only allows for schematic drafting but also provides an integrated platform for PCB layout, ensuring that all connections are accurately represented.

Home PCB fabrication offers a practical solution for rapid prototyping, particularly for one-off designs. The method of using a laser printer to create an etch-resist mask is both accessible and cost-effective, allowing for the quick turnaround of prototypes. The challenge of aligning masks for a double-sided board requires careful planning and execution, with the potential for error if images are not correctly oriented prior to the transfer process.

Overall, this circuit design exemplifies the integration of digital logic with practical electronic components, demonstrating the ability to create a functional and visually informative display. The detailed approach to both the design and the prototyping process reflects a commitment to achieving a reliable and effective electronic solution.Control the two digits representing minutes; this circuit includes two shift registers, 30 resistors, and 30 LEDs. (All told, a particularly simplecircuit, really. ) Here`s the schematic: As I came closer to completing the circuit design, it occurred to me that trying to solder all of these components on a simple prototyping circuit board would be onerous at best.

(If you`ve ever done this kind of thing before, you know what I`m talking about!) Typically, prototyping boards have a matrix of pads for placing components, but no embedded traces connecting components to each other (or, if they have pre-printed traces, they are usually not in the most useful places). So I began researching designing a printed circuit board specifically for this circuit. There`s a plethora of freeware available to download for this purpose; many packages come with schematic drafting software as well, and are able to link the PCB design to the schematic, which greatly assists with ensuring traces connect the correct pads.

The package I chose was ExpressPCB and ExpressSCH; I like the interface and the company provides low-cost PCB board printing, if you`re willing to wait a little while for them. (For the record, I`m not endorsing their product or their company per se-it works for me, but it may not work for you.

) Then I got restless. I didn`t want to wait the month for ExpressPCB to print and ship my board. I wanted it right now! (I mean, the name of the company is "express, " after all. ) I remembered that a few months ago I had stumbled on a website with some crazy scheme for home-printing PC-boards, using some complex combination of laser printers, acids, and duct tape or something. So I did some additional researching and discovered that printing a PC-board at home is much simpler than I imagined, and significantly cheaper than having a professional shop do it, especially if I was only doing one-off boards.

There are dozens of sites which describe the method (here`s one ). Essentially, you create an etch-resist mask of the printed circuit design by printing it (using a laser printer) on glossy paper, then transferring the laser toner to a blank board using a hot iron. Once the mask is transferred, you drop the board into an acid solution (available at Radio Shack), which eats away any copper not covered by the laser-toner mask.

After some cleaning with acetone to remove the toner from the finished/etched board, you`ve got a shiny new printed circuit board! Of course, not one for doing anything easily, I had to go and design a two-sided board; this adds the complication of having to ensure that both masks are aligned when they are applied.

By lining up the masks face to face and taping them together along one side then sandwiching the board between them, I was able to solve this problem pretty easily. Or so I thought. Turns out, when I made my first board, I managed to flip one of the images in the wrong direction, so they no longer lined up properly.

(I checked all the edges, but never bothered to check the pads themselves, and didn`t discover the mistake until cleaning off the toner. ) 🔗 External reference