How to connect a pulled motor from a printer to Breadboard and control with raspberry pi

A couple of motors were salvaged from an old printer, and there is uncertainty regarding how to connect them to a breadboard and subsequently to a Raspberry Pi. A cobbler kit for the Raspberry Pi is available for this purpose. Additionally, there is uncertainty about the type of motor, whether it is a DC motor or a stepper motor.

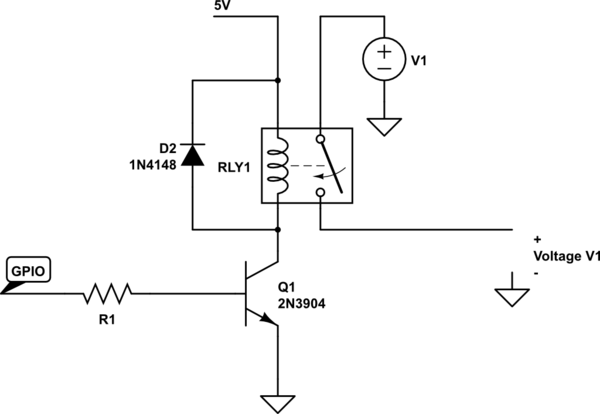

To connect the salvaged motors to a breadboard and interface them with a Raspberry Pi, it is essential to first identify the type of motors. If the motors are DC motors, they will typically have two terminals and can be driven using a simple H-bridge circuit for direction control and PWM (Pulse Width Modulation) for speed control. On the other hand, if the motors are stepper motors, they will have multiple terminals, usually four, six, or eight, depending on the type of stepper motor.

For a DC motor setup, the following components are typically required:

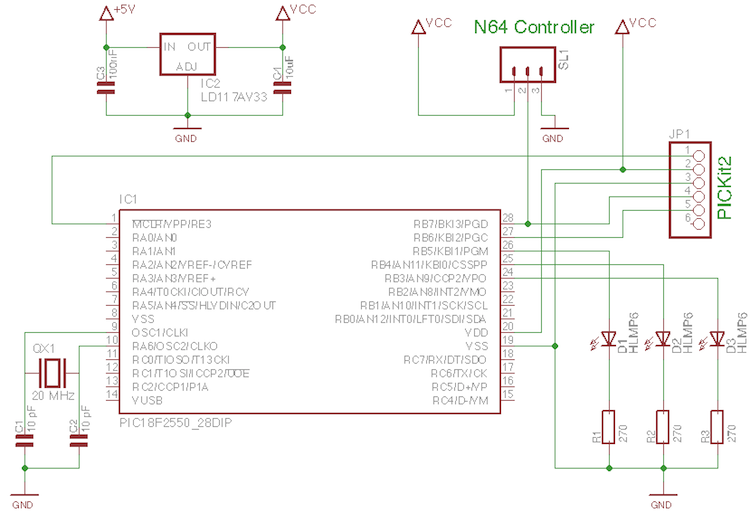

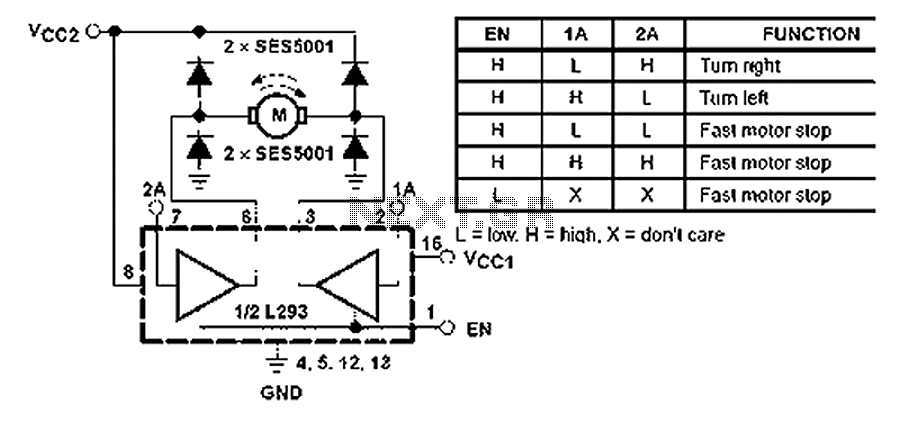

1. H-Bridge Motor Driver: This component allows for the control of the motor's direction and speed. Common H-bridge ICs include the L298N or L293D.

2. Power Supply: Ensure that the power supply voltage matches the motor specifications.

3. Raspberry Pi GPIO Pins: These pins will be used to send control signals to the H-bridge.

4. Breadboard: For easy connections and prototyping.

The connection process involves:

- Connecting the motor terminals to the output pins of the H-bridge.

- Connecting the H-bridge inputs to the Raspberry Pi GPIO pins.

- Providing power to the H-bridge from an appropriate external power source.

- Using the Raspberry Pi's GPIO library to control the motor through the H-bridge.

For a stepper motor setup, a stepper motor driver, such as the A4988 or DRV8825, is recommended. The stepper motor driver will simplify the control of the stepper motor by managing the sequence of signals required to rotate the motor. The connection process includes:

- Connecting the stepper motor wires to the driver according to the motor's wiring configuration.

- Connecting the driver to the Raspberry Pi GPIO pins for step and direction control.

- Providing adequate power to the stepper motor driver from an external power source.

In both cases, it is advisable to consult the datasheets for the specific motors and drivers to ensure proper connections and configurations. Additionally, programming the Raspberry Pi to control the motors can be accomplished using Python with libraries such as RPi.GPIO or gpiozero. This will allow for precise control over motor movements and functionalities.I managed to salvage a couple of motors from a worn down old printer, and I`m unsure of how to get about connecting it to a breadboard and then to a Raspberry Pi. I`ve got a cobbler kit for my Pi that allows me to connect it up to the breadboard. I`m also unsure about what kind of motor it is, DC or Stepper. The motor looks like: 🔗 External reference

To connect the salvaged motors to a breadboard and interface them with a Raspberry Pi, it is essential to first identify the type of motors. If the motors are DC motors, they will typically have two terminals and can be driven using a simple H-bridge circuit for direction control and PWM (Pulse Width Modulation) for speed control. On the other hand, if the motors are stepper motors, they will have multiple terminals, usually four, six, or eight, depending on the type of stepper motor.

For a DC motor setup, the following components are typically required:

1. H-Bridge Motor Driver: This component allows for the control of the motor's direction and speed. Common H-bridge ICs include the L298N or L293D.

2. Power Supply: Ensure that the power supply voltage matches the motor specifications.

3. Raspberry Pi GPIO Pins: These pins will be used to send control signals to the H-bridge.

4. Breadboard: For easy connections and prototyping.

The connection process involves:

- Connecting the motor terminals to the output pins of the H-bridge.

- Connecting the H-bridge inputs to the Raspberry Pi GPIO pins.

- Providing power to the H-bridge from an appropriate external power source.

- Using the Raspberry Pi's GPIO library to control the motor through the H-bridge.

For a stepper motor setup, a stepper motor driver, such as the A4988 or DRV8825, is recommended. The stepper motor driver will simplify the control of the stepper motor by managing the sequence of signals required to rotate the motor. The connection process includes:

- Connecting the stepper motor wires to the driver according to the motor's wiring configuration.

- Connecting the driver to the Raspberry Pi GPIO pins for step and direction control.

- Providing adequate power to the stepper motor driver from an external power source.

In both cases, it is advisable to consult the datasheets for the specific motors and drivers to ensure proper connections and configurations. Additionally, programming the Raspberry Pi to control the motors can be accomplished using Python with libraries such as RPi.GPIO or gpiozero. This will allow for precise control over motor movements and functionalities.I managed to salvage a couple of motors from a worn down old printer, and I`m unsure of how to get about connecting it to a breadboard and then to a Raspberry Pi. I`ve got a cobbler kit for my Pi that allows me to connect it up to the breadboard. I`m also unsure about what kind of motor it is, DC or Stepper. The motor looks like: 🔗 External reference