inverter

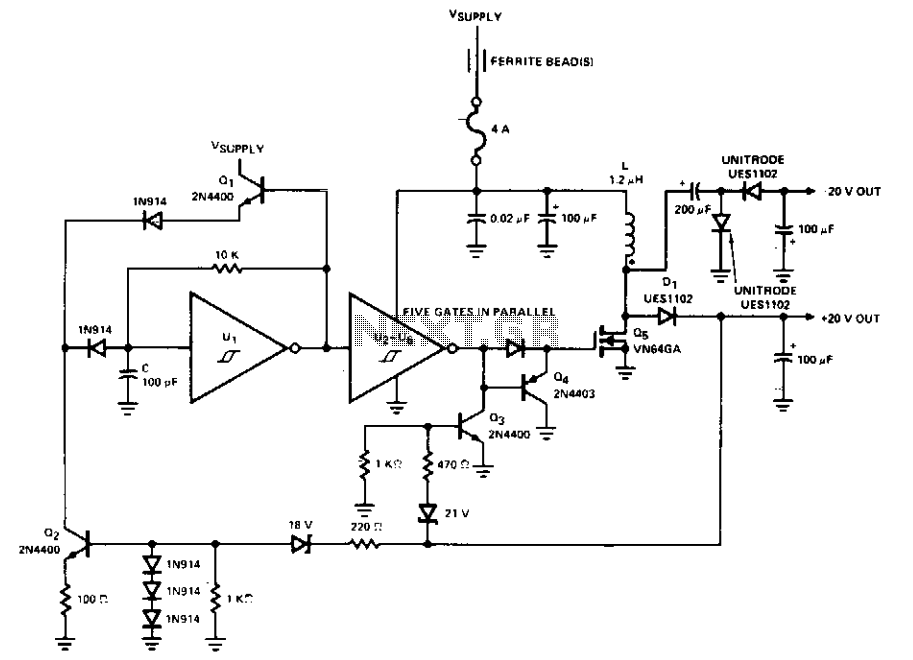

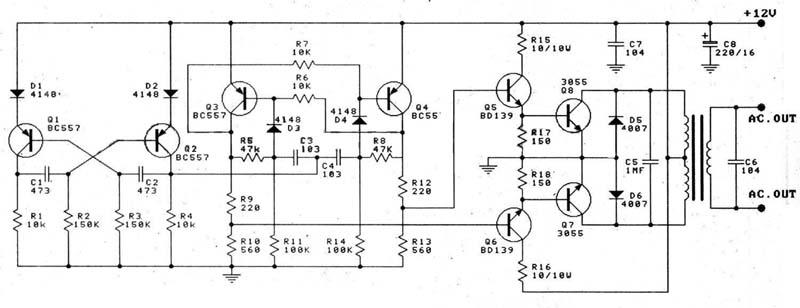

The inverter converts the 12 Volt DC battery voltage into a square wave voltage with a frequency of 50 Hz and a duty cycle of 25%. This voltage is then transformed by transformer Tr1 to 230 Volt RMS. The oscillator is formed by IC1, which operates at 100 Hz (or 120 Hz for a 60 Hz output). The frequency is determined by capacitor C1 and resistors R4 and R5. Resistor R6 influences the flyback time of the oscillator, affecting the frequency and the RMS output voltage, which must be taken into account if the circuit is intended for other frequencies. A frequency of 60 Hz can be achieved through alignment, while higher frequencies necessitate changes in the frequency-determining components. For stable frequency operation, C1 must be chosen carefully; ceramic capacitors are unsuitable due to their temperature sensitivity, whereas most foil capacitors maintain a consistent frequency even under significant temperature variations. IC2 sets the pulse width, thus regulating the RMS output voltage. The regulator comprises transistor T1, which receives input from diodes D4 and D5 connected to the primary transformer coil. The regulator adjusts the output voltage by modifying the pulse width and prevents RMS voltage increases under inductive or capacitive loads. The regulation characteristics can be modified by changing D4, which is particularly important for 24 Volt applications; a lower voltage level for D4 results in "softer" regulation, reducing the proportional factor. Unlike earlier inverter designs, IC8 is now directly controlled by the oscillator signal, eliminating errors caused by unexpected oscillations of PWM-IC2. This arrangement alternates the impulses for both transistor lines, corresponding to the positive and negative halves of the output voltage, resulting in a final frequency of 50 Hz. Flip-flop IC7 retains the switching-off instruction for the current limiter for the remainder of the half wave. Control signals from gates IC5 (4093-III) and IC6 (4093-IV) drive the complementary MOSFET driver stage transistors T5/T6 and T7/T8. T6 and T7 are N-channel enhancement MOSFETs, while T5 and T8 are complementary P-channel enhancement MOSFETs, forming a CMOS basic circuit. Resistors R44 to R47 are included for current limitation during the switching process, providing protection against disturbances. This control unit is designed for inverters with output power up to 10 kW. The driver stage transistors T5 to T8 provide signals to the power MOSFETs, which alternately energize transformer Tr1. Inductive idle currents, such as those from electric motors, can be returned to the battery due to the integrated antiparallel recirculating diodes of the transistors, thus minimizing unnecessary losses compared to earlier inverter designs. The primary function of the inverter is performed by MOSFET transistors T13 to T28, organized into two groups of eight transistors each. These transistors alternately generate the positive and negative halves of the output voltage, with each transistor line operating on its own transformer coil. When a transistor line is turned off, the magnetic energy stored in the transformer’s magnetic field returns to the battery via the integrated recirculation diodes of the other transistor line. The idle current from inductive loads follows the same path. In the event of excessive heating of the transistors, which should only occur due to equipment defects, the bimetal thermal switch F2 disconnects the control electronics. Under normal operating conditions, the heat sink's temperature should remain low enough to be safely touched.

The inverter circuit described operates efficiently by employing a square wave generation technique, which is essential for converting low-voltage DC to higher-voltage AC. The oscillator, utilizing an integrated circuit (IC), is critical in establishing the desired frequency output, which can be adjusted based on the application requirements. The use of resistors and capacitors in conjunction with the oscillator IC allows for precise control over the frequency and duty cycle, ensuring that the output voltage is stable and suitable for various loads.

The regulation mechanism, which includes a transistor and diodes, plays a pivotal role in maintaining the output voltage within acceptable limits, particularly when dealing with varying load conditions. The incorporation of MOSFETs in the design enhances efficiency, as they provide rapid switching capabilities and lower on-resistance compared to traditional transistors, leading to reduced heat generation and improved overall performance.

The design also addresses the challenges associated with inductive loads, which are common in practical applications. The ability to recirculate idle currents back to the battery minimizes energy loss and enhances the system's efficiency. Furthermore, the thermal protection implemented through the bimetal switch ensures that the inverter operates safely under varying conditions, preventing damage from overheating.

In summary, this inverter design is robust, with well-considered components that work together to provide a reliable source of AC power from a DC source, suitable for a wide range of applications, including those with inductive loads. The careful selection of components, along with the thoughtful arrangement of the circuit, contributes to its effectiveness and efficiency, making it a valuable solution in power conversion applications.The inverter chops the 12 Volt DC Battery voltage into a square wave voltage of 50 cycles per second and duty cycle of 25%, transformed by transformer Tr1 to 230 Volt rms. IC1 forms the oscillator with 100 cycles per second (120 cycles per second for 60 cycles output). Frequency is determined by C1 and the resistors R4 and R5. Resistor R6 determin s the time of the flyback of the oscillator and affects likewise the frequency. In addition, R6 affects the rms of the output voltage, which must be considered if necessary, if the circuit shall be used for other frequencies. 60 cycles per second can be achieved by alignment, higher frequencies require changes in the frequency-determining parts.

For high stability of frequency, special attention must be spent on condenser C1. Ceramic capacitors are not usefull, due to their high sensitivity on temperature. Most foil condensers may keep the frequency quite constant, even against strong temperature variations. IC2 determines the pulse width and thus rms of the output voltage. The regulater consists of transistor T1, which receives its signal from the diodes D4 and D5, taken from the primary tranformer coil.

The regulator adjusts the output voltage by changing the pulse width. It prevents also rising of rms on inductive or capacitive load. The characteristics of regulation can be adapted by changing D4 (important on 24 Volts applications!). Lower voltage level of D4 results in "softer" regulation, i. e. an reduction of the proportional factor. Against earlier versions of the inverter, IC 8 now will be switched directly by the oscillator signal, thus avoiding errors by unexpected oscillations of the PWM-IC 2.

Here the alternate allocation of the impulses for both transistor lines, i. e. for the positive and the negative half wave of the output voltage takes place. The final frequency of 50 cycles per second develops. Flip-flop IC7 stores a switching off instruction of the current limiter for the rest of the half wave. From the gates IC5 (4093-III) and IC6 (4093-IV), the control signal arrives at the complementary MOSFET-driver stage transistors T5/T6 and T7/T8.

T6 and T7 are N-channel-enhancement mosfets and T5 and T8 are the complementary P-channel-enhancement mosfets. These transistors correspond to the well-known CMOS basic circuit (CMOS = Complementary MOS), which represents the basic of the CMOS logic family (CMOS inverters).

Only the resistors R44 to R47 are new in this circuit. They provide current limitation during shifting process and protect in cases of disturbances. The control unit ist suitable for inverters up to 10 kW output power. The driver stage transistors T5 to T8 provide the signals for the power mosfets, which alternately magnetize transformer Tr1. Inductive idle currents, how they are needed e. g. by electric motors, can be returned to the battery, thanks to the integrated antiparallel recirculating diodes of the transistors.

Thus they do not generate unnecessary losses, contrary to early inverters. The most important task in our inverter is done by the mosfet transistors T13 to T28. They are connected in two groups, each of 8 transistors. They generate alternatingly the positive and negative wave of the output voltage. Each transistor line works on ist own transformer coil. After a transistor line is beeing switched off, the magnetic energy stored in the magnetic field of the transformer returns back to the battery by the integrated recirculation diodes of the second transistor line. The idle current of consumers with inductive load takes the same way. In case of strong heating up of the transistors, which should only happen on defects in the equipment, the bimetal thermal switch F2 shuts off the control electronics.

In normal operation, temperature of the heat sink should be as low, that you could touch it by your hands. The source-currents of the mosfet transistors pass over resistor R20 with the very 🔗 External reference

The inverter circuit described operates efficiently by employing a square wave generation technique, which is essential for converting low-voltage DC to higher-voltage AC. The oscillator, utilizing an integrated circuit (IC), is critical in establishing the desired frequency output, which can be adjusted based on the application requirements. The use of resistors and capacitors in conjunction with the oscillator IC allows for precise control over the frequency and duty cycle, ensuring that the output voltage is stable and suitable for various loads.

The regulation mechanism, which includes a transistor and diodes, plays a pivotal role in maintaining the output voltage within acceptable limits, particularly when dealing with varying load conditions. The incorporation of MOSFETs in the design enhances efficiency, as they provide rapid switching capabilities and lower on-resistance compared to traditional transistors, leading to reduced heat generation and improved overall performance.

The design also addresses the challenges associated with inductive loads, which are common in practical applications. The ability to recirculate idle currents back to the battery minimizes energy loss and enhances the system's efficiency. Furthermore, the thermal protection implemented through the bimetal switch ensures that the inverter operates safely under varying conditions, preventing damage from overheating.

In summary, this inverter design is robust, with well-considered components that work together to provide a reliable source of AC power from a DC source, suitable for a wide range of applications, including those with inductive loads. The careful selection of components, along with the thoughtful arrangement of the circuit, contributes to its effectiveness and efficiency, making it a valuable solution in power conversion applications.The inverter chops the 12 Volt DC Battery voltage into a square wave voltage of 50 cycles per second and duty cycle of 25%, transformed by transformer Tr1 to 230 Volt rms. IC1 forms the oscillator with 100 cycles per second (120 cycles per second for 60 cycles output). Frequency is determined by C1 and the resistors R4 and R5. Resistor R6 determin s the time of the flyback of the oscillator and affects likewise the frequency. In addition, R6 affects the rms of the output voltage, which must be considered if necessary, if the circuit shall be used for other frequencies. 60 cycles per second can be achieved by alignment, higher frequencies require changes in the frequency-determining parts.

For high stability of frequency, special attention must be spent on condenser C1. Ceramic capacitors are not usefull, due to their high sensitivity on temperature. Most foil condensers may keep the frequency quite constant, even against strong temperature variations. IC2 determines the pulse width and thus rms of the output voltage. The regulater consists of transistor T1, which receives its signal from the diodes D4 and D5, taken from the primary tranformer coil.

The regulator adjusts the output voltage by changing the pulse width. It prevents also rising of rms on inductive or capacitive load. The characteristics of regulation can be adapted by changing D4 (important on 24 Volts applications!). Lower voltage level of D4 results in "softer" regulation, i. e. an reduction of the proportional factor. Against earlier versions of the inverter, IC 8 now will be switched directly by the oscillator signal, thus avoiding errors by unexpected oscillations of the PWM-IC 2.

Here the alternate allocation of the impulses for both transistor lines, i. e. for the positive and the negative half wave of the output voltage takes place. The final frequency of 50 cycles per second develops. Flip-flop IC7 stores a switching off instruction of the current limiter for the rest of the half wave. From the gates IC5 (4093-III) and IC6 (4093-IV), the control signal arrives at the complementary MOSFET-driver stage transistors T5/T6 and T7/T8.

T6 and T7 are N-channel-enhancement mosfets and T5 and T8 are the complementary P-channel-enhancement mosfets. These transistors correspond to the well-known CMOS basic circuit (CMOS = Complementary MOS), which represents the basic of the CMOS logic family (CMOS inverters).

Only the resistors R44 to R47 are new in this circuit. They provide current limitation during shifting process and protect in cases of disturbances. The control unit ist suitable for inverters up to 10 kW output power. The driver stage transistors T5 to T8 provide the signals for the power mosfets, which alternately magnetize transformer Tr1. Inductive idle currents, how they are needed e. g. by electric motors, can be returned to the battery, thanks to the integrated antiparallel recirculating diodes of the transistors.

Thus they do not generate unnecessary losses, contrary to early inverters. The most important task in our inverter is done by the mosfet transistors T13 to T28. They are connected in two groups, each of 8 transistors. They generate alternatingly the positive and negative wave of the output voltage. Each transistor line works on ist own transformer coil. After a transistor line is beeing switched off, the magnetic energy stored in the magnetic field of the transformer returns back to the battery by the integrated recirculation diodes of the second transistor line. The idle current of consumers with inductive load takes the same way. In case of strong heating up of the transistors, which should only happen on defects in the equipment, the bimetal thermal switch F2 shuts off the control electronics.

In normal operation, temperature of the heat sink should be as low, that you could touch it by your hands. The source-currents of the mosfet transistors pass over resistor R20 with the very 🔗 External reference