lfr using 555 timer

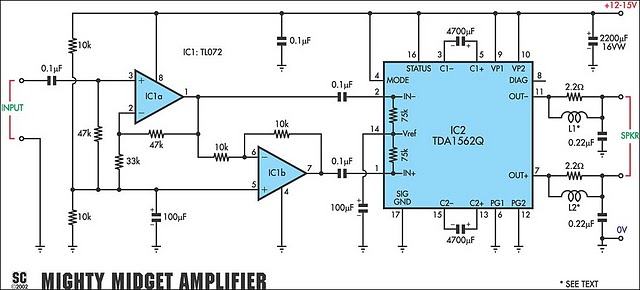

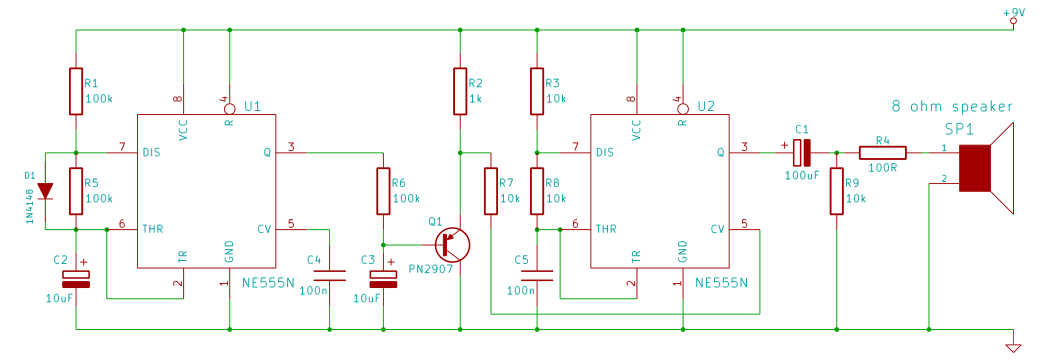

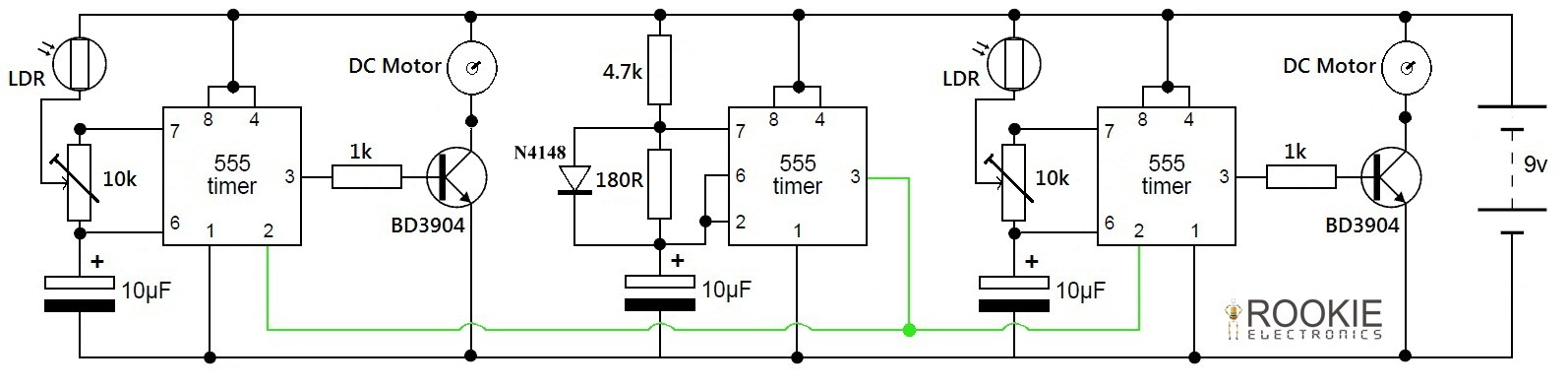

This is a simple and cost-effective approach to a line-following robot. It does not utilize any microcontroller but instead relies on a basic circuit composed of three 555 timers. The robot demonstrates good efficiency in following various curves and can be constructed for under 1000 PKR. Building a reliable and well-functioning robot requires not only electronic skills but also some mechanical knowledge. The most challenging aspect encountered during the construction of this robot was creating tires that fit properly on the motors and designing the robot's structure. Access to a university lathe machine was necessary for tire fabrication, and a woodworking shop was utilized for building the structure. The complete circuit diagram for the line-following robot is provided, although the connections for the LEDs are not included; it is necessary to connect two LEDs in series with a 1k resistor to the positive and negative terminals of the circuit. This circuit is straightforward, as the two 555 timer circuits (excluding the center one) are identical, requiring the construction of two similar circuits. The motors are not directly connected to the outputs of the 555 timers; a transistor is used as a switch. The pin configuration of this transistor is as follows: (1) Emitter, (2) Base, and (3) Collector. This part of the circuit is referred to as the motor driver circuit, where the DC geared motors are connected. Two circuits similar to this one need to be created, with pin number 2 (Trigger) receiving input from the center 555 timer circuit, which is configured as monostable. This means that when triggered, it outputs a pulse that is connected to the transistor, acting as a switch for the motors.

The sensor component is the most crucial part of the line-following robot, as it guides the robot to stay on track. The LDRs (Light Dependent Resistors) serve as the "eyes" of the robot. Long wires are used to connect these sensors to the circuit, allowing flexibility in positioning the sensor board for optimal structure and performance. The LEDs in this section remain continuously illuminated. When the LEDs shine on a black surface, there is no reflection, causing the LDRs to remain dark, which allows the motors to run. Conversely, when the LEDs detect a white line, the light is reflected, causing the LDRs to trigger the motors to turn off. In the robot's structure, the sensor part is not fixed; therefore, it is essential to incorporate a mechanism to securely attach the sensor to the robot's chassis for improved functionality. Maintaining a low height for the sensor part is recommended to enhance efficiency.

The circuit design emphasizes simplicity and effectiveness, ensuring that even those with limited electronic experience can construct a functional line-following robot. The use of 555 timers for control and LDRs for sensing provides a robust solution for the task of line following, making it an excellent project for both educational and practical applications in robotics.This is Simple and cheap approach to Line Following Robot, This do not have anymicro controller but just a simple basic Circuit on three 555 timers. It has a good efficiency on following all kind of curves. This Robot is no more than 1000PKR. To make a reliable and well functioning robot, you just not need Electronics Skills but also a little Mech

anical too. Having a Electronics mind, the most difficult job I felt in making this robot was Tires which would fit Properly in my motors and the Structure of Robot. For these stuff I accessed my University`s Lathe Machine for tires and a Wood Work shop to make the Structure.

Does this circuit looks difficult to you ! wana go for a simpler than this !Click hereto see my Differential Drive based Line following Robot made on just BC108 Transistors. This is complete Diagram of whole circuit for Line Following Robot, but I have not shown the connections for LEDs, So for that, you will have to connect two LEDs in series of 1k resistor with +ve and -ve of this circuit.

Dont feel that this is any difficult circuit, its very simple if you notice that Both 555 Timer circuits(others except center one) are exactly same. So you actually need to built the following two circuits. Our motors are not directly connected to the outputs of 555 Timer, but a transistor is used as a switch.

The Pin Configuration of this transistor is (1)Emitter, (2)Base & (3)Collector I name this Part of the Circuit as Motor Driver Circuit, Now this is a circuit in which our DC geared motors are to be Hooked up, So wee need to make two circuits like this one in which The pin no 2 (Trigger) is given input from the Center 555 Timer Circuit In the above images It is configured as monostable, that means when they are triggered they give a pulse on the ouput pin which is then connected to transistor as switch circuit for motors Sensor part: This is the most important part of the LFR, because it has the sensor which guides the robot to move on Line and donot leave the track EveR ! These LDRS are the eyes of the LFR. As you can see i have kept long wires which i have later connected to circuit, the reason for taking long wires is to be free of placing this strip sensor board anywhere suitable to structure and for perfection.

The LEDs in this part, are all the time ON. The reflection of LEDs is sensed by LDRs. When LEDs are on black area there is no reflection and LDRs are dark (Motors Run) but when LEDs see white line the LDRs are shone some light and hence trigger the Motors to turn off In my Structure as you see in Video, My sensor part is not fixed. When you design your chasis of Robot, must have any technique to fit the sensor part Fixed in the structure.

Make sure to keep sensor part height to be as lowest as possible for higher efficiency 🔗 External reference

The sensor component is the most crucial part of the line-following robot, as it guides the robot to stay on track. The LDRs (Light Dependent Resistors) serve as the "eyes" of the robot. Long wires are used to connect these sensors to the circuit, allowing flexibility in positioning the sensor board for optimal structure and performance. The LEDs in this section remain continuously illuminated. When the LEDs shine on a black surface, there is no reflection, causing the LDRs to remain dark, which allows the motors to run. Conversely, when the LEDs detect a white line, the light is reflected, causing the LDRs to trigger the motors to turn off. In the robot's structure, the sensor part is not fixed; therefore, it is essential to incorporate a mechanism to securely attach the sensor to the robot's chassis for improved functionality. Maintaining a low height for the sensor part is recommended to enhance efficiency.

The circuit design emphasizes simplicity and effectiveness, ensuring that even those with limited electronic experience can construct a functional line-following robot. The use of 555 timers for control and LDRs for sensing provides a robust solution for the task of line following, making it an excellent project for both educational and practical applications in robotics.This is Simple and cheap approach to Line Following Robot, This do not have anymicro controller but just a simple basic Circuit on three 555 timers. It has a good efficiency on following all kind of curves. This Robot is no more than 1000PKR. To make a reliable and well functioning robot, you just not need Electronics Skills but also a little Mech

anical too. Having a Electronics mind, the most difficult job I felt in making this robot was Tires which would fit Properly in my motors and the Structure of Robot. For these stuff I accessed my University`s Lathe Machine for tires and a Wood Work shop to make the Structure.

Does this circuit looks difficult to you ! wana go for a simpler than this !Click hereto see my Differential Drive based Line following Robot made on just BC108 Transistors. This is complete Diagram of whole circuit for Line Following Robot, but I have not shown the connections for LEDs, So for that, you will have to connect two LEDs in series of 1k resistor with +ve and -ve of this circuit.

Dont feel that this is any difficult circuit, its very simple if you notice that Both 555 Timer circuits(others except center one) are exactly same. So you actually need to built the following two circuits. Our motors are not directly connected to the outputs of 555 Timer, but a transistor is used as a switch.

The Pin Configuration of this transistor is (1)Emitter, (2)Base & (3)Collector I name this Part of the Circuit as Motor Driver Circuit, Now this is a circuit in which our DC geared motors are to be Hooked up, So wee need to make two circuits like this one in which The pin no 2 (Trigger) is given input from the Center 555 Timer Circuit In the above images It is configured as monostable, that means when they are triggered they give a pulse on the ouput pin which is then connected to transistor as switch circuit for motors Sensor part: This is the most important part of the LFR, because it has the sensor which guides the robot to move on Line and donot leave the track EveR ! These LDRS are the eyes of the LFR. As you can see i have kept long wires which i have later connected to circuit, the reason for taking long wires is to be free of placing this strip sensor board anywhere suitable to structure and for perfection.

The LEDs in this part, are all the time ON. The reflection of LEDs is sensed by LDRs. When LEDs are on black area there is no reflection and LDRs are dark (Motors Run) but when LEDs see white line the LDRs are shone some light and hence trigger the Motors to turn off In my Structure as you see in Video, My sensor part is not fixed. When you design your chasis of Robot, must have any technique to fit the sensor part Fixed in the structure.

Make sure to keep sensor part height to be as lowest as possible for higher efficiency 🔗 External reference