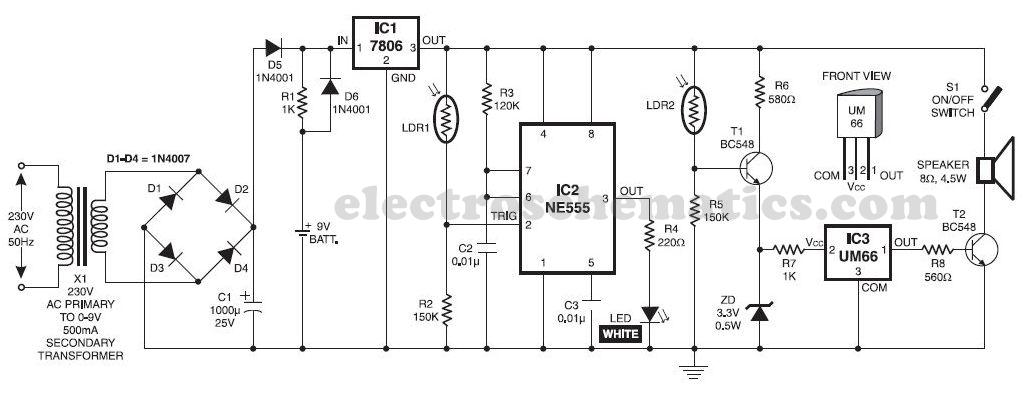

Light Sensitive trigger

All components have been placed on the PCB, but there is uncertainty regarding the connection of the power and load in relation to the relays.

The integration of relays into a printed circuit board (PCB) design requires a clear understanding of their function and the necessary connections for both power and load management. Relays act as electrically operated switches that can control a high-power circuit using a low-power signal.

To connect the power and load correctly, the following steps should be taken:

1. **Identify Relay Specifications**: Determine the relay's coil voltage and contact ratings. This information is crucial for ensuring that the relay can handle the intended load and that the control signal matches the relay's coil requirements.

2. **Power Supply Connection**: Connect the relay coil terminals to the appropriate power supply. The positive terminal of the power supply should be connected to one coil terminal, while the other terminal connects to a control switch or microcontroller output. Ensure that the control signal voltage matches the relay coil voltage specification.

3. **Load Connection**: The load should be connected to the relay's contact terminals. Typically, a relay will have Normally Open (NO) and Normally Closed (NC) contacts. For switching applications, connect the load to the NO terminal if the load should be powered when the relay is activated. The other terminal (COM) should connect back to the power supply.

4. **Protection Circuit**: It is advisable to include a flyback diode across the relay coil terminals to protect the circuit from voltage spikes generated when the relay is de-energized. The cathode of the diode should be connected to the positive terminal of the coil.

5. **Testing the Circuit**: Once all connections are made, it is essential to test the relay operation. This can be done by activating the control signal and observing whether the load is powered as intended.

By following these guidelines, the relay can be effectively integrated into the PCB, ensuring reliable operation for controlling power to the load.I have put all the components on the PCB, now i dont know anything about relays, so i`m having trouble connecting the power and the load?.. 🔗 External reference

The integration of relays into a printed circuit board (PCB) design requires a clear understanding of their function and the necessary connections for both power and load management. Relays act as electrically operated switches that can control a high-power circuit using a low-power signal.

To connect the power and load correctly, the following steps should be taken:

1. **Identify Relay Specifications**: Determine the relay's coil voltage and contact ratings. This information is crucial for ensuring that the relay can handle the intended load and that the control signal matches the relay's coil requirements.

2. **Power Supply Connection**: Connect the relay coil terminals to the appropriate power supply. The positive terminal of the power supply should be connected to one coil terminal, while the other terminal connects to a control switch or microcontroller output. Ensure that the control signal voltage matches the relay coil voltage specification.

3. **Load Connection**: The load should be connected to the relay's contact terminals. Typically, a relay will have Normally Open (NO) and Normally Closed (NC) contacts. For switching applications, connect the load to the NO terminal if the load should be powered when the relay is activated. The other terminal (COM) should connect back to the power supply.

4. **Protection Circuit**: It is advisable to include a flyback diode across the relay coil terminals to protect the circuit from voltage spikes generated when the relay is de-energized. The cathode of the diode should be connected to the positive terminal of the coil.

5. **Testing the Circuit**: Once all connections are made, it is essential to test the relay operation. This can be done by activating the control signal and observing whether the load is powered as intended.

By following these guidelines, the relay can be effectively integrated into the PCB, ensuring reliable operation for controlling power to the load.I have put all the components on the PCB, now i dont know anything about relays, so i`m having trouble connecting the power and the load?.. 🔗 External reference