Medical ultrasonic atomizer 2

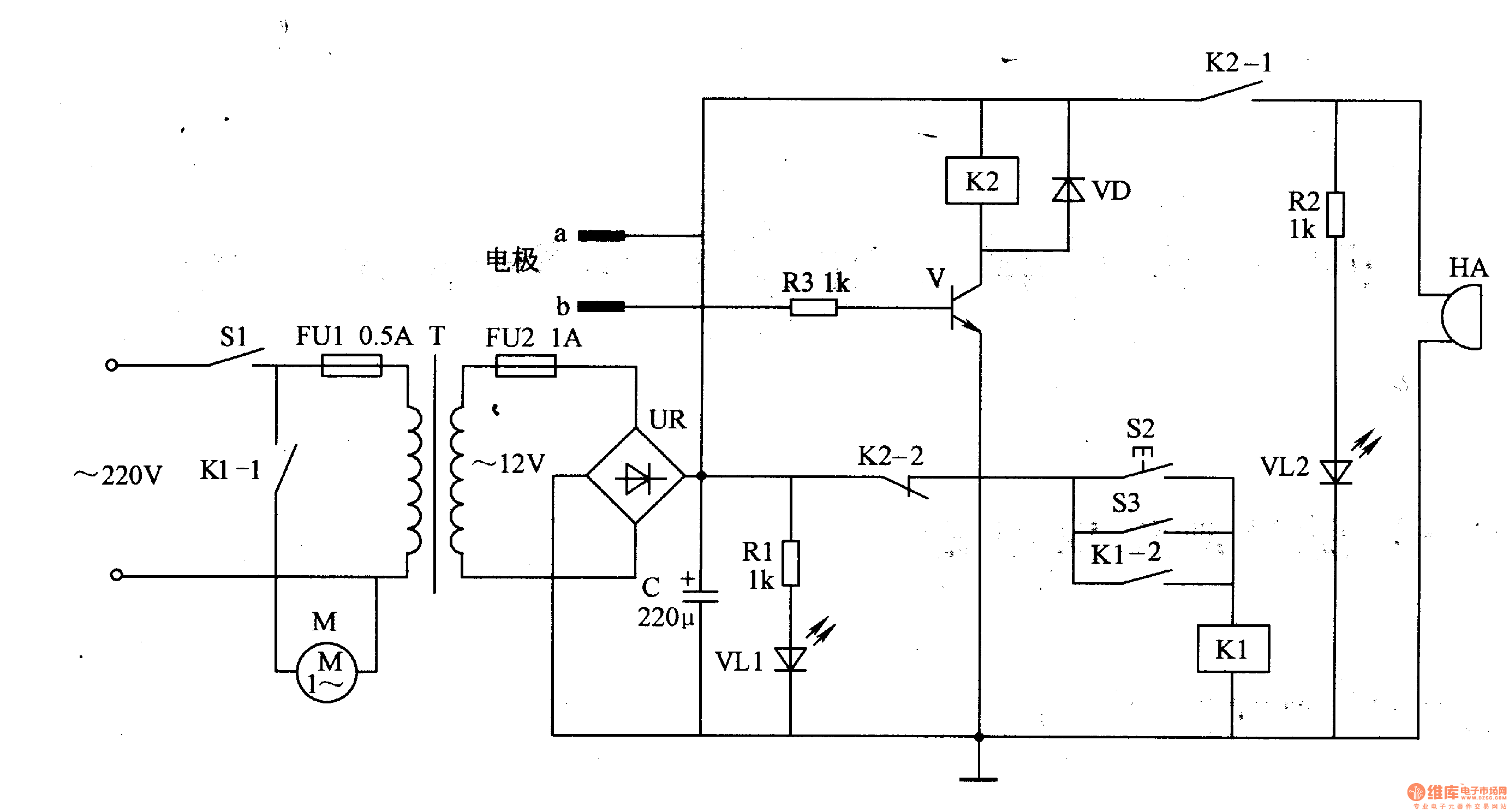

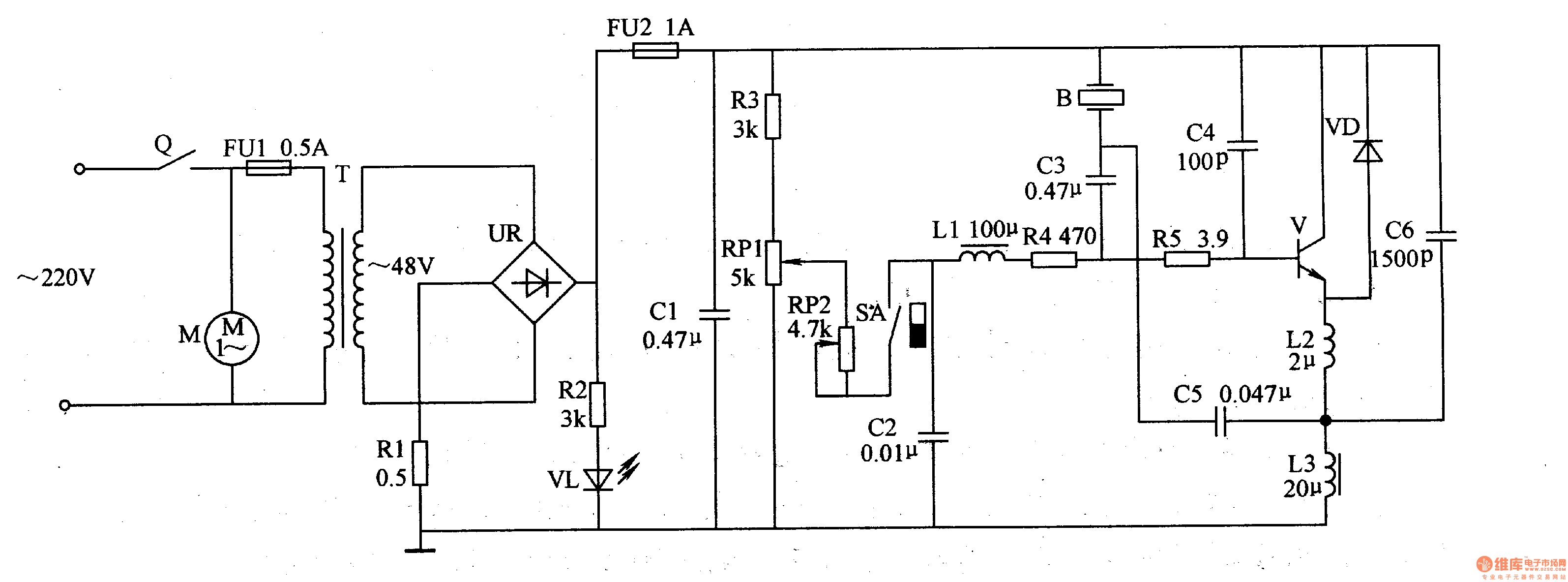

The medical ultrasonic atomizer circuit consists of a power supply circuit, an atomization amount liquid level detection control circuit, an ultrasonic oscillator, and a fan motor (M). The power supply circuit includes a timer (Q), fuses (FU1, FU2), a power transformer (T), bridge rectifiers (UR), resistors (R1, R2), an LED (VL), and a filter capacitor (C1). The atomization amount and liquid level detection control circuit is made up of a resistor (R3), potentiometers (RP1, RP2), a magnetic control water level switch (SA) which comprises a float with a magnetic ring and a reed switch, and a capacitor (C2).

The medical ultrasonic atomizer circuit is designed to efficiently generate mist from a liquid, which is particularly useful in medical applications such as respiratory therapy. The power supply circuit plays a crucial role in providing the necessary voltage and current to the entire system. The timer (Q) is responsible for controlling the operation time of the atomizer, ensuring that the device operates only when required. Fuses (FU1, FU2) are included for overcurrent protection, safeguarding the circuit from potential damage due to excessive current flow.

The power transformer (T) steps down the mains voltage to a suitable level for the circuit. The bridge rectifiers (UR) convert the alternating current (AC) output from the transformer into direct current (DC), which is then smoothed by the filter capacitor (C1) to provide a stable voltage supply. Resistors (R1, R2) are used to limit current and set biasing levels for various components, while the LED (VL) serves as a power indicator, illuminating when the circuit is active.

The atomization amount and liquid level detection control circuit is integral for ensuring optimal operation of the atomizer. Resistor (R3) and potentiometers (RP1, RP2) are utilized for adjusting the sensitivity and response of the liquid level detection system. The magnetic control water level switch (SA) operates based on the position of a float, which rises and falls with the liquid level. The embedded magnetic ring activates the reed switch when the liquid reaches a certain level, providing feedback to the control circuit. Capacitor (C2) is used for stabilizing the control signal and filtering out noise, ensuring reliable operation of the liquid level detection system.

Overall, this circuit design provides a comprehensive solution for atomizing liquids in a controlled manner, utilizing ultrasonic technology for effective mist generation while incorporating safety features and responsive control mechanisms.The medical ultrasonic atomizer circuit is composed of power supply circuit, atomization amount liquid level detection control circuit, ultrasonic oscillator and fan motor M, it is shown in the figure 9-111. The power supply circuit is made of timer Q, fuses FU1, FU2, power transformer T, bridge rectifiers UR, resistors R1, R2, LED VL and filter c

apacitor C1. The atomization amount/liquid level detection control circuit consists of resistor R3, potentiometers RP1, RP2, magnetic control water level switch SA(it is composed of float with magnetic ring and reed switch)and capacitor C2. 🔗 External reference

The medical ultrasonic atomizer circuit is designed to efficiently generate mist from a liquid, which is particularly useful in medical applications such as respiratory therapy. The power supply circuit plays a crucial role in providing the necessary voltage and current to the entire system. The timer (Q) is responsible for controlling the operation time of the atomizer, ensuring that the device operates only when required. Fuses (FU1, FU2) are included for overcurrent protection, safeguarding the circuit from potential damage due to excessive current flow.

The power transformer (T) steps down the mains voltage to a suitable level for the circuit. The bridge rectifiers (UR) convert the alternating current (AC) output from the transformer into direct current (DC), which is then smoothed by the filter capacitor (C1) to provide a stable voltage supply. Resistors (R1, R2) are used to limit current and set biasing levels for various components, while the LED (VL) serves as a power indicator, illuminating when the circuit is active.

The atomization amount and liquid level detection control circuit is integral for ensuring optimal operation of the atomizer. Resistor (R3) and potentiometers (RP1, RP2) are utilized for adjusting the sensitivity and response of the liquid level detection system. The magnetic control water level switch (SA) operates based on the position of a float, which rises and falls with the liquid level. The embedded magnetic ring activates the reed switch when the liquid reaches a certain level, providing feedback to the control circuit. Capacitor (C2) is used for stabilizing the control signal and filtering out noise, ensuring reliable operation of the liquid level detection system.

Overall, this circuit design provides a comprehensive solution for atomizing liquids in a controlled manner, utilizing ultrasonic technology for effective mist generation while incorporating safety features and responsive control mechanisms.The medical ultrasonic atomizer circuit is composed of power supply circuit, atomization amount liquid level detection control circuit, ultrasonic oscillator and fan motor M, it is shown in the figure 9-111. The power supply circuit is made of timer Q, fuses FU1, FU2, power transformer T, bridge rectifiers UR, resistors R1, R2, LED VL and filter c

apacitor C1. The atomization amount/liquid level detection control circuit consists of resistor R3, potentiometers RP1, RP2, magnetic control water level switch SA(it is composed of float with magnetic ring and reed switch)and capacitor C2. 🔗 External reference