Model Railroad OdometerCar

The Car shows the distance a train travels on a 5 digit LCD display. The distance is indicated down to 1/100th of a mile (about the length of a 50 foot car) with an accuracy of approximately plus 2 percent using a standard 33 inch freight car wheel. Simply stated, the Odometer Car counts the number of revolutions of one of the axles, divides it by six and displays the result on the counter module. More: The magazine article lists the TIL 139 as the part number for the emitter detector module but the ECG 3104 would be a better choice as it is much smaller and would be easier to mount using a small section of printed circuit board. The ECG 3104 will be eas

The described system utilizes a five-digit LCD display to provide real-time distance measurements for a train, specifically calibrated to show distances down to 1/100th of a mile. This precision is particularly useful for applications requiring accurate tracking of distances, such as in railway operations where even minor discrepancies can lead to significant operational inefficiencies.

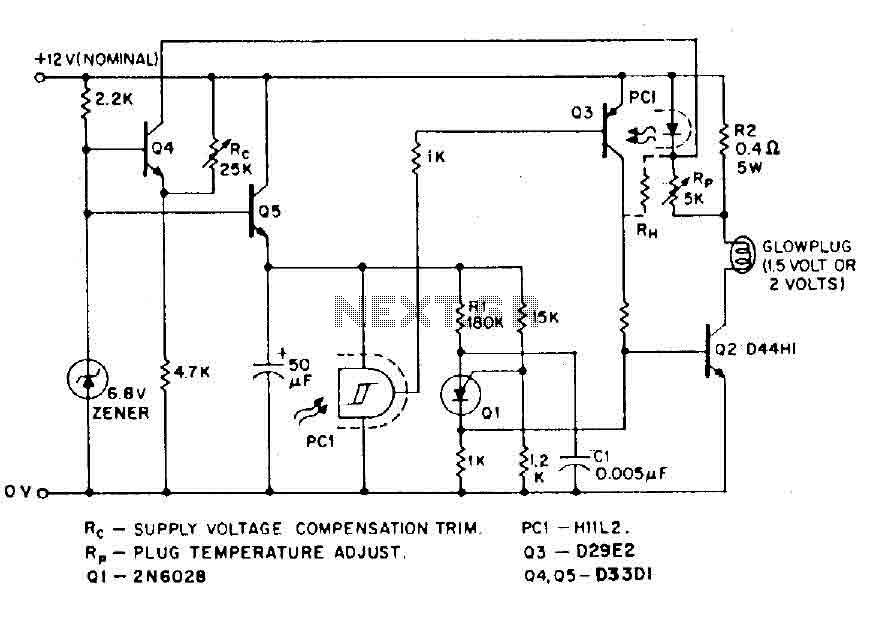

The fundamental operating principle of the Odometer Car involves counting the revolutions of one of the train's axles. This is achieved through a sensor module that detects the rotation of the axle. The system divides the total number of revolutions by six, which correlates to the train's wheel diameter and gear ratio, thereby converting the mechanical motion into a distance measurement. The calculated distance is then displayed on the LCD, allowing for easy reading and monitoring by the operator.

For the emitter-detector module, two components are mentioned: the TIL 139 and the ECG 3104. The TIL 139 is a standard choice, but the ECG 3104 is recommended due to its smaller size, which facilitates easier integration onto a printed circuit board (PCB). The reduced footprint of the ECG 3104 not only simplifies the mounting process but also enhances the overall design by minimizing space requirements and potentially reducing the weight of the assembly.

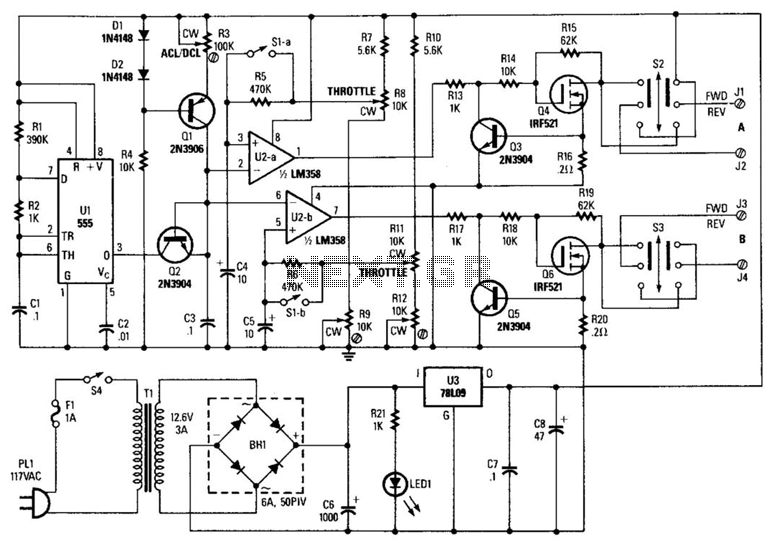

In terms of circuit design, the system would typically include a microcontroller that interfaces with the sensor module to process the input from the axle rotation. The microcontroller would execute the necessary calculations to convert revolutions into distance and manage the output to the LCD display. Additional components might include resistors, capacitors, and possibly operational amplifiers to ensure signal integrity and stability.

Power supply considerations must also be accounted for, ensuring that the system operates efficiently within the voltage and current ratings of the components used. This could involve the use of voltage regulators or battery management systems if a portable power source is employed.

Overall, the combination of a precise distance measurement system, an efficient processing unit, and a user-friendly display creates a comprehensive solution for monitoring train travel distances accurately.The Car shows the distance a train travels on a 5 digit LCD display. The distance is indicated down to 1/100th of a mile (about the length of a 50 foot car) with an accuracy of approximately plus 2 percent using a standard 33 inch freight car wheel. Simply stated, the Odometer Car counts the number of revolutions of one of the axles, divides it by six and displays the result on the counter module.

The magazine article lists the TIL 139 as the part number for the emitter detector module but the ECG 3104 would be a better choice as it is much smaller and would be easier to mount using a small section of printed circuit board. The ECG 3104 will be eas 🔗 External reference

The described system utilizes a five-digit LCD display to provide real-time distance measurements for a train, specifically calibrated to show distances down to 1/100th of a mile. This precision is particularly useful for applications requiring accurate tracking of distances, such as in railway operations where even minor discrepancies can lead to significant operational inefficiencies.

The fundamental operating principle of the Odometer Car involves counting the revolutions of one of the train's axles. This is achieved through a sensor module that detects the rotation of the axle. The system divides the total number of revolutions by six, which correlates to the train's wheel diameter and gear ratio, thereby converting the mechanical motion into a distance measurement. The calculated distance is then displayed on the LCD, allowing for easy reading and monitoring by the operator.

For the emitter-detector module, two components are mentioned: the TIL 139 and the ECG 3104. The TIL 139 is a standard choice, but the ECG 3104 is recommended due to its smaller size, which facilitates easier integration onto a printed circuit board (PCB). The reduced footprint of the ECG 3104 not only simplifies the mounting process but also enhances the overall design by minimizing space requirements and potentially reducing the weight of the assembly.

In terms of circuit design, the system would typically include a microcontroller that interfaces with the sensor module to process the input from the axle rotation. The microcontroller would execute the necessary calculations to convert revolutions into distance and manage the output to the LCD display. Additional components might include resistors, capacitors, and possibly operational amplifiers to ensure signal integrity and stability.

Power supply considerations must also be accounted for, ensuring that the system operates efficiently within the voltage and current ratings of the components used. This could involve the use of voltage regulators or battery management systems if a portable power source is employed.

Overall, the combination of a precise distance measurement system, an efficient processing unit, and a user-friendly display creates a comprehensive solution for monitoring train travel distances accurately.The Car shows the distance a train travels on a 5 digit LCD display. The distance is indicated down to 1/100th of a mile (about the length of a 50 foot car) with an accuracy of approximately plus 2 percent using a standard 33 inch freight car wheel. Simply stated, the Odometer Car counts the number of revolutions of one of the axles, divides it by six and displays the result on the counter module.

The magazine article lists the TIL 139 as the part number for the emitter detector module but the ECG 3104 would be a better choice as it is much smaller and would be easier to mount using a small section of printed circuit board. The ECG 3104 will be eas 🔗 External reference