mouse

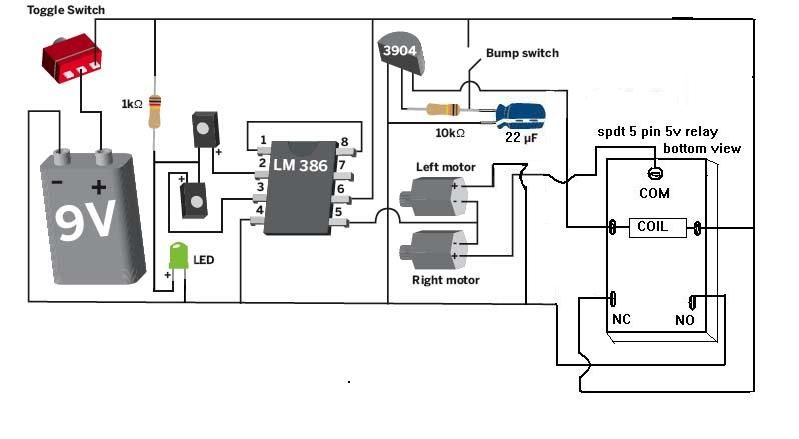

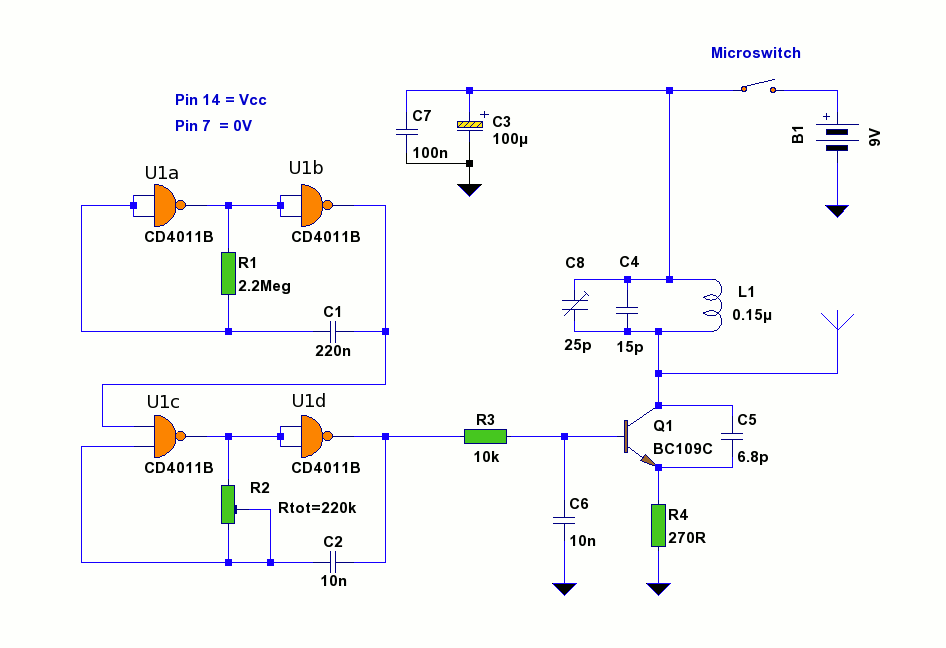

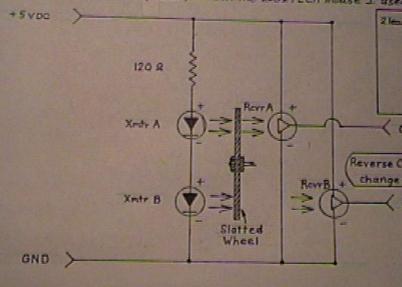

This page provides information on converting low-resolution optical encoders, typically found in serial mice, into high-resolution encoders suitable for Digital Setting Circles (DSCs) for telescopes. The serial mouse encoders examined had the DPI (dots per inch) value stamped on the side of the slotted disk; in one instance, a value of 200 was noted. The mouse must be of the serial type, such as a Logitech three-button mouse, which connects to the serial port. Avoid using common two-button mice that connect to the mouse port, as they utilize continuous turn potentiometers instead of optical encoders. Serial mice already have a serial interface for the optical encoders, and it is feasible to reuse that section of the circuit board if direct interfacing with the computer's serial port is required. In this case, the portion was discarded during disassembly. The software used should prompt for the encoder resolution, which can be calculated by multiplying the DPI by the circumference of the bearing surface, assuming the encoders are mounted similarly. Testing involves rotating the axis through a known number of degrees, ideally a full 360, and monitoring the readout to ensure proper tracking. If discrepancies arise, adjustments to the final resolution should be made and retested. In the absence of a stamped DPI, counting the number of slots in the disk and multiplying by four, followed by measuring the diameter of the drive wheel and dividing the previous calculation by (pi times the diameter in inches), will yield an approximate DPI. The resulting value should closely match a standard DPI. The mounting system can be described as an "isolated pressure roller transmission," allowing for delicate pressure on the encoder side and heavier pressure on the telescope's axis bearing, resulting in zero slippage and zero backlash. Some periodic error may occur, but it is generally unnoticeable during telescope use. Eccentricity in the azimuth bearing does not significantly affect performance. When using encoders for tracking, periodic error can be incorporated into an appropriate algorithm, albeit complicating the design. The achieved resolution on the elevation bearing is approximately 4500 counts, given a bearing diameter of 7 1/4 inches, while the azimuth bearing resolution exceeds 9000 counts. Serial mouse encoders can function effectively with careful design and larger axis bearings. However, using smaller axis bearings or requiring direct drive encoders may not yield satisfactory results. For example, a 200 DPI mouse encoder necessitates a minimum 6 1/2 inch diameter bearing to achieve the recommended 4000 counts of resolution, while a 400 DPI encoder requires only a 3 1/4 inch diameter bearing. Accompanying images depict a Logitech three-button mouse printed circuit board similar to the one utilized, with identical optical chips and slotted wheels, although the serial interface IC may differ. To dissect the board, it is advisable to first remove the large rectangular IC without damaging the board. The IC leads can be clipped if specialized tools are unavailable, and the pins can be unsoldered individually. All other components should be removed, except for the eight optical chips, the housing containing the encoder shafts and slotted wheels, and the 120-ohm resistors.

The conversion of low-resolution optical encoders from serial mice into high-resolution encoders for telescopes involves several key steps and considerations. The process begins with selecting an appropriate serial mouse, ensuring it features optical encoders rather than potentiometers. The disassembly of the mouse involves careful extraction of the circuit board, preserving the optical components integral to the encoder's function.

Once the encoders are extracted, they must be mounted onto the telescope's axis bearing. The mounting system should be designed to minimize slippage and backlash, which can significantly affect tracking accuracy. The "isolated pressure roller transmission" design allows for controlled pressure application, ensuring that the encoder maintains contact with the bearing surface without excessive force that could lead to wear or inaccuracies.

Calculating the resolution of the encoders is critical for accurate tracking. The DPI value, either obtained from the encoder or calculated through the number of slots and bearing diameter, directly influences the performance of the system. The resolution must be matched to the physical dimensions of the bearing to ensure that the output counts are sufficient for precise movements.

Testing the system involves rotating the telescope's axis and monitoring the output to verify that it corresponds to the expected degrees of rotation. Adjustments to the calculated DPI may be necessary based on the results of these tests to refine the performance further.

In summary, this conversion process requires careful selection of components, precise calculations, and thorough testing to ensure that the resulting high-resolution encoders meet the demands of astronomical applications. With the right approach, serial mouse encoders can provide a reliable and effective solution for digital setting circles in telescopes.This page is for info on converting the low resolution optical encoders, typically found in serial mice, into high resolution encoders needed for DSC`s (Digital Setting Circles), for your telescope, etc. The serial mouse encoders I found had the dpi stamped right in the side of the slotted disk 1, in my case 200 was stamped in the side.

The mouse must be a serial type (like a logitech 3 button mouse), the type that plugs into the serial port. Do not use the common 2 mouse that plugs into the mouse port, they use continuous turn pots, not optical encoders.

The serial mice have a serial interface for the optical encoders already and there isn`t any reason why you couldn`t reuse that portion of the circuit board as well if you needed to interface directly to your computer`s serial port. In my case I discarded that portion when I dissected mine with a jewelers saw as I didn`t need it. The program you use should somewhere ask for the resolution of the encoders and you can calculate an initial setting based on the dpi times the circumference of your bearing surface, if you attach the encoders like I did.

Once you have them working, you test it by rotating the axis through a known number of degrees, preferably a full 360 and watch the readout on your program or digital setting circles to make sure it tracks properly. If there is a difference, simply adjust your final resolution to compensate and then retest. In case the dpi isn`t stamped in the side simply count the number of slots in the disk and multiply by four, then take a micrometer and measure the diameter of the little drive wheel on the encoder shaft and divide the previous calculation by (pi times the dia in inches) and it should give you the dpi.

The result should come very close to a standard dpi. If I were to describe my mounting system, (you can see it is actually very simple), I would call it an "isolated pressure roller transmission" in order that I can use a delicate pressure on the encoder side and a heavier pressure on the axis bearing of the telescope. This way I end up with a zero slippage, zero backlash encoder. It is possible that there is a bit of periodic error, in fact there has to be some, but with the way I use my telescope I do not notice it.

I even have some visable eccentricty in my azimuth bearing and the system still works fine. If you were using the encoders to track with you could factor in any periodic error in an appropriate algorithim anyway, that of course complicates things a little more. The resolution I am getting on my elevation bearing is around 4500 counts as I have a 7 1/4 inch diameter bearing.

My azimuth bearing resolution ends up being over 9000 counts. The bottom line is that serial mouse encoders can work fine if you are careful with your design and use large axis bearings. If you have have either too small of axis bearings or require direct drive encoders this method isn`t going to work too well for you.

EXAMPLE - For a 200dpi mouse encoder you will need at least a 6 1/2 inch diameter bearing to give the recommended 4000 counts of resolution, ie: for a 400 dpi mouse encoder you only need a 3 1/4 inch diameter bearing. Above are three pictures of a LOGITECH 3 Button mouse Printed Circuit Board very similar to the one I used.

The optical chips and slotted wheels are identical to what I used, however the serial interface IC is different. The best way to dissect the board in this case is to first remove that large rectangular IC, don`t damage the board at this point.

You can clip the leads of the IC if you don`t have specialized tools, and then unsolder the pins individually. Remove all other components except, do not remove the the eight optical chips, the housing that carries the encoder shafts and slotted wheels, and the 120 ohm resistors

🔗 External reference

The conversion of low-resolution optical encoders from serial mice into high-resolution encoders for telescopes involves several key steps and considerations. The process begins with selecting an appropriate serial mouse, ensuring it features optical encoders rather than potentiometers. The disassembly of the mouse involves careful extraction of the circuit board, preserving the optical components integral to the encoder's function.

Once the encoders are extracted, they must be mounted onto the telescope's axis bearing. The mounting system should be designed to minimize slippage and backlash, which can significantly affect tracking accuracy. The "isolated pressure roller transmission" design allows for controlled pressure application, ensuring that the encoder maintains contact with the bearing surface without excessive force that could lead to wear or inaccuracies.

Calculating the resolution of the encoders is critical for accurate tracking. The DPI value, either obtained from the encoder or calculated through the number of slots and bearing diameter, directly influences the performance of the system. The resolution must be matched to the physical dimensions of the bearing to ensure that the output counts are sufficient for precise movements.

Testing the system involves rotating the telescope's axis and monitoring the output to verify that it corresponds to the expected degrees of rotation. Adjustments to the calculated DPI may be necessary based on the results of these tests to refine the performance further.

In summary, this conversion process requires careful selection of components, precise calculations, and thorough testing to ensure that the resulting high-resolution encoders meet the demands of astronomical applications. With the right approach, serial mouse encoders can provide a reliable and effective solution for digital setting circles in telescopes.This page is for info on converting the low resolution optical encoders, typically found in serial mice, into high resolution encoders needed for DSC`s (Digital Setting Circles), for your telescope, etc. The serial mouse encoders I found had the dpi stamped right in the side of the slotted disk 1, in my case 200 was stamped in the side.

The mouse must be a serial type (like a logitech 3 button mouse), the type that plugs into the serial port. Do not use the common 2 mouse that plugs into the mouse port, they use continuous turn pots, not optical encoders.

The serial mice have a serial interface for the optical encoders already and there isn`t any reason why you couldn`t reuse that portion of the circuit board as well if you needed to interface directly to your computer`s serial port. In my case I discarded that portion when I dissected mine with a jewelers saw as I didn`t need it. The program you use should somewhere ask for the resolution of the encoders and you can calculate an initial setting based on the dpi times the circumference of your bearing surface, if you attach the encoders like I did.

Once you have them working, you test it by rotating the axis through a known number of degrees, preferably a full 360 and watch the readout on your program or digital setting circles to make sure it tracks properly. If there is a difference, simply adjust your final resolution to compensate and then retest. In case the dpi isn`t stamped in the side simply count the number of slots in the disk and multiply by four, then take a micrometer and measure the diameter of the little drive wheel on the encoder shaft and divide the previous calculation by (pi times the dia in inches) and it should give you the dpi.

The result should come very close to a standard dpi. If I were to describe my mounting system, (you can see it is actually very simple), I would call it an "isolated pressure roller transmission" in order that I can use a delicate pressure on the encoder side and a heavier pressure on the axis bearing of the telescope. This way I end up with a zero slippage, zero backlash encoder. It is possible that there is a bit of periodic error, in fact there has to be some, but with the way I use my telescope I do not notice it.

I even have some visable eccentricty in my azimuth bearing and the system still works fine. If you were using the encoders to track with you could factor in any periodic error in an appropriate algorithim anyway, that of course complicates things a little more. The resolution I am getting on my elevation bearing is around 4500 counts as I have a 7 1/4 inch diameter bearing.

My azimuth bearing resolution ends up being over 9000 counts. The bottom line is that serial mouse encoders can work fine if you are careful with your design and use large axis bearings. If you have have either too small of axis bearings or require direct drive encoders this method isn`t going to work too well for you.

EXAMPLE - For a 200dpi mouse encoder you will need at least a 6 1/2 inch diameter bearing to give the recommended 4000 counts of resolution, ie: for a 400 dpi mouse encoder you only need a 3 1/4 inch diameter bearing. Above are three pictures of a LOGITECH 3 Button mouse Printed Circuit Board very similar to the one I used.

The optical chips and slotted wheels are identical to what I used, however the serial interface IC is different. The best way to dissect the board in this case is to first remove that large rectangular IC, don`t damage the board at this point.

You can clip the leads of the IC if you don`t have specialized tools, and then unsolder the pins individually. Remove all other components except, do not remove the the eight optical chips, the housing that carries the encoder shafts and slotted wheels, and the 120 ohm resistors

🔗 External reference