Neon Desklamp

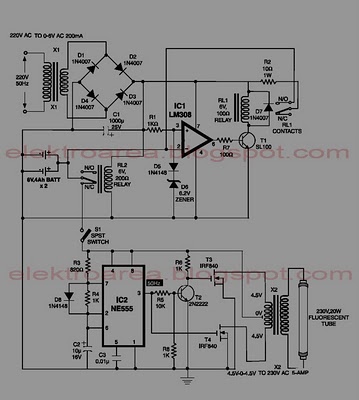

This circuit powers a 6-inch, 4-watt fluorescent tube using a 12-volt supply, with a current consumption of 300 mA.

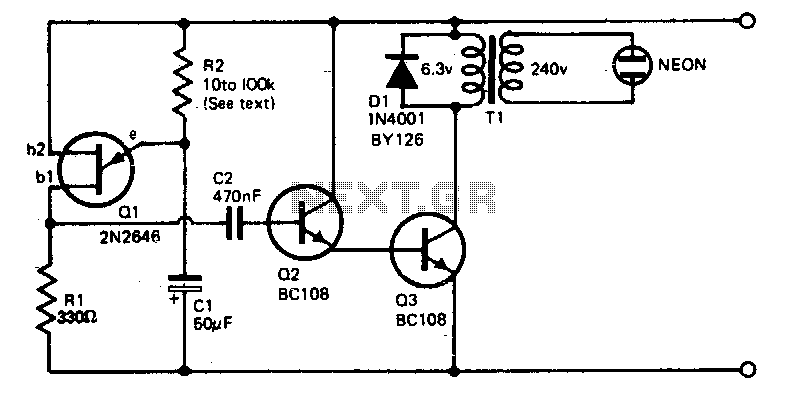

The circuit designed for powering a 6-inch, 4-watt fluorescent tube from a 12-volt supply consists of several key components to ensure efficient operation and reliable performance. The primary components include a transformer or inverter, a ballast, and the fluorescent tube itself.

The circuit begins with a 12-volt DC supply, which may come from a battery or an AC to DC converter. The voltage needs to be converted to a higher AC voltage suitable for the fluorescent tube. This can be achieved using a small inverter circuit that steps up the voltage. The inverter typically consists of a switching device such as a transistor or MOSFET, which alternates the current flow to create an AC output.

Next, a ballast is required to regulate the current flowing through the fluorescent tube. The ballast limits the current to prevent the tube from drawing excessive power, which could lead to overheating and failure. In this case, an electronic ballast may be used for better efficiency and to provide a more stable operation compared to traditional magnetic ballasts.

The fluorescent tube operates by ionizing the gas inside the tube, which emits ultraviolet light when an electric current passes through it. This ultraviolet light then excites a phosphor coating on the inside of the tube, producing visible light. The specifications of the tube indicate that it operates at 4 watts and requires a current of 300 mA. Therefore, the ballast must be designed to maintain this current level while accommodating the tube's electrical characteristics.

In summary, the circuit consists of a 12-volt DC supply, an inverter to step up the voltage, an electronic ballast to regulate current, and the fluorescent tube itself. Proper design considerations must be taken into account to ensure efficient operation, including component ratings, thermal management, and circuit protection features. This setup provides a practical solution for illuminating spaces with a compact fluorescent tube while utilizing a common 12-volt power source.This circuit will power a 6 inch 4 Watt fluorescent tube off a 12 volt supply, consuming 300 mA. 🔗 External reference

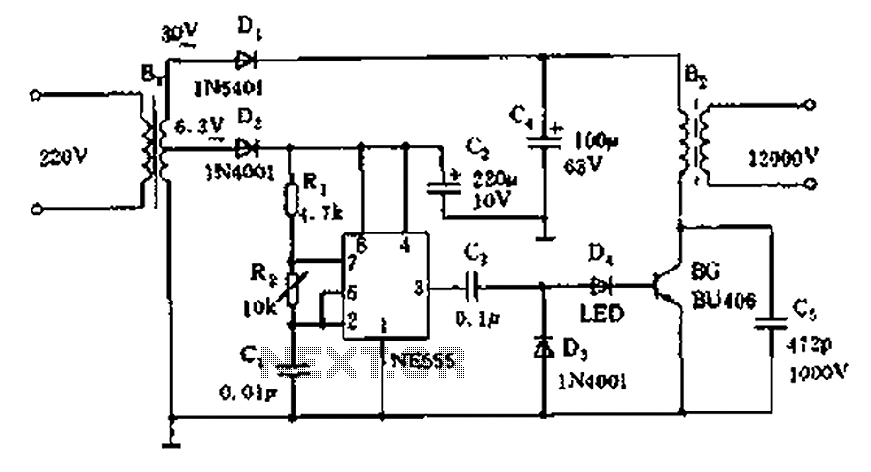

The circuit designed for powering a 6-inch, 4-watt fluorescent tube from a 12-volt supply consists of several key components to ensure efficient operation and reliable performance. The primary components include a transformer or inverter, a ballast, and the fluorescent tube itself.

The circuit begins with a 12-volt DC supply, which may come from a battery or an AC to DC converter. The voltage needs to be converted to a higher AC voltage suitable for the fluorescent tube. This can be achieved using a small inverter circuit that steps up the voltage. The inverter typically consists of a switching device such as a transistor or MOSFET, which alternates the current flow to create an AC output.

Next, a ballast is required to regulate the current flowing through the fluorescent tube. The ballast limits the current to prevent the tube from drawing excessive power, which could lead to overheating and failure. In this case, an electronic ballast may be used for better efficiency and to provide a more stable operation compared to traditional magnetic ballasts.

The fluorescent tube operates by ionizing the gas inside the tube, which emits ultraviolet light when an electric current passes through it. This ultraviolet light then excites a phosphor coating on the inside of the tube, producing visible light. The specifications of the tube indicate that it operates at 4 watts and requires a current of 300 mA. Therefore, the ballast must be designed to maintain this current level while accommodating the tube's electrical characteristics.

In summary, the circuit consists of a 12-volt DC supply, an inverter to step up the voltage, an electronic ballast to regulate current, and the fluorescent tube itself. Proper design considerations must be taken into account to ensure efficient operation, including component ratings, thermal management, and circuit protection features. This setup provides a practical solution for illuminating spaces with a compact fluorescent tube while utilizing a common 12-volt power source.This circuit will power a 6 inch 4 Watt fluorescent tube off a 12 volt supply, consuming 300 mA. 🔗 External reference