obstacle detection sensor circuit

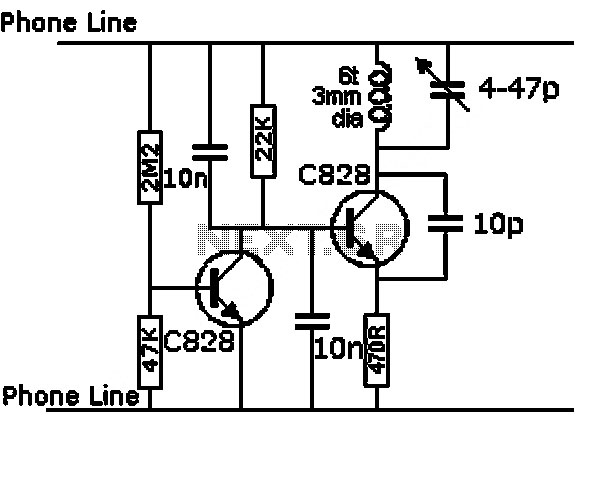

The robot requires a method for detecting obstacles (or other robots) without making physical contact. This capability allows the robot to determine whether to avoid or confront and investigate the obstacle based on its programming. This document outlines the design of the obstacle detection circuit. In this circuit, ultrasonic transducers were selected due to their reliability and superior range compared to infrared (IR) sensors, which can be affected by ambient light levels. The integrated circuit U1 is a 555 timer configured in astable mode to oscillate at 40 kHz. Instead of using fixed resistor values between pins 6 and 7, a 10 kΩ potentiometer (VR1) is employed, allowing for fine-tuning of the output frequency. The output from pin 3 is connected to a 40 kHz ultrasonic transmitter (UTR1). The receiving circuit utilizes a dual LM358N operational amplifier (U2). An ultrasonic receiver (UTR2) is connected to pin 3, the non-inverting input of U2a, which acts as a non-inverting amplifier with a gain of 220. The output from U2a is passed through a low-pass filter composed of D1, C3, and R4 to produce a stable DC voltage. This DC voltage is then fed into the non-inverting input of U2b, which is configured as a non-inverting comparator. The sensitivity of U2b is adjusted using VR2 to set the threshold trigger value. The output of U2b is connected through R5 to the base of a bipolar 2N2222 transistor (Q1), which functions as an inverter, connected to an LED (LED1) to signal when an obstacle has been detected. Finally, the collector of Q1 is connected to the digital port of the Handy Board, which operates on inverted logic levels, where 0V represents a logic high (1) and +5V represents a logic low (0).

The described obstacle detection circuit employs ultrasonic technology to facilitate non-contact sensing capabilities in robotic applications. The choice of a 555 timer in astable mode for generating a 40 kHz signal is critical, as this frequency is optimal for ultrasonic transmission and reception, allowing for effective detection of obstacles at varying distances. The inclusion of a potentiometer for frequency adjustment provides flexibility in tuning the system to account for environmental factors and specific application requirements.

The use of the LM358N op-amp in the receiving circuit enhances the sensitivity of the detection system, with the non-inverting amplifier configuration allowing for amplification of the received ultrasonic signal. The subsequent low-pass filter ensures that the output voltage is smoothed, reducing noise and providing a cleaner DC signal for further processing.

The comparator configuration in U2b is essential for establishing a threshold level that determines when an obstacle is detected. By adjusting the sensitivity via the potentiometer VR2, the system can be calibrated to respond to different types of obstacles or varying signal conditions, enhancing its versatility.

The integration of the 2N2222 transistor as an inverter allows for simple interfacing with the Handy Board's logic levels, facilitating seamless communication between the detection circuit and the robot's control system. The LED indicator serves as a visual confirmation of obstacle detection, providing immediate feedback for debugging and operational verification.

Overall, this circuit design effectively combines ultrasonic sensing technology with robust signal processing techniques, enabling reliable obstacle detection in robotic systems.The robot requires means of detecting an obstacle (or another robot) without making physical contact. This allows the robot to decide whether to avoid or to confront and investigate the obstacle depending on its programming.

This is one solution and the design of obstacle detection circuit. Here`s the figure of the circuit; In this circuit, ultras onic transducers were chosen for this because they are more reliable and have a greater range than IR sensors (effectiveness of IR sensors varies with ambient light level). The IC U1 is a 555 timer in astable configuration to oscillate at 40 KHz. Instead of using exact values for the two resistors that is placed between pin 6 and 7, a 10K ohm potentiometer (VR1) was used.

This also allows for some fine tuning of the output frequency. The output (pin 3) is then attached to a 40 KHz ultrasonic transmitter (UTR1). The receiving circuit is a dual LM358N (U2) op-amp. An ultrasonic receiver (UTR2) is connected to pin 3, the non-inverting input of U2a which is a non-inverting amplifier with a gain of 220. The output of U2a is put through a low pass filter via D1, C3 and R4 to produce a somewhat stable DC voltage.

This DC voltage is fed into the non-inverting input of U2b configured as a non-inverting comparator. Sensitivity of U2b is controlled by VR2 to set the threshold trigger value. The output of U2b is connected through R5 to the base of a bipolar 2N2222 transistor (Q1) acting as an inverter with a LED (LED1) to indicate if an obstacle has been detected. Finally, the collector of Q1 goes to the Handy Board`s digital port (Handy Board uses inverted logic levels, 0V is a logic 1 and +5V is a logic 0).

🔗 External reference

The described obstacle detection circuit employs ultrasonic technology to facilitate non-contact sensing capabilities in robotic applications. The choice of a 555 timer in astable mode for generating a 40 kHz signal is critical, as this frequency is optimal for ultrasonic transmission and reception, allowing for effective detection of obstacles at varying distances. The inclusion of a potentiometer for frequency adjustment provides flexibility in tuning the system to account for environmental factors and specific application requirements.

The use of the LM358N op-amp in the receiving circuit enhances the sensitivity of the detection system, with the non-inverting amplifier configuration allowing for amplification of the received ultrasonic signal. The subsequent low-pass filter ensures that the output voltage is smoothed, reducing noise and providing a cleaner DC signal for further processing.

The comparator configuration in U2b is essential for establishing a threshold level that determines when an obstacle is detected. By adjusting the sensitivity via the potentiometer VR2, the system can be calibrated to respond to different types of obstacles or varying signal conditions, enhancing its versatility.

The integration of the 2N2222 transistor as an inverter allows for simple interfacing with the Handy Board's logic levels, facilitating seamless communication between the detection circuit and the robot's control system. The LED indicator serves as a visual confirmation of obstacle detection, providing immediate feedback for debugging and operational verification.

Overall, this circuit design effectively combines ultrasonic sensing technology with robust signal processing techniques, enabling reliable obstacle detection in robotic systems.The robot requires means of detecting an obstacle (or another robot) without making physical contact. This allows the robot to decide whether to avoid or to confront and investigate the obstacle depending on its programming.

This is one solution and the design of obstacle detection circuit. Here`s the figure of the circuit; In this circuit, ultras onic transducers were chosen for this because they are more reliable and have a greater range than IR sensors (effectiveness of IR sensors varies with ambient light level). The IC U1 is a 555 timer in astable configuration to oscillate at 40 KHz. Instead of using exact values for the two resistors that is placed between pin 6 and 7, a 10K ohm potentiometer (VR1) was used.

This also allows for some fine tuning of the output frequency. The output (pin 3) is then attached to a 40 KHz ultrasonic transmitter (UTR1). The receiving circuit is a dual LM358N (U2) op-amp. An ultrasonic receiver (UTR2) is connected to pin 3, the non-inverting input of U2a which is a non-inverting amplifier with a gain of 220. The output of U2a is put through a low pass filter via D1, C3 and R4 to produce a somewhat stable DC voltage.

This DC voltage is fed into the non-inverting input of U2b configured as a non-inverting comparator. Sensitivity of U2b is controlled by VR2 to set the threshold trigger value. The output of U2b is connected through R5 to the base of a bipolar 2N2222 transistor (Q1) acting as an inverter with a LED (LED1) to indicate if an obstacle has been detected. Finally, the collector of Q1 goes to the Handy Board`s digital port (Handy Board uses inverted logic levels, 0V is a logic 1 and +5V is a logic 0).

🔗 External reference