plate reverb restoration

Jim enhanced the original EMT 140 design by selecting a plate material that produces a brighter sound, integrating modern electronics, and incorporating higher gain pickups. He also offered a significant discount compared to the inflated prices of the German EMT units. After transporting the unit down the stairs, it was placed under the stairwell outside the recording space. The decision was made to omit the 3/4" plywood box intended for the unit due to space and weight constraints. Although the box provides acoustic isolation, the current location already offers sufficient isolation. The unit weighs approximately 350 pounds when housed in its case. Notably, this is a prototype created by Jim before entering the professional market. Unit #1B is functionally similar to a production model. However, years of neglect necessitated repairs to restore it for operational use. This documentation outlines the ongoing efforts to revive this echo chamber for studio applications. The Ecoplate requires a power amplifier for the driver mounted on the plate and two preamps to elevate the pickups' output to line level. Upon arrival at the studio, appropriate connectors were attached to the bare wires from the speaker and preamps. A temporary power amplifier was constructed using a Hafler P3000, rated at 150W per channel, with the gain set low enough to power the driver adequately (using a pre-recorded vocal track). The output from one pickup was routed to an Avalon U5 direct box, which, despite needing to boost the DI output, proved to be the most effective option available. Due to the limited availability of DIs, the plate was operated with only one pickup, resulting in half of its intended output. A previously recorded vocal track, captured with an Electro-Voice V-2A ribbon microphone through the Ampex MX-10, was selected for testing. An equalizer was applied to mimic the frequency response curve expected from the driver amplifier. The signal was sent through the amplifier to the plate (without the damping plate initially) and recorded. The output was then captured through the MOTU interface. The results were subpar, with noticeable hum and a high noise floor. Subsequent adjustments included boosting the track gain in Cakewalk by 12dB, and applying a gate to reduce hum in the mix. These tests indicated potential for improvement, as the Ecoplate is designed to produce clean audio rather than a muted, noisy output. The Ecoplate features a damping plate mechanism that allows for adjustment of the reverb decay time between 2 to 5 seconds by positioning the damping plate closer to or farther from the echo plate, which is made of stainless steel. However, the original damping plate was flawed, utilizing fiberglass insulation on a 3/4" plywood sheet, which did not effectively absorb sound. A new damping plate was constructed based on plans provided by Jim.

The Ecoplate echo chamber operates on the principle of mechanical reverberation, utilizing a stainless steel echo plate that vibrates in response to sound waves. The driver, mounted centrally on the plate, converts electrical signals into mechanical vibrations, generating sound waves that resonate through the plate material. The integration of higher gain pickups allows for improved sensitivity and a broader frequency response, enhancing the overall audio quality.

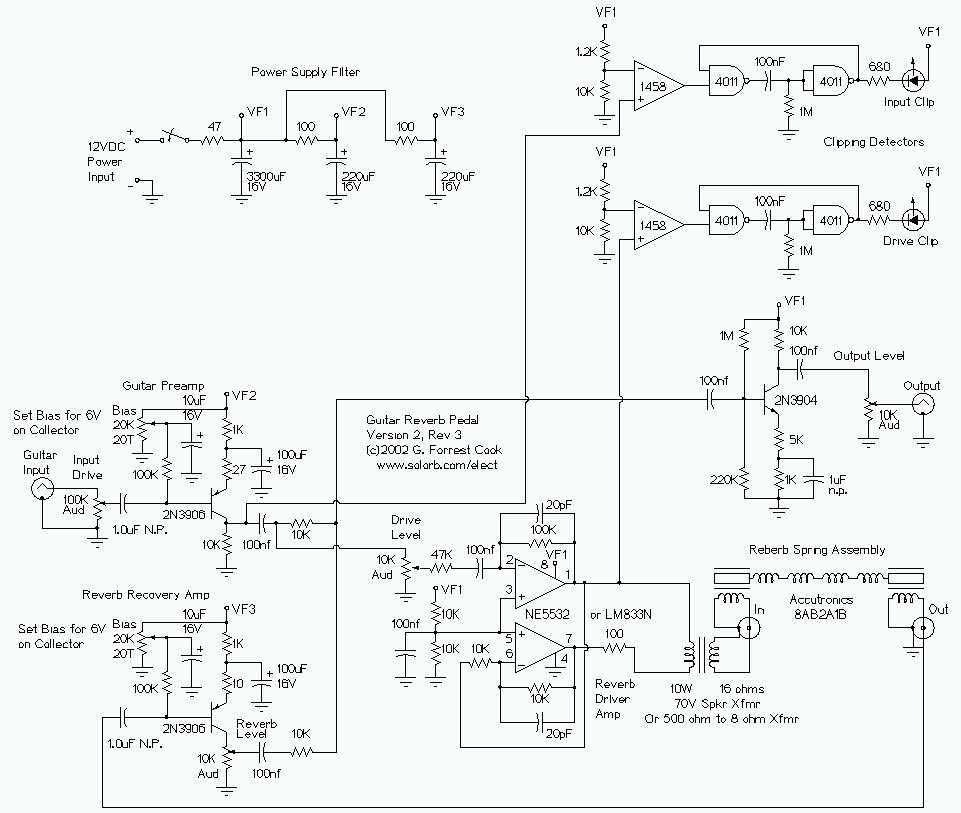

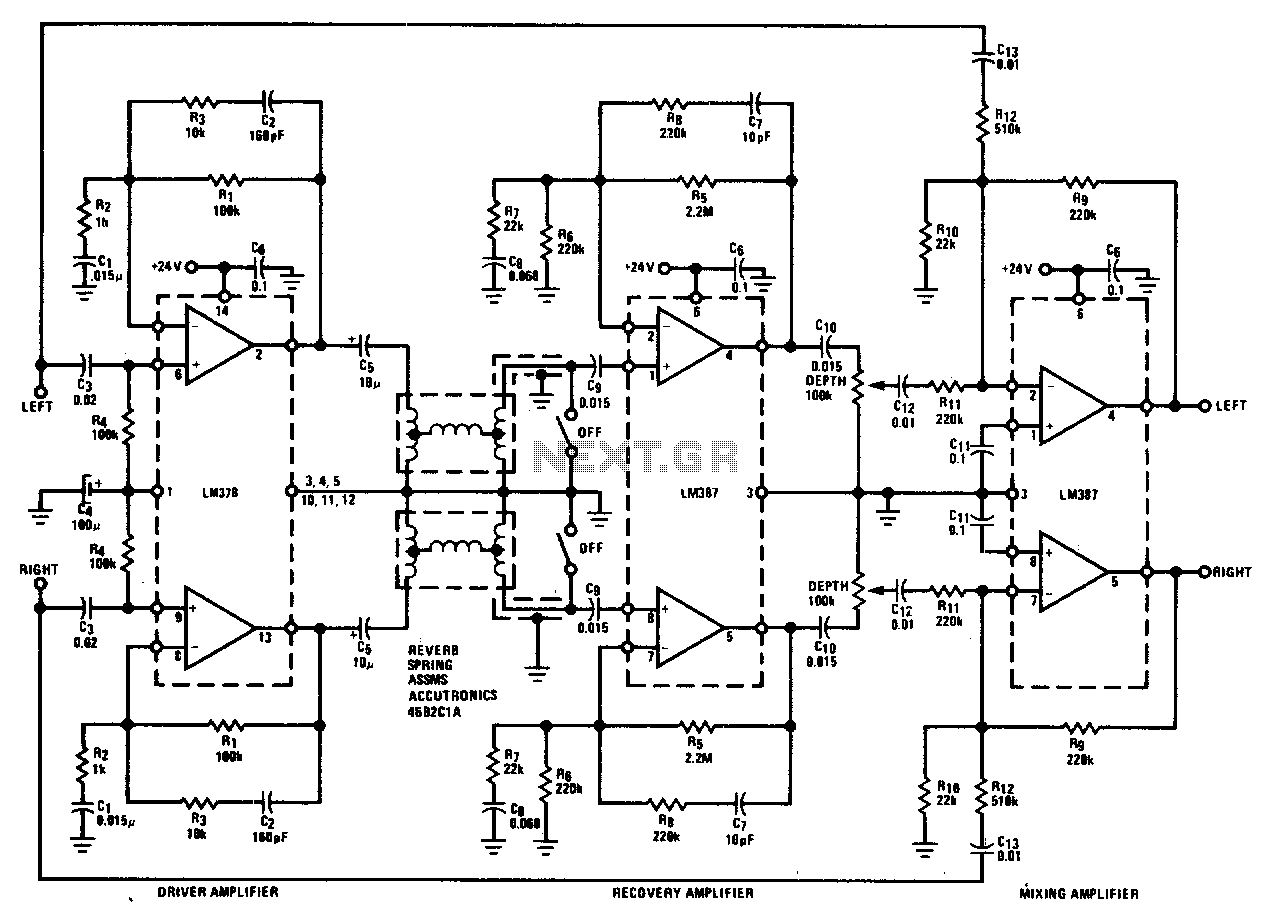

To facilitate the restoration and optimal performance of the Ecoplate, the following components are essential: a power amplifier capable of driving the plate's driver without distortion, and two preamps to amplify the signals from the pickups to line level. The choice of preamps is critical; they must provide sufficient gain while maintaining audio fidelity.

The construction of a new damping plate is imperative for achieving the desired acoustic characteristics. The damping plate's design should incorporate effective sound-absorbing materials to enhance the decay time control and prevent unwanted resonances that could muddy the output sound. Adjustments to the damping plate's positioning will allow for fine-tuning of the reverb effect, enabling a range of decay times suitable for various recording applications.

In summary, the restoration of the Ecoplate involves meticulous attention to the electronic components and acoustic design, ensuring that the unit can deliver high-quality reverberation suitable for professional studio use. Continued testing and adjustments will be necessary to achieve the intended audio performance and rectify any issues related to noise and sound quality.Jim took the original EMT 140 design and improved it by using a plate material with a brighter sound, adding modern electronics and higher gain pickups, and providing a substantial discount on the inflated price that plagued the German EMT units. After lugging it down the stairs, we located it under the stairwell outside our recording space. We decided to forego the 3/4" plywood box the unit is meant to go inside, for space and weight considerations. The acoustical isolation afforded by the box is nice, but because it is located outside our recording space it is well isolated as-is. Not to mention, it tips the scales at around 350 pounds when it`s cased. Interestingly, this unit is a prototype Jim built before going to market professionally. Unit #1B is for all practical purposes identical to a production unit. However, years of pillaging and disuse meant that it needed some work to put it back in service. This site attempts to document my efforts in bringing this echo chamber back to life for use in my studio.

This is an ongoing effort, and is not yet completed. The Ecoplate needs a power amplifier for the driver mounted in the middle of the plate, and two preamps to get the pickups` output up to line level. When the unit got to the studio, I first wired on some appropriate connectors to the bare wires from the speaker and preamps.

I then jury-rigged a power amp using a much too powerful Hafler P3000 150W per channel amplifier. I turned the gain almost completely down on the amp, and it appeared to power the driver at an appropriate level (using a pre-recorded vocal track described below). I then took one pickup`s output and sent it to my Avalon U5 direct box. I had to crank the DI output, but after trying it through two different microphone preamps to no avail (Sytek MPX-4Aii and Ampex MX-10), it was the best of what I had.

Not to mention, the only unit with a Hi-Z input as required. I only have one of these DIs, so I settled on operating the plate with only one pickup - thus half its intended output. I picked a vocal track that had been previously recorded through the Ampex MX-10 using an Electro-Voice V-2A ribbon microphone.

I applied an equalizer on the track to mimic the frequency response curve the driver amp is meant to employ. I sent this out through the amp to the plate (with no damping plate at this point - see below) and recorded the output.

I then patched the DI into my MOTU to record the resulting reverb track. The result was. not that great. This clip contains 3 sections. The first is the dry, pre-recorded vocal. The second is the Ecoplate track. The third is a mix of the two. Notice the hum in the reverb track - an astonishing noise floor. Subsequently, I boosted the track gain in Cakewalk by 12dB to get it to what you hear in the 2nd and 3rd sections. The third section is a mix intended to show what it might sound like on its own someday. I put a gate on the reverb track to cut out some of the hum for this section. These tests demonstrate there is potential for improvement. The Ecoplate is supposed to shell out clean audio, not sound so muted and noisy. Time to hit the workbench. The Ecoplate uses a damping plate mechanism to adjust the decay time of the reverb. The damping plate can be adjusted to provide 2-5 seconds of decay. Decay rate is adjusted by moving the damping plate closer to or farther away from the echo plate. The damping plate is mounted in parallel to the echo plate (made of stainless steel). Unfortunately, the included damping plate (figure a below) is of an earlier, flawed variety. It uses fiberglass insulation mounted to a 3/4" plywood sheet, which does not properly absorb sound. Using plans provided by Jim, I built the new damping plate 🔗 External reference

The Ecoplate echo chamber operates on the principle of mechanical reverberation, utilizing a stainless steel echo plate that vibrates in response to sound waves. The driver, mounted centrally on the plate, converts electrical signals into mechanical vibrations, generating sound waves that resonate through the plate material. The integration of higher gain pickups allows for improved sensitivity and a broader frequency response, enhancing the overall audio quality.

To facilitate the restoration and optimal performance of the Ecoplate, the following components are essential: a power amplifier capable of driving the plate's driver without distortion, and two preamps to amplify the signals from the pickups to line level. The choice of preamps is critical; they must provide sufficient gain while maintaining audio fidelity.

The construction of a new damping plate is imperative for achieving the desired acoustic characteristics. The damping plate's design should incorporate effective sound-absorbing materials to enhance the decay time control and prevent unwanted resonances that could muddy the output sound. Adjustments to the damping plate's positioning will allow for fine-tuning of the reverb effect, enabling a range of decay times suitable for various recording applications.

In summary, the restoration of the Ecoplate involves meticulous attention to the electronic components and acoustic design, ensuring that the unit can deliver high-quality reverberation suitable for professional studio use. Continued testing and adjustments will be necessary to achieve the intended audio performance and rectify any issues related to noise and sound quality.Jim took the original EMT 140 design and improved it by using a plate material with a brighter sound, adding modern electronics and higher gain pickups, and providing a substantial discount on the inflated price that plagued the German EMT units. After lugging it down the stairs, we located it under the stairwell outside our recording space. We decided to forego the 3/4" plywood box the unit is meant to go inside, for space and weight considerations. The acoustical isolation afforded by the box is nice, but because it is located outside our recording space it is well isolated as-is. Not to mention, it tips the scales at around 350 pounds when it`s cased. Interestingly, this unit is a prototype Jim built before going to market professionally. Unit #1B is for all practical purposes identical to a production unit. However, years of pillaging and disuse meant that it needed some work to put it back in service. This site attempts to document my efforts in bringing this echo chamber back to life for use in my studio.

This is an ongoing effort, and is not yet completed. The Ecoplate needs a power amplifier for the driver mounted in the middle of the plate, and two preamps to get the pickups` output up to line level. When the unit got to the studio, I first wired on some appropriate connectors to the bare wires from the speaker and preamps.

I then jury-rigged a power amp using a much too powerful Hafler P3000 150W per channel amplifier. I turned the gain almost completely down on the amp, and it appeared to power the driver at an appropriate level (using a pre-recorded vocal track described below). I then took one pickup`s output and sent it to my Avalon U5 direct box. I had to crank the DI output, but after trying it through two different microphone preamps to no avail (Sytek MPX-4Aii and Ampex MX-10), it was the best of what I had.

Not to mention, the only unit with a Hi-Z input as required. I only have one of these DIs, so I settled on operating the plate with only one pickup - thus half its intended output. I picked a vocal track that had been previously recorded through the Ampex MX-10 using an Electro-Voice V-2A ribbon microphone.

I applied an equalizer on the track to mimic the frequency response curve the driver amp is meant to employ. I sent this out through the amp to the plate (with no damping plate at this point - see below) and recorded the output.

I then patched the DI into my MOTU to record the resulting reverb track. The result was. not that great. This clip contains 3 sections. The first is the dry, pre-recorded vocal. The second is the Ecoplate track. The third is a mix of the two. Notice the hum in the reverb track - an astonishing noise floor. Subsequently, I boosted the track gain in Cakewalk by 12dB to get it to what you hear in the 2nd and 3rd sections. The third section is a mix intended to show what it might sound like on its own someday. I put a gate on the reverb track to cut out some of the hum for this section. These tests demonstrate there is potential for improvement. The Ecoplate is supposed to shell out clean audio, not sound so muted and noisy. Time to hit the workbench. The Ecoplate uses a damping plate mechanism to adjust the decay time of the reverb. The damping plate can be adjusted to provide 2-5 seconds of decay. Decay rate is adjusted by moving the damping plate closer to or farther away from the echo plate. The damping plate is mounted in parallel to the echo plate (made of stainless steel). Unfortunately, the included damping plate (figure a below) is of an earlier, flawed variety. It uses fiberglass insulation mounted to a 3/4" plywood sheet, which does not properly absorb sound. Using plans provided by Jim, I built the new damping plate 🔗 External reference