Protect IGBTs by Sensing Current Using Optical Isolation Amplifiers

Insulated-gate bipolar transistors (IGBTs) require comprehensive protection to prevent damage and failures due to conditions such as short circuits, overloads, and overvoltages. This protection is essential for ensuring safe and stable operation of power converters in applications including motor drives and solar and wind power generation systems. To detect over-current and overload conditions, isolation amplifiers featuring fast response or rapid fault feedback can be utilized on the output phases and the DC bus. A typical block diagram of a power converter in an AC motor drive is illustrated. It consists of an inverter that converts the DC bus voltage into AC power at a variable frequency to drive the motor. IGBTs are costly power switches that form the core of the inverter. These power devices must operate at high frequencies and withstand high voltages. Isolation amplifiers, such as the ACPL-C79A, function alongside shunt resistors to deliver accurate current measurements in power converters, even amidst significant switching noise. When paired with a resistive divider, isolation amplifiers serve as precision voltage sensors to monitor the DC bus voltage. The current and voltage data from the isolation amplifiers are gathered by the microcontroller, which utilizes this information to calculate the feedback values and output signals necessary for effective control and fault management in the power converters. Given that IGBTs represent the most expensive components in an inverter, it is prudent to provide extensive protection to prevent their damage. The Avago isolation amplifiers enable rapid detection of fault conditions, and the algorithms executed by the microcontroller can avert these faults from causing IGBT failures. Furthermore, the optical isolation provided by the isolation amplifiers protects the microcontroller from being overloaded by fault conditions, thereby preventing its failure. Nevertheless, IGBT protection must be cost-effective, as the market demands adequate protection from fault conditions without significantly increasing the overall cost of the motor drive system. To address this need, IGBT gate drivers and current sensors with integrated protection features have been developed to perform essential fault detection alongside their driving and sensing roles. These innovations offer a cost-effective solution for implementing IGBT protection, negating the need for separate detection and feedback components. Further details on the protection features integrated with the Avago gate drivers and their application in IGBT protection can be found in referenced materials. The remainder of this document will concentrate on various fault protection functions that can be implemented using current and voltage sensors.

Insulated-gate bipolar transistors (IGBTs) are critical components in power electronics, particularly in applications like motor drives and renewable energy systems. Their vulnerability to electrical faults necessitates robust protective measures to enhance reliability and performance. The primary threats to IGBT integrity include short circuits, overloads, and overvoltages, which can lead to catastrophic failures if not adequately managed.

To address these challenges, the implementation of isolation amplifiers is essential. These devices are capable of providing rapid feedback on fault conditions, allowing for immediate corrective actions. The integration of isolation amplifiers with shunt resistors creates a reliable method for measuring current, even in electrically noisy environments typical of high-frequency switching applications. The ACPL-C79A is an example of such an isolation amplifier, designed to maintain accuracy in current sensing while isolating the measuring instrument from high voltages.

In a typical power converter circuit, the inverter plays a pivotal role by converting the DC bus voltage into variable frequency AC power, which is essential for motor operation. The inverter’s performance heavily relies on the IGBTs, which must be capable of handling high-frequency operations and significant voltage levels. The use of resistive dividers in conjunction with isolation amplifiers enables precise monitoring of the DC bus voltage, further enhancing the system's reliability.

The microcontroller serves as the central processing unit, gathering current and voltage data from the isolation amplifiers. This data is critical for calculating feedback values that facilitate effective control strategies and fault management. By employing sophisticated algorithms, the microcontroller can predict potential faults and activate protective measures before damage occurs to the IGBTs.

Cost efficiency is a significant consideration in the design of IGBT protection systems. The introduction of gate drivers, such as the ACPL-332J, and current sensors with built-in protection features streamlines the fault detection process. These components not only drive the IGBTs but also incorporate essential fault detection capabilities, minimizing the need for additional hardware and reducing overall system costs.

In summary, the integration of isolation amplifiers, microcontrollers, and advanced gate drivers forms a comprehensive protection strategy for IGBTs in power converters. This approach ensures that the IGBTs operate safely within their specified limits, enhancing the reliability and efficiency of motor drives and renewable energy systems. The ongoing evolution of these protective technologies will continue to address the market's demand for cost-effective solutions while maintaining high-performance standards.Insulated-gate bipolar transistors (IGBTs) require full protection to avoid damage and failures resulting from conditions such as short circuits, overloads and overvoltages. The protection is key to ensuring safe and stable power-converter operations in applications such as motor drives and solar and wind power generation systems.

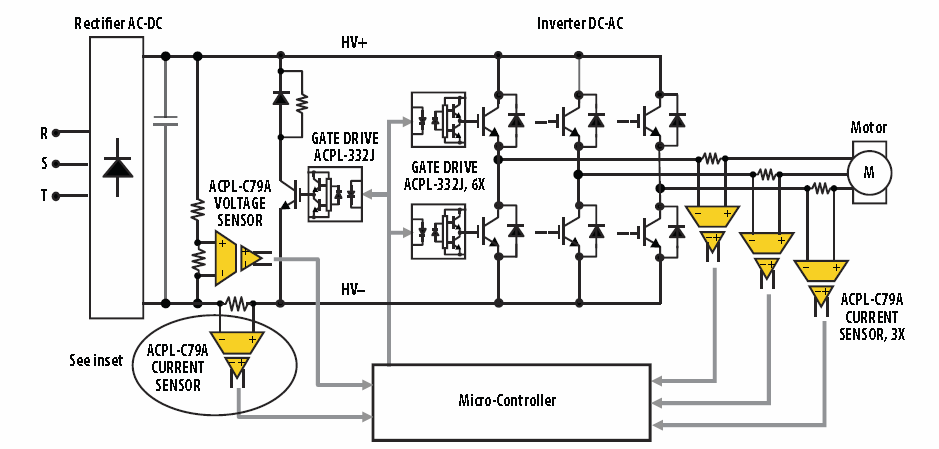

To detect over-current and overload conditions, isolation amplifiers featuring fast response or fast fault feedback can be used on the output phases and the DC bus. Figure 1a shows a typical block diagram of a power converter in an AC motor drive. It consists of an inverter that converts the DC bus voltage to AC power at a variable frequency to drive the motor. IGBTs are expensive power switches that form the heart of the inverter. These power devices must operate at a high frequency and must be able to withstand high voltages. Isolation amplifiers (iso-amps), such as the ACPL-C79A 1 shown in Figure 1b, work in conjunction with shunt resistors to provide accurate current measurements in power converters even in the presence of high switching noise.

When used with a resistive divider, iso-amps work as precision voltage sensors to monitor the DC bus voltage. The current and voltage information from the iso-amps are collected by the microcontroller, which uses the data to calculate the feedback values and output signals needed to provide effective control and fault management in the power converters.

In an inverter, the IGBTs are the most costly components and it thus makes sense to provide as much protection as possible to protect them from damage. The Avago iso-amps provide quick sensing of fault conditions and the algorithms the microcontroller executes can prevent the fault conditions from causing the IGBTs to fail.

Additionally, the optical isolation in the iso-amps prevents the fault conditions from overloading the microcontroller and causing it to fail. However, the IGBT protection must be cost effective the market continues to demand sufficient IGBT protection from fault conditions at a cost that does not significantly affect the total cost of the motor drive system.

To meet this demand, IGBT gate drivers (such as the ACPL-332J 1 ) and current sensors with protection features have been introduced to carry out essential fault detection in addition to their driving and sensing functions. These products provide a cost-effective scheme to implement IGBT protection and eliminate the need for separate detection and feedback components.

Refer to References[2, 3] for details of those protection features integrated with the Avago gate drivers and how to use those features in IGBT protection applications. The remainder of this paper will focus on some of the fault protection functions that can be implemented with current/voltage sensors as listed in Table 1.

🔗 External reference

Insulated-gate bipolar transistors (IGBTs) are critical components in power electronics, particularly in applications like motor drives and renewable energy systems. Their vulnerability to electrical faults necessitates robust protective measures to enhance reliability and performance. The primary threats to IGBT integrity include short circuits, overloads, and overvoltages, which can lead to catastrophic failures if not adequately managed.

To address these challenges, the implementation of isolation amplifiers is essential. These devices are capable of providing rapid feedback on fault conditions, allowing for immediate corrective actions. The integration of isolation amplifiers with shunt resistors creates a reliable method for measuring current, even in electrically noisy environments typical of high-frequency switching applications. The ACPL-C79A is an example of such an isolation amplifier, designed to maintain accuracy in current sensing while isolating the measuring instrument from high voltages.

In a typical power converter circuit, the inverter plays a pivotal role by converting the DC bus voltage into variable frequency AC power, which is essential for motor operation. The inverter’s performance heavily relies on the IGBTs, which must be capable of handling high-frequency operations and significant voltage levels. The use of resistive dividers in conjunction with isolation amplifiers enables precise monitoring of the DC bus voltage, further enhancing the system's reliability.

The microcontroller serves as the central processing unit, gathering current and voltage data from the isolation amplifiers. This data is critical for calculating feedback values that facilitate effective control strategies and fault management. By employing sophisticated algorithms, the microcontroller can predict potential faults and activate protective measures before damage occurs to the IGBTs.

Cost efficiency is a significant consideration in the design of IGBT protection systems. The introduction of gate drivers, such as the ACPL-332J, and current sensors with built-in protection features streamlines the fault detection process. These components not only drive the IGBTs but also incorporate essential fault detection capabilities, minimizing the need for additional hardware and reducing overall system costs.

In summary, the integration of isolation amplifiers, microcontrollers, and advanced gate drivers forms a comprehensive protection strategy for IGBTs in power converters. This approach ensures that the IGBTs operate safely within their specified limits, enhancing the reliability and efficiency of motor drives and renewable energy systems. The ongoing evolution of these protective technologies will continue to address the market's demand for cost-effective solutions while maintaining high-performance standards.Insulated-gate bipolar transistors (IGBTs) require full protection to avoid damage and failures resulting from conditions such as short circuits, overloads and overvoltages. The protection is key to ensuring safe and stable power-converter operations in applications such as motor drives and solar and wind power generation systems.

To detect over-current and overload conditions, isolation amplifiers featuring fast response or fast fault feedback can be used on the output phases and the DC bus. Figure 1a shows a typical block diagram of a power converter in an AC motor drive. It consists of an inverter that converts the DC bus voltage to AC power at a variable frequency to drive the motor. IGBTs are expensive power switches that form the heart of the inverter. These power devices must operate at a high frequency and must be able to withstand high voltages. Isolation amplifiers (iso-amps), such as the ACPL-C79A 1 shown in Figure 1b, work in conjunction with shunt resistors to provide accurate current measurements in power converters even in the presence of high switching noise.

When used with a resistive divider, iso-amps work as precision voltage sensors to monitor the DC bus voltage. The current and voltage information from the iso-amps are collected by the microcontroller, which uses the data to calculate the feedback values and output signals needed to provide effective control and fault management in the power converters.

In an inverter, the IGBTs are the most costly components and it thus makes sense to provide as much protection as possible to protect them from damage. The Avago iso-amps provide quick sensing of fault conditions and the algorithms the microcontroller executes can prevent the fault conditions from causing the IGBTs to fail.

Additionally, the optical isolation in the iso-amps prevents the fault conditions from overloading the microcontroller and causing it to fail. However, the IGBT protection must be cost effective the market continues to demand sufficient IGBT protection from fault conditions at a cost that does not significantly affect the total cost of the motor drive system.

To meet this demand, IGBT gate drivers (such as the ACPL-332J 1 ) and current sensors with protection features have been introduced to carry out essential fault detection in addition to their driving and sensing functions. These products provide a cost-effective scheme to implement IGBT protection and eliminate the need for separate detection and feedback components.

Refer to References[2, 3] for details of those protection features integrated with the Avago gate drivers and how to use those features in IGBT protection applications. The remainder of this paper will focus on some of the fault protection functions that can be implemented with current/voltage sensors as listed in Table 1.

🔗 External reference