PWM fan controller with PIC 12F675

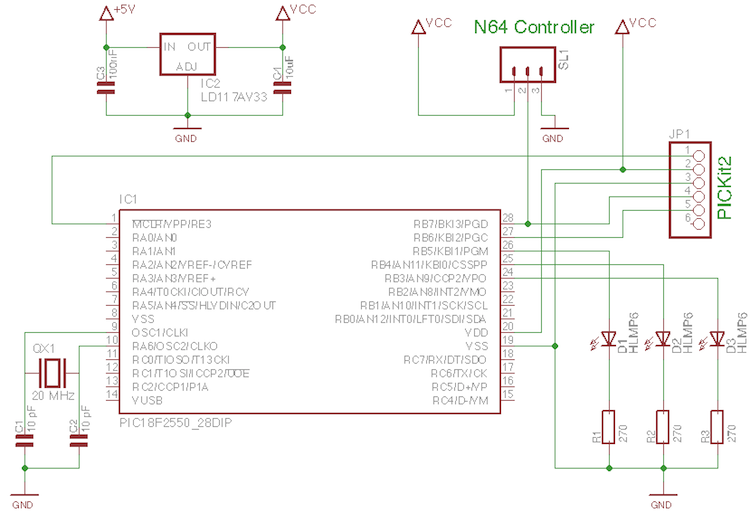

The temperature sensor U2 needs to be located next to the item being monitored. As the temperature increases the motor duty cycle will increase. D1 and R2 are optical components, they only need to be installed for a visual indication of the current duty cycle. Q1 is a 2N4001 NPN transistor. Resistors are all 1/4 Watt. D1 is a blue LED.

The circuit described involves a temperature sensing and control mechanism utilizing a temperature sensor (U2) placed in close proximity to the monitored item. The sensor's role is to detect temperature changes, which subsequently modulate the duty cycle of a motor. As the temperature rises, the control circuit will increase the duty cycle, allowing for proportional control over the motor's speed or power output.

The optical components D1 and R2 serve a dual purpose: providing visual feedback regarding the current duty cycle and enhancing user interaction with the circuit. D1, a blue LED, will illuminate in accordance with the duty cycle, allowing users to easily gauge the operational state of the motor. R2, likely a current-limiting resistor, ensures that the LED operates within its specified current rating, preventing damage.

The circuit utilizes Q1, a 2N4001 NPN transistor, as a switching element. This transistor will act as an interface between the control signal from the temperature sensor and the motor's power supply. When the temperature exceeds a predetermined threshold, the sensor activates Q1, allowing current to flow through the motor circuit, thereby increasing the motor's duty cycle. The choice of a 2N4001 transistor suggests that the circuit is designed for moderate power applications, given its voltage and current ratings.

All resistors in the circuit are specified as 1/4 Watt, indicating that they are suitable for low-power applications. This specification is critical for ensuring that the components can handle the power dissipation without overheating. Proper selection of resistor values will be necessary to fine-tune the performance of the LED and the transistor's switching characteristics.

Overall, this circuit design integrates temperature sensing with motor control and visual indication, creating an efficient and user-friendly monitoring system. Careful attention to component placement, power ratings, and circuit connections will be essential for optimal performance and reliability.The temperature sensor U2 needs to be located next to the item being monitored. As the temperature increases the motor duty cycle will increase. D1 and R2 are optical components, they only need to be installed for a visual indication of the current duty cycle. Q1 is a 2N4001 NPN transistor. Resistors are all 1/4 Watt. D1 is a blue LED. 🔗 External reference

The circuit described involves a temperature sensing and control mechanism utilizing a temperature sensor (U2) placed in close proximity to the monitored item. The sensor's role is to detect temperature changes, which subsequently modulate the duty cycle of a motor. As the temperature rises, the control circuit will increase the duty cycle, allowing for proportional control over the motor's speed or power output.

The optical components D1 and R2 serve a dual purpose: providing visual feedback regarding the current duty cycle and enhancing user interaction with the circuit. D1, a blue LED, will illuminate in accordance with the duty cycle, allowing users to easily gauge the operational state of the motor. R2, likely a current-limiting resistor, ensures that the LED operates within its specified current rating, preventing damage.

The circuit utilizes Q1, a 2N4001 NPN transistor, as a switching element. This transistor will act as an interface between the control signal from the temperature sensor and the motor's power supply. When the temperature exceeds a predetermined threshold, the sensor activates Q1, allowing current to flow through the motor circuit, thereby increasing the motor's duty cycle. The choice of a 2N4001 transistor suggests that the circuit is designed for moderate power applications, given its voltage and current ratings.

All resistors in the circuit are specified as 1/4 Watt, indicating that they are suitable for low-power applications. This specification is critical for ensuring that the components can handle the power dissipation without overheating. Proper selection of resistor values will be necessary to fine-tune the performance of the LED and the transistor's switching characteristics.

Overall, this circuit design integrates temperature sensing with motor control and visual indication, creating an efficient and user-friendly monitoring system. Careful attention to component placement, power ratings, and circuit connections will be essential for optimal performance and reliability.The temperature sensor U2 needs to be located next to the item being monitored. As the temperature increases the motor duty cycle will increase. D1 and R2 are optical components, they only need to be installed for a visual indication of the current duty cycle. Q1 is a 2N4001 NPN transistor. Resistors are all 1/4 Watt. D1 is a blue LED. 🔗 External reference