Recovery Node

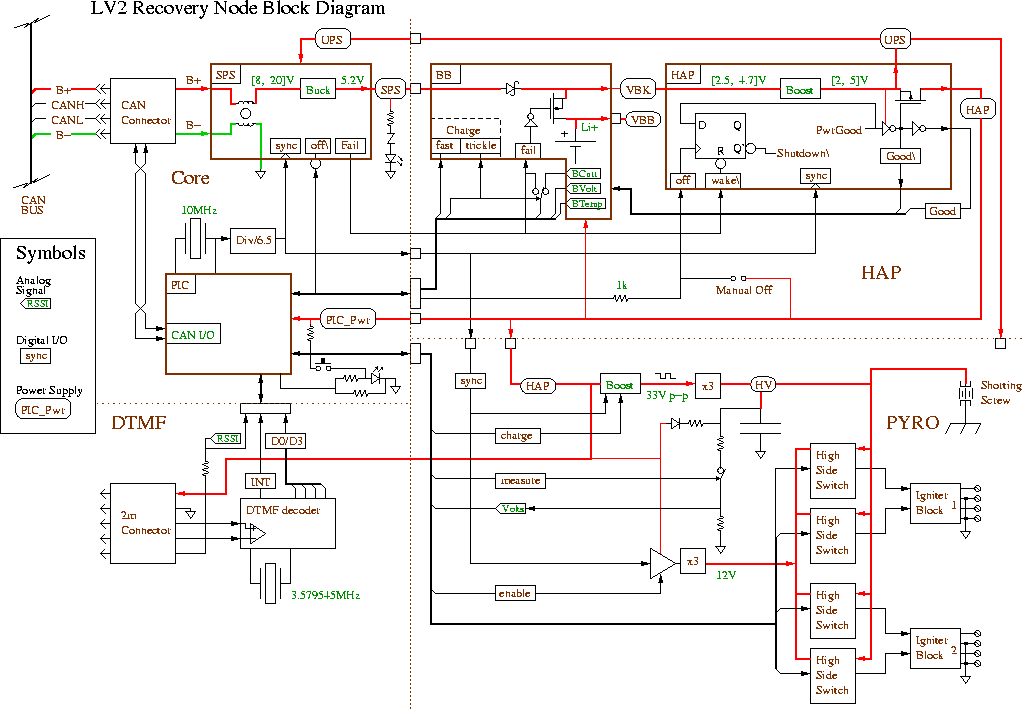

The recovery node is the pyrotechnic controller board designed for LV2. LV2 employs two different parachutes during its descent. The drogue chute deploys first; it is a small parachute that stabilizes the rocket while allowing it to descend at a relatively high speed to minimize drift due to wind. This is crucial for ensuring the rocket lands close to the launch point. However, the descent rate with the drogue chute is too rapid for a safe landing, so approximately 500 meters above ground level, the drogue chute deploys the larger main parachute. The parachute deployment is accomplished using pyrotechnic actuators, which are activated by electric matches (specifically, Oxral electric matches in LV2). The electric match heads are similar in size to standard kitchen match heads and burn with slightly more intensity, with an electrical firing energy threshold of about 2 mJ. The primary objectives of the recovery system are reliability and safety, as parachute failure could result in the total destruction of the vehicle. Additionally, the pyrotechnic actuators pose potential risks to personnel. To mitigate these dangers, the design minimizes the inherent risks associated with the actuators and ensures safe handling to prevent injury from accidental activation. A system of interlocks within the recovery node serves as an additional safety measure. Reliability is achieved through sound design practices, which include reducing the number of critical components, comprehensive testing, and incorporating redundancy for components with lower reliability. These attributes are balanced against the goals of PSAS projects, which aim to minimize complexity, cost, time, weight, and size for each component. Each specification is derived from LV1 hardware, with LV2 incorporating variations. The circuit is organized into sections: CORE, HAP, DTMF, and PYRO. The CORE section includes the CAN bus interface, the main 14V DC power bus, and a two-wire CAN communications interface. It features a PIC18F458 microprocessor and a 1.54MHz switching power supply (SPS) that converts the main bus power to 5 volts. The intention is to reuse the CORE section for all new LV2 CAN nodes. Adjacent to the CORE section is the HAP (High Availability Power supply), which contains another 1.54MHz switching power supply operating in boost mode. This supply generates a 5V output using either the CORE SPS voltage or a single-cell rechargeable lithium battery. The HAP automatically switches to battery power when SPS power fails. It also includes charging, monitoring, and over-voltage protection circuits for the lithium battery. The DTMF section, located at the lower left of the diagram, consists of a single-chip DTMF-tone to 4-bit-parallel I/O decoder, which connects to a 2-meter radio board providing an analog audio signal. The final section, PYRO, contains four 100V igniter switches powered from a common capacitive discharge supply. This high-voltage supply is generated by another 1.54MHz switching power supply that boosts 5V to approximately 33V, which is then processed through a voltage tripler into the discharge capacitor. A separate voltage tripler provides the necessary 12V power supply for the high-side switch drivers. For testing purposes, a disconnectable voltage divider is included to measure the high voltage or, if left connected, to act as a bleeder resistor to expedite the discharge of the high voltage supply.

The recovery node serves as a critical component in the LV2 system, ensuring that the parachute deployment process is executed safely and reliably during descent. The choice of using pyrotechnic actuators and electric matches is driven by the need for precise and immediate deployment of the parachutes, which is essential for achieving a controlled descent. The use of a microcontroller in the CORE section allows for sophisticated control and monitoring capabilities, enabling the system to react quickly to changing conditions during descent.

The HAP section is particularly important for maintaining power availability, as it provides redundancy through the integration of a rechargeable lithium battery. This feature ensures that even in the event of a power failure, the recovery system can continue to function, thus enhancing reliability.

The DTMF section adds an additional layer of functionality by allowing for remote monitoring and control through audio signals, which can be crucial for telemetry and data collection during the recovery phase.

Finally, the PYRO section's design emphasizes safety and reliability, incorporating multiple layers of protection against accidental activation and ensuring that the high-voltage components are well-managed. The use of voltage triplers and capacitive discharge supplies reflects a careful consideration of the electrical requirements necessary to safely ignite the parachute deployment mechanisms.

Overall, the recovery node's design is a testament to the balance between innovation, safety, and reliability, reflecting the rigorous engineering principles that guide the development of aerospace systems.The "recovery node" is the pyrotechnic controller board designed for LV2. LV2 uses two different parachutes during its descent. The drogue chute opens first. The drouge is a small parachute that stabilizes the rocket but allows it to fall at a fairly high speed in order to minimize the distance the rocket drifts with the wind during descent. For r ecovery it is desirable that the rocket land close to the launch point. The descent rate on the drouge chute is too fast for a damage-free landing, so about 500 meters above ground level the drogue chute pulls out the larger main parachute. The deployment of the parachutes is achieved by pyrotechnic actuators. which are in turn initiated by "Electric Matches". (On LV2 these are Oxral electric matches. ) The electric match heads are about the same size as those of ordinary kitchen matches and burn with only slightly more vigor.

Their electrical firing energy threshold is about 2mJ. The two towering goals of the recovery system are reliability and safety. Parachute failure probably means complete destruction of our vehicle. At least as significantly, the pyrotechnic actuators are potentially dangerous to our people. To minimize the danger to people we have firstly designed to minimize the inherent danger in the actuators themselves. Secondly we always handle the devices in such a way as to avoid injury should an accidental activation occur.

Our third line of defense involves a system of interlocks in the recovery node. Reliability is attained by good design. This means good overall design practice, and also minimizing the number of critical components, thorough testing, and some redundancy for low reliability components. These desirable properties are constrained by the typical PSAS projects goals which seek to minimize the complexity, price, time, weight and size of each component.

Each of these specifications descend directly from LV1 hardware but in LV2 each has a slightly different twist. Because it is interesting to understand the reasoning that drives a design, a little history is offered here.

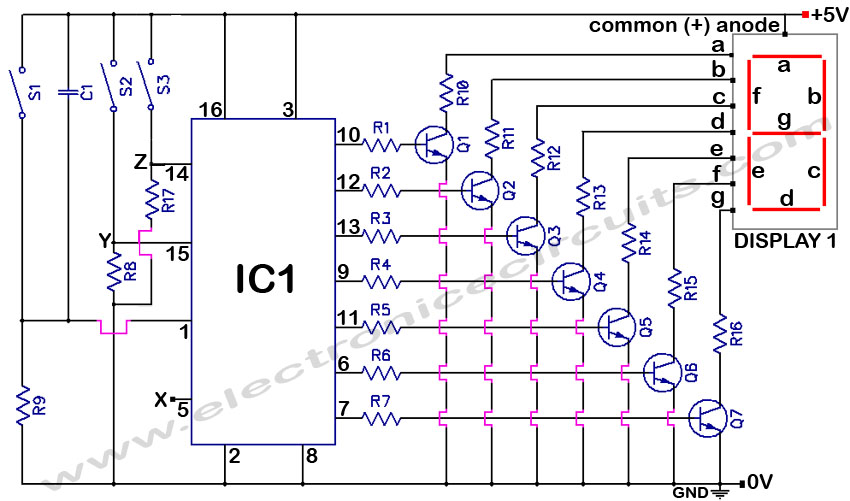

Referring to the block diagram, the circuit is divided into sections, namely the CORE, HAP, DTMF and PYRO sections. The CORE section contains the CAN bus interface which includes the main 14V DC power bus as well as the two wire CAN communications interface.

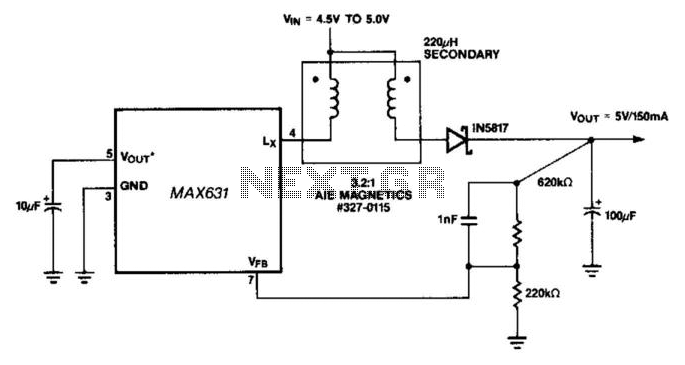

The CORE section has a PIC18F458 microprocessor and a 1. 54MHz switching power supply [SPS] to convert the main bus power down to 5 Volts. The intention is to re-use the CORE section for all new LV2 CAN nodes. To the right of the CORE section is the HAP which stands for High Availability Power supply. The HAP contains another 1. 54MHz switching power supply operating in boost mode. This supply provides a 5V output using either the CORE SPS voltage or a single cell rechargeable lithium battery as input. The HAP automatically switches to battery power when the SPS power fails. In the battery backup [BB] section of the HAP there are charging, monitoring and over voltage protection circuits for the lithium battery At the lower left of the diagram is the DTMF section.

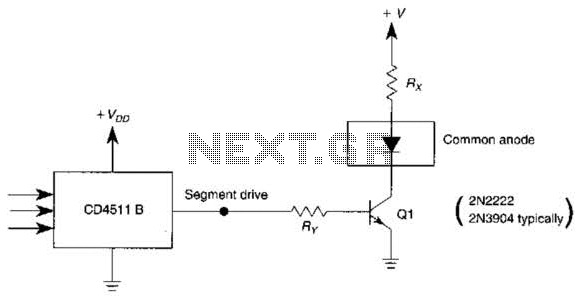

This is basically a single chip DTMF-tone to 4-bit-parallel I/O decoder. The DTMF section connects to the 2 meter [2m] radio board which provides an analog audio signal. PYRO is the recovery node`s final section. It contains four 100V igniter switches powered from a common capacitive discharge supply. The 100V [HV] supply is generated using yet another 1. 54MHz switching power supply boosting 5V to about 33V which is then run through a voltage tripler into the discharge capacitor. There is a separate voltage tripler to provide the required 12V power supply for the high side switch drivers.

For testing there is a disconnectable voltage divider that may be used to measure the HV voltage, or if left connected serves as a bleeder resistor to speed up discharging of the high voltage supply. Lastly there is an externally 🔗 External reference

The recovery node serves as a critical component in the LV2 system, ensuring that the parachute deployment process is executed safely and reliably during descent. The choice of using pyrotechnic actuators and electric matches is driven by the need for precise and immediate deployment of the parachutes, which is essential for achieving a controlled descent. The use of a microcontroller in the CORE section allows for sophisticated control and monitoring capabilities, enabling the system to react quickly to changing conditions during descent.

The HAP section is particularly important for maintaining power availability, as it provides redundancy through the integration of a rechargeable lithium battery. This feature ensures that even in the event of a power failure, the recovery system can continue to function, thus enhancing reliability.

The DTMF section adds an additional layer of functionality by allowing for remote monitoring and control through audio signals, which can be crucial for telemetry and data collection during the recovery phase.

Finally, the PYRO section's design emphasizes safety and reliability, incorporating multiple layers of protection against accidental activation and ensuring that the high-voltage components are well-managed. The use of voltage triplers and capacitive discharge supplies reflects a careful consideration of the electrical requirements necessary to safely ignite the parachute deployment mechanisms.

Overall, the recovery node's design is a testament to the balance between innovation, safety, and reliability, reflecting the rigorous engineering principles that guide the development of aerospace systems.The "recovery node" is the pyrotechnic controller board designed for LV2. LV2 uses two different parachutes during its descent. The drogue chute opens first. The drouge is a small parachute that stabilizes the rocket but allows it to fall at a fairly high speed in order to minimize the distance the rocket drifts with the wind during descent. For r ecovery it is desirable that the rocket land close to the launch point. The descent rate on the drouge chute is too fast for a damage-free landing, so about 500 meters above ground level the drogue chute pulls out the larger main parachute. The deployment of the parachutes is achieved by pyrotechnic actuators. which are in turn initiated by "Electric Matches". (On LV2 these are Oxral electric matches. ) The electric match heads are about the same size as those of ordinary kitchen matches and burn with only slightly more vigor.

Their electrical firing energy threshold is about 2mJ. The two towering goals of the recovery system are reliability and safety. Parachute failure probably means complete destruction of our vehicle. At least as significantly, the pyrotechnic actuators are potentially dangerous to our people. To minimize the danger to people we have firstly designed to minimize the inherent danger in the actuators themselves. Secondly we always handle the devices in such a way as to avoid injury should an accidental activation occur.

Our third line of defense involves a system of interlocks in the recovery node. Reliability is attained by good design. This means good overall design practice, and also minimizing the number of critical components, thorough testing, and some redundancy for low reliability components. These desirable properties are constrained by the typical PSAS projects goals which seek to minimize the complexity, price, time, weight and size of each component.

Each of these specifications descend directly from LV1 hardware but in LV2 each has a slightly different twist. Because it is interesting to understand the reasoning that drives a design, a little history is offered here.

Referring to the block diagram, the circuit is divided into sections, namely the CORE, HAP, DTMF and PYRO sections. The CORE section contains the CAN bus interface which includes the main 14V DC power bus as well as the two wire CAN communications interface.

The CORE section has a PIC18F458 microprocessor and a 1. 54MHz switching power supply [SPS] to convert the main bus power down to 5 Volts. The intention is to re-use the CORE section for all new LV2 CAN nodes. To the right of the CORE section is the HAP which stands for High Availability Power supply. The HAP contains another 1. 54MHz switching power supply operating in boost mode. This supply provides a 5V output using either the CORE SPS voltage or a single cell rechargeable lithium battery as input. The HAP automatically switches to battery power when the SPS power fails. In the battery backup [BB] section of the HAP there are charging, monitoring and over voltage protection circuits for the lithium battery At the lower left of the diagram is the DTMF section.

This is basically a single chip DTMF-tone to 4-bit-parallel I/O decoder. The DTMF section connects to the 2 meter [2m] radio board which provides an analog audio signal. PYRO is the recovery node`s final section. It contains four 100V igniter switches powered from a common capacitive discharge supply. The 100V [HV] supply is generated using yet another 1. 54MHz switching power supply boosting 5V to about 33V which is then run through a voltage tripler into the discharge capacitor. There is a separate voltage tripler to provide the required 12V power supply for the high side switch drivers.

For testing there is a disconnectable voltage divider that may be used to measure the HV voltage, or if left connected serves as a bleeder resistor to speed up discharging of the high voltage supply. Lastly there is an externally 🔗 External reference