Regulated 24 Watt Broad Spectrum LED

This project involves constructing an energy-efficient broad spectrum LED lamp system designed for indoor reflective room lighting. The lamp provides a broad color spectrum that closely resembles natural sunlight compared to fluorescent bulbs and white-only LEDs. The light output is regulated and flicker-free. The system utilizes six different colored LED stars, manufactured by LedEngin, Inc., each rated at 5 watts (nominal). The LED array, along with the associated current regulator, consumes 1 amp at 24VDC (24 Watts). Caution is advised, as staring directly at this lamp while it operates at full power can be dangerously bright. The combined color output of the LEDs yields a pinkish-white hue. The actual power consumption of the LEDs varies, with the white, blue, and green LEDs drawing approximately 4W, while the lower voltage red, orange, and deep red LEDs consume about 3W each. The current regulator maintains consistent brightness and ensures that the LED series string does not exceed 1 amp of current. This project is referred to as "Bold as LED," inspired by the Jimi Hendrix song "Bold as Love," which includes the lyric, "My yellow in this case is not so mellow." The lamp operates as a current loop, comprising the power supply, the LED series string, and a 1 amp current regulator circuit. The LM317K and a 1.2 ohm 5 Watt resistor function as the current regulator, limiting the loop current to 1 Amp, with a constant 1.2V across the resistor during operation. The current regulator ensures the LEDs operate at maximum brightness without risk of burnout. A 100uF electrolytic capacitor bypasses the DC power input, while a 100nF monoblock capacitor bypasses the LM317K input. The LEDs and current regulator circuit are mounted on a 3" x 8" piece of 1/8" aluminum stock. The LM317K regulator and LED heat sinks are bolted directly to the chassis, with heat sink grease applied to the regulator, heat sinks, and the six LEDs. Connecting the LM317K directly to the aluminum plate makes the plate electrically hot at 1.2V, necessitating precautions to avoid contact with live conductors. To ensure electrical isolation from the mounting plate, the LM317 can be mounted with an insulator and plastic shoulder washers. The LEDs are mounted on individual star-shaped aluminum substrates and attached to the aluminum plate with two 7/16" 4-40 screws and nuts per LED. A drop of silicone heat sink grease should be applied to each LED star's center for effective heat conduction. It is essential to use insulating plastic washers on the top side of the LED stars to prevent electrical contact with the screw heads. The LED stars are soldered together using short pieces of #20 tinned wire after being mounted. Sufficient heat is required for soldering, with a 200/240W soldering gun recommended. Care must be taken to avoid melting the LED lenses, which cost around $10 each. The positive and negative leads of the LED series string are connected back to the current regulator circuitry using #20 wire with Teflon insulation. The initial mechanical arrangement must pass the "rule of thumb" test, which states that if a semiconductor is too hot to hold your thumb on, its lifespan will be compromised. Two large aluminum heat sinks are bolted to the back of the aluminum plate, providing adequate cooling for the lamp. The LED array generates more heat than the LM317K. This circuit should be connected to a 24VDC power supply or an alternative source, such as a solar-charged lead-acid battery, ensuring correct polarity is observed. It is important to look away from the LEDs when applying power, as they are bright enough to cause vision damage. A switch-mode power supply rated at 24VDC and 1 Amp or higher is considered the most energy-efficient method for powering this device from line power.This project involves constructing an energy efficient broad spectrum LED lamp system. The lamp is useful for indoor reflective room lighting. It has a broad color spectrum that more closely approximates the light of the sun when compared to fluorescent bulbs and white-only LEDs. The light level is regulated and the light that is produced does not flicker. The six differently colored LED stars, made by LedEngin, Inc. , are rated at 5 watts (nominal). The LED array and associated current regulator consume 1 amp at 24VDC (24 Watts). NEVER stare directly at this lamp when it is running at full operating power, it is DANGEROUSLY BRIGHT. With the LEDs shown, the combined color of the lamp has a pinkish white hue. The 5 Watt ratings of the LEDs are not precise, the white, blue and green LEDs consume about 4W and the lower voltage red, orange and deep red LEDs consume about 3W.

The current regulator keeps the LED brightness constant and insures that the LED series string never draws more than 1 amp of current. The project has also been coined "Bold as LED" in reference to the Jimi Hendrix song "Bold as Love" which has the lyric: "My yellow in this case is not so mellow" The lamp is wired as a current loop which includes the power supply, the LED series string and the 1 amp current regulator circuit.

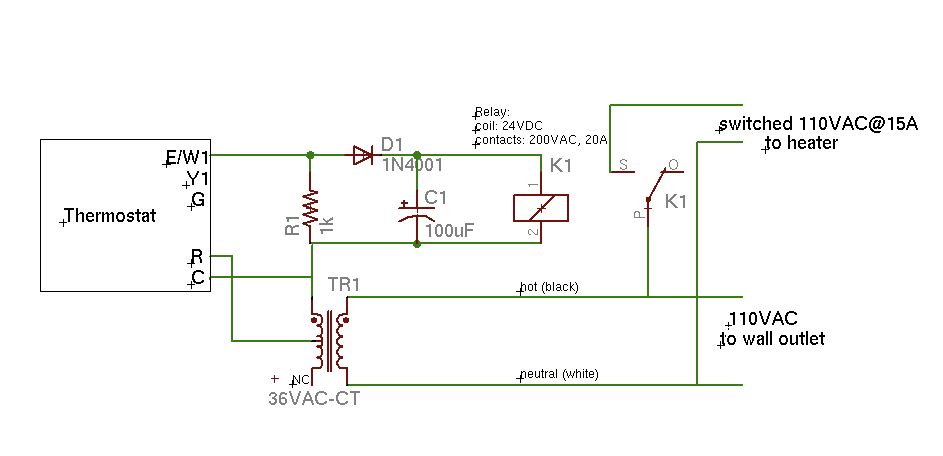

The LM317K and 1. 2 ohm 5 Watt resistor act as a current regulator that limits the loop current to 1 Amp. During regulation, there will always be 1. 2V across the 1. 2 ohm resistor. The current regulator insures that the LEDs always run at their maximum brightness, but not so bright that they burn out. A 100uF electrolytic capacitor bypasses the DC power input to the device and a 100nF monoblock capacitor bypasses the LM317K input.

The LEDs and current regulator circuit were mounted on a 3" x 8" chunk of 1/8" aluminum stock. The LM317K regulator and LED heat sinks were bolted to the chassis directly, heat sink grease was used on the regulator, the heat sinks and the six LEDs. Connecting the LM317K directly to the aluminum plate makes the plate electrically hot at 1. 2V, the plate should not be allowed to come into contact with any live conductors. By using a few more parts, the LM317 can be mounted with an insulator and plastic shoulder washers for electrical isolation from the mounting plate.

The LEDs come mounted on their own small star-shaped aluminum substrates, these were attached to the aluminum plate using two 7/16" 4-40 screws and nuts per LED. A drop of silicone heat sink grease should be applied to the center of each LED star when it is mounted to the plate for heat conduction.

It is important to use insulating plastic washers on the top side of the LED stars to prevent electrical contact with head of the screw. The LED stars were soldered together using short pieces of #20 tinned wire after being mounted on the plate.

It is necessary to use a fair amount of heat to solder the contacts, a 200/240W soldering gun did the job. Be very careful not to melt the lenses on the LEDs, the LEDs cost around $10 each. The positive and negative leads of the LED series string were connected back to the current reglator circuitry using #20 wire covered with teflon insulation.

The initial mechanical arrangement did not pass the "rule of thumb" test, which says that if a semiconductor is too hot to hold your thumb on, it will not live a long life. Two large aluminum heat sinks were bolted to the back of the aluminum plate and seem to be sufficient to keep the lamp operating at a reasonable temperature.

The LED array produces more heat than the LM317K. Connect this circuit to a 24VDC power supply or other power source such as a solar-charged lead acid battery. Be sure to observe the correct polarity. Look away from the LEDs and apply power. Again, do not stare directly at the LEDs, they are bright enough to harm your vision. A switch-mode power supply rated at 24VDC and 1 Amp or more is probably the most energy-efficient way to power this device from line power.

🔗 External reference

The current regulator keeps the LED brightness constant and insures that the LED series string never draws more than 1 amp of current. The project has also been coined "Bold as LED" in reference to the Jimi Hendrix song "Bold as Love" which has the lyric: "My yellow in this case is not so mellow" The lamp is wired as a current loop which includes the power supply, the LED series string and the 1 amp current regulator circuit.

The LM317K and 1. 2 ohm 5 Watt resistor act as a current regulator that limits the loop current to 1 Amp. During regulation, there will always be 1. 2V across the 1. 2 ohm resistor. The current regulator insures that the LEDs always run at their maximum brightness, but not so bright that they burn out. A 100uF electrolytic capacitor bypasses the DC power input to the device and a 100nF monoblock capacitor bypasses the LM317K input.

The LEDs and current regulator circuit were mounted on a 3" x 8" chunk of 1/8" aluminum stock. The LM317K regulator and LED heat sinks were bolted to the chassis directly, heat sink grease was used on the regulator, the heat sinks and the six LEDs. Connecting the LM317K directly to the aluminum plate makes the plate electrically hot at 1. 2V, the plate should not be allowed to come into contact with any live conductors. By using a few more parts, the LM317 can be mounted with an insulator and plastic shoulder washers for electrical isolation from the mounting plate.

The LEDs come mounted on their own small star-shaped aluminum substrates, these were attached to the aluminum plate using two 7/16" 4-40 screws and nuts per LED. A drop of silicone heat sink grease should be applied to the center of each LED star when it is mounted to the plate for heat conduction.

It is important to use insulating plastic washers on the top side of the LED stars to prevent electrical contact with head of the screw. The LED stars were soldered together using short pieces of #20 tinned wire after being mounted on the plate.

It is necessary to use a fair amount of heat to solder the contacts, a 200/240W soldering gun did the job. Be very careful not to melt the lenses on the LEDs, the LEDs cost around $10 each. The positive and negative leads of the LED series string were connected back to the current reglator circuitry using #20 wire covered with teflon insulation.

The initial mechanical arrangement did not pass the "rule of thumb" test, which says that if a semiconductor is too hot to hold your thumb on, it will not live a long life. Two large aluminum heat sinks were bolted to the back of the aluminum plate and seem to be sufficient to keep the lamp operating at a reasonable temperature.

The LED array produces more heat than the LM317K. Connect this circuit to a 24VDC power supply or other power source such as a solar-charged lead acid battery. Be sure to observe the correct polarity. Look away from the LEDs and apply power. Again, do not stare directly at the LEDs, they are bright enough to harm your vision. A switch-mode power supply rated at 24VDC and 1 Amp or more is probably the most energy-efficient way to power this device from line power.

🔗 External reference