resistance Replicate thermistor behavior for second sensor

An R/C electric motor is equipped with a 10K thermistor sensor, which connects to a speed control unit that includes basic thermal protection. A secondary sensor board is intended to be developed to display the temperature on a segment display while still transmitting the temperature data to the speed control for thermal protection. Currently, the thermistor is only connected to ground on one end, lacking a reference potential. To address this, a voltage divider will be implemented for reading the thermistor. However, directly passing the end of the thermistor back to the speed control is not feasible, as the speed control may utilize its own voltage divider. A solution is sought to replicate the thermistor's resistance for two different reading circuits that expect variable resistance.

To achieve the desired functionality of the secondary sensor board while maintaining the thermal protection provided by the speed control, a careful design approach must be employed. The thermistor, as a temperature-sensitive resistor, varies its resistance based on temperature changes. In this case, a 10K NTC (Negative Temperature Coefficient) thermistor is used, where resistance decreases as temperature increases.

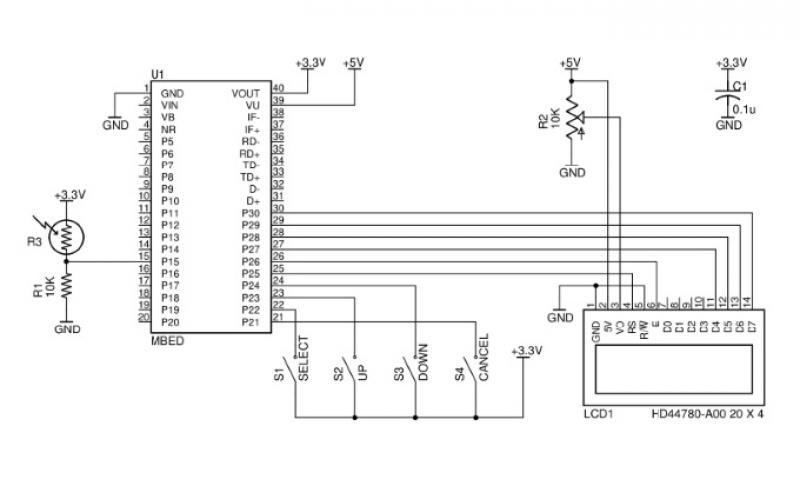

The first step involves creating a voltage divider circuit to read the thermistor's resistance. This can be accomplished by connecting the thermistor in series with a fixed resistor (R1) to form a divider. The voltage across the thermistor can be measured and converted to a temperature reading using an analog-to-digital converter (ADC). The value of R1 should be chosen to match the thermistor's nominal resistance at the expected operating temperature, typically around 10K at 25°C.

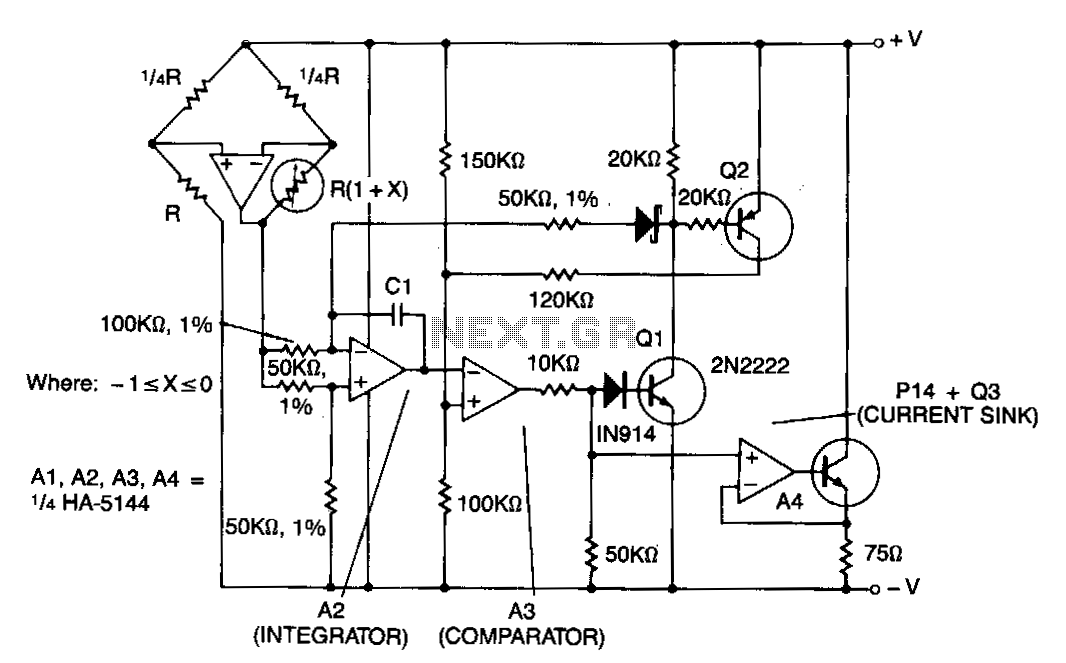

To facilitate the dual functionality of reading the thermistor for both the display and the speed control, an operational amplifier (op-amp) can be utilized. The op-amp can buffer the voltage reading from the voltage divider, allowing it to drive both the segment display and the speed control input without affecting the measurement accuracy. This configuration ensures that the speed control receives a stable and accurate representation of the thermistor's resistance.

Additionally, to ensure that the speed control's thermal protection remains effective, it is crucial to isolate the two circuits. This can be achieved by using an isolation amplifier or a second op-amp configured as a non-inverting buffer. This approach allows the thermistor's output to be replicated accurately for both the speed control and the display without interference from one circuit to the other.

In summary, the design should include a voltage divider to read the thermistor, an op-amp to buffer the signal, and isolation techniques to ensure that both the segment display and the speed control receive the necessary temperature data without compromising functionality. This comprehensive approach will enable effective temperature monitoring while preserving the thermal protection capabilities of the speed control unit.An R/C electric motor that has a 10K thermistor sensor built into it, which is connected to a speed control that has basic thermal protection. I would like to build a secondary sensor board that displays the temperature on a segment display, but I still want to pass it through to the speed control so that it still has thermal prot

ection. The issue I`m having is that the thermistor is only connected to ground on one end, no other reference potential, so I plan to read it with a voltage divider. This means I can`t just pass the end of the thermistor back through to the speed control, which may have its own voltage divider.

Is there a way I can replicate the resistance of the thermistor to two different read circuits expecting a variable resistance 🔗 External reference

To achieve the desired functionality of the secondary sensor board while maintaining the thermal protection provided by the speed control, a careful design approach must be employed. The thermistor, as a temperature-sensitive resistor, varies its resistance based on temperature changes. In this case, a 10K NTC (Negative Temperature Coefficient) thermistor is used, where resistance decreases as temperature increases.

The first step involves creating a voltage divider circuit to read the thermistor's resistance. This can be accomplished by connecting the thermistor in series with a fixed resistor (R1) to form a divider. The voltage across the thermistor can be measured and converted to a temperature reading using an analog-to-digital converter (ADC). The value of R1 should be chosen to match the thermistor's nominal resistance at the expected operating temperature, typically around 10K at 25°C.

To facilitate the dual functionality of reading the thermistor for both the display and the speed control, an operational amplifier (op-amp) can be utilized. The op-amp can buffer the voltage reading from the voltage divider, allowing it to drive both the segment display and the speed control input without affecting the measurement accuracy. This configuration ensures that the speed control receives a stable and accurate representation of the thermistor's resistance.

Additionally, to ensure that the speed control's thermal protection remains effective, it is crucial to isolate the two circuits. This can be achieved by using an isolation amplifier or a second op-amp configured as a non-inverting buffer. This approach allows the thermistor's output to be replicated accurately for both the speed control and the display without interference from one circuit to the other.

In summary, the design should include a voltage divider to read the thermistor, an op-amp to buffer the signal, and isolation techniques to ensure that both the segment display and the speed control receive the necessary temperature data without compromising functionality. This comprehensive approach will enable effective temperature monitoring while preserving the thermal protection capabilities of the speed control unit.An R/C electric motor that has a 10K thermistor sensor built into it, which is connected to a speed control that has basic thermal protection. I would like to build a secondary sensor board that displays the temperature on a segment display, but I still want to pass it through to the speed control so that it still has thermal prot

ection. The issue I`m having is that the thermistor is only connected to ground on one end, no other reference potential, so I plan to read it with a voltage divider. This means I can`t just pass the end of the thermistor back through to the speed control, which may have its own voltage divider.

Is there a way I can replicate the resistance of the thermistor to two different read circuits expecting a variable resistance 🔗 External reference