robot tutorial dc motor control system

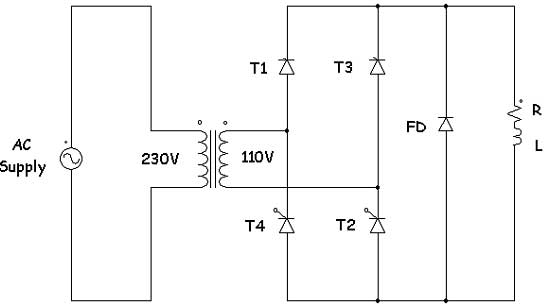

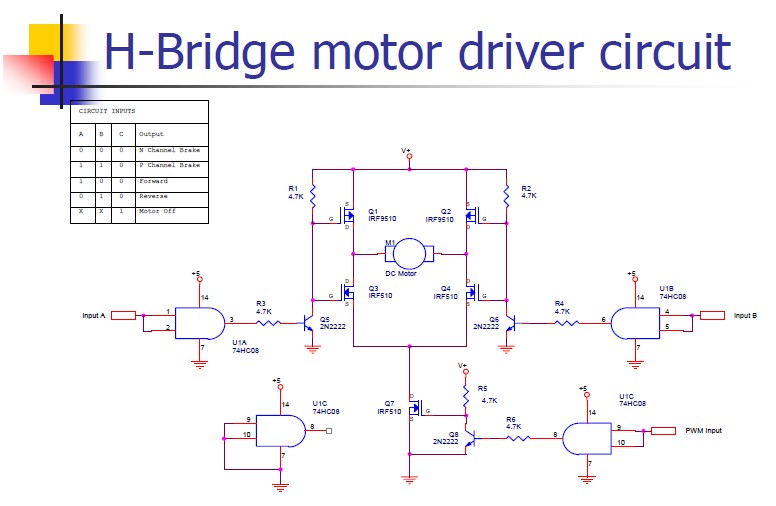

An H-bridge motor driver circuit is designed to control a DC motor. By using a low signal, such as a 5-volt signal, the circuit enables the program to manage the motor, which operates on a higher power supply.

The H-bridge motor driver circuit is a fundamental component in motor control applications, particularly for DC motors. It allows for bidirectional control of the motor by enabling current to flow in either direction through the motor windings. The circuit typically consists of four switches, which can be implemented using transistors or MOSFETs. These switches are arranged in an H configuration, hence the name "H-bridge."

When a low control signal is applied to the H-bridge, it activates specific switches to allow current flow in one direction, causing the motor to spin in one direction. Conversely, reversing the control signals activates the opposite switches, allowing current to flow in the opposite direction and reversing the motor's rotation. This functionality is crucial for applications requiring precise control over motor direction and speed.

The use of a low voltage control signal, such as 5 volts, is advantageous as it allows microcontrollers or other low-power devices to interface with high-power motor systems without the need for complex and bulky control circuitry. The H-bridge can also incorporate features such as PWM (Pulse Width Modulation) for speed control, enabling fine-tuning of the motor's performance.

In practical implementations, additional components such as diodes may be included to protect the circuit from back EMF generated by the motor during operation. Heat sinks or thermal management strategies may also be necessary to dissipate heat generated by the power devices in the H-bridge, ensuring reliable operation under load conditions.

Overall, the H-bridge motor driver circuit is essential for efficient and effective control of DC motors in various applications, ranging from robotics to industrial automation.H-bridge motor driver circuit to drive the DC motor, so that with low signal (say 5 volt signal), the program will able to control the motor which use high power supply. 🔗 External reference

The H-bridge motor driver circuit is a fundamental component in motor control applications, particularly for DC motors. It allows for bidirectional control of the motor by enabling current to flow in either direction through the motor windings. The circuit typically consists of four switches, which can be implemented using transistors or MOSFETs. These switches are arranged in an H configuration, hence the name "H-bridge."

When a low control signal is applied to the H-bridge, it activates specific switches to allow current flow in one direction, causing the motor to spin in one direction. Conversely, reversing the control signals activates the opposite switches, allowing current to flow in the opposite direction and reversing the motor's rotation. This functionality is crucial for applications requiring precise control over motor direction and speed.

The use of a low voltage control signal, such as 5 volts, is advantageous as it allows microcontrollers or other low-power devices to interface with high-power motor systems without the need for complex and bulky control circuitry. The H-bridge can also incorporate features such as PWM (Pulse Width Modulation) for speed control, enabling fine-tuning of the motor's performance.

In practical implementations, additional components such as diodes may be included to protect the circuit from back EMF generated by the motor during operation. Heat sinks or thermal management strategies may also be necessary to dissipate heat generated by the power devices in the H-bridge, ensuring reliable operation under load conditions.

Overall, the H-bridge motor driver circuit is essential for efficient and effective control of DC motors in various applications, ranging from robotics to industrial automation.H-bridge motor driver circuit to drive the DC motor, so that with low signal (say 5 volt signal), the program will able to control the motor which use high power supply. 🔗 External reference