Simplest Piezo Driver Circuit Explained

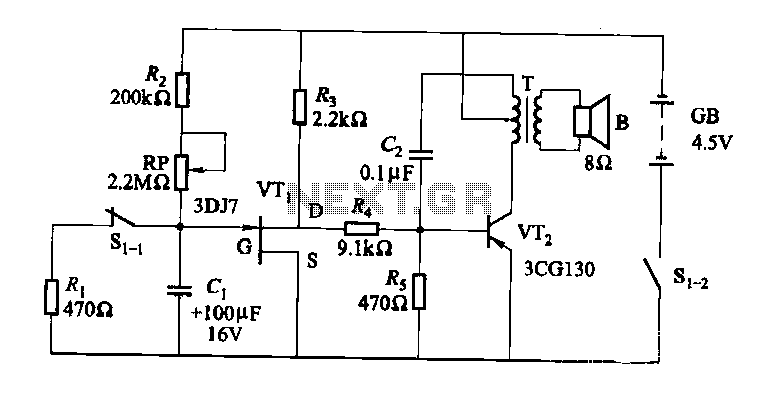

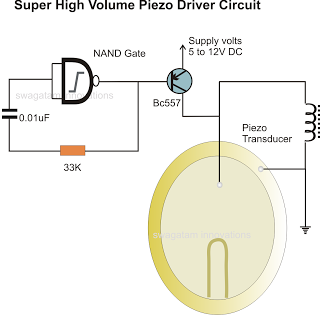

In the previous post, a piezo transducer element was discussed, along with its application in electronic circuits. This article will explore how a piezo transducer can be driven or operated using a simple circuit. The amplification method differs from conventional amplifying circuits typically used in systems with speakers; instead, it is implemented through an inexpensive inductor. The low power frequency from a relevant circuit or an integrated circuit (IC) is first amplified using a transistor. Subsequently, the transistor output is enhanced using an inductor. The use of an inductor is a crucial stage in driving a piezoelectric transducer.

The circuit for driving a piezoelectric transducer typically involves several key components: a low-power signal source, a transistor, an inductor, and the piezo transducer itself. The signal source can be a microcontroller or any other low-frequency oscillator capable of generating a suitable signal. The transistor acts as a switch or an amplifier, allowing the low power signal to control a larger current flowing through the inductor.

The inductor plays a pivotal role in this circuit by storing energy when current flows through it. When the transistor is activated, the current builds up in the inductor, which then releases this energy to the piezo transducer, generating a mechanical vibration. This process effectively translates the electrical signal into a mechanical output, which is the fundamental operation of a piezoelectric device.

The choice of transistor is important, as it must be capable of handling the required current and voltage levels without overheating. Common transistor types used in this application include bipolar junction transistors (BJTs) or field-effect transistors (FETs), depending on the specific circuit requirements.

Additionally, the inductor value should be selected based on the frequency of operation and the desired resonance characteristics of the piezo transducer. A higher inductance will allow for more energy storage, enhancing the output to the transducer but may also affect the response time of the circuit.

In summary, the circuit for driving a piezoelectric transducer is a straightforward yet effective design that utilizes a transistor and an inductor to amplify a low-power signal, ultimately enabling the transducer to convert electrical energy into mechanical vibrations efficiently. Proper selection of components and circuit parameters is essential for optimal performance in various applications, including sound generation, sensing, and actuation.In the previous post we discussed a piezo transducer element and learned how to use it with electronic circuits. In this article we will see how a piezo tranducer can be driven or operated using a simple circuit. However the amplification procedure is not by using conventional amplifying circuits as used in systems incorporating speakers, but rath

er it is simply implemented through an inexpensive inductor. The low power frequency which may be available from a relevant circuit or an IC is first amplified using a transistor, and further more the transistor output is pumped up using an inductor. The use of a inductor becomes the most crucial stage for driving a piezo electric transducer. 🔗 External reference

The circuit for driving a piezoelectric transducer typically involves several key components: a low-power signal source, a transistor, an inductor, and the piezo transducer itself. The signal source can be a microcontroller or any other low-frequency oscillator capable of generating a suitable signal. The transistor acts as a switch or an amplifier, allowing the low power signal to control a larger current flowing through the inductor.

The inductor plays a pivotal role in this circuit by storing energy when current flows through it. When the transistor is activated, the current builds up in the inductor, which then releases this energy to the piezo transducer, generating a mechanical vibration. This process effectively translates the electrical signal into a mechanical output, which is the fundamental operation of a piezoelectric device.

The choice of transistor is important, as it must be capable of handling the required current and voltage levels without overheating. Common transistor types used in this application include bipolar junction transistors (BJTs) or field-effect transistors (FETs), depending on the specific circuit requirements.

Additionally, the inductor value should be selected based on the frequency of operation and the desired resonance characteristics of the piezo transducer. A higher inductance will allow for more energy storage, enhancing the output to the transducer but may also affect the response time of the circuit.

In summary, the circuit for driving a piezoelectric transducer is a straightforward yet effective design that utilizes a transistor and an inductor to amplify a low-power signal, ultimately enabling the transducer to convert electrical energy into mechanical vibrations efficiently. Proper selection of components and circuit parameters is essential for optimal performance in various applications, including sound generation, sensing, and actuation.In the previous post we discussed a piezo transducer element and learned how to use it with electronic circuits. In this article we will see how a piezo tranducer can be driven or operated using a simple circuit. However the amplification procedure is not by using conventional amplifying circuits as used in systems incorporating speakers, but rath

er it is simply implemented through an inexpensive inductor. The low power frequency which may be available from a relevant circuit or an IC is first amplified using a transistor, and further more the transistor output is pumped up using an inductor. The use of a inductor becomes the most crucial stage for driving a piezo electric transducer. 🔗 External reference