Small DC Motor Speed Controller

Electric motors have been widely used for motion control, and various types of motor controllers have been designed to provide variable speed drives for these motors.

Electric motors are integral to numerous applications requiring precise motion control, ranging from industrial automation to consumer electronics. The ability to modulate the speed and torque of electric motors is essential for optimizing performance and energy efficiency. Motor controllers serve as the interface between the power supply and the motor, allowing for the adjustment of operational parameters based on the specific requirements of the application.

There are several types of motor controllers, including but not limited to:

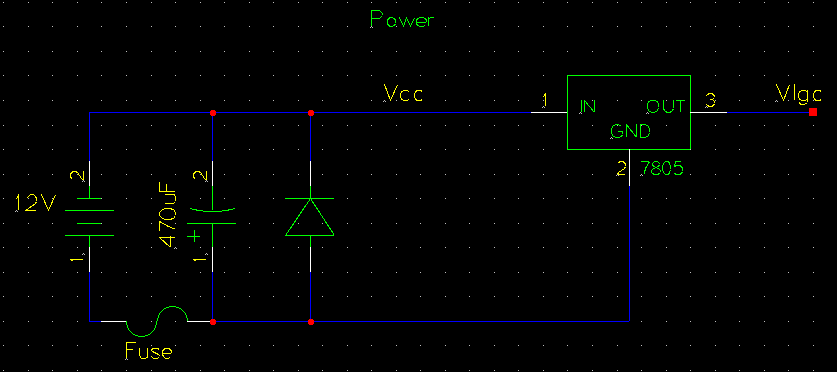

1. **DC Motor Controllers**: These controllers utilize pulse width modulation (PWM) techniques to adjust the voltage applied to the motor, thus controlling its speed. They are commonly used in battery-operated devices and applications where variable speed is required.

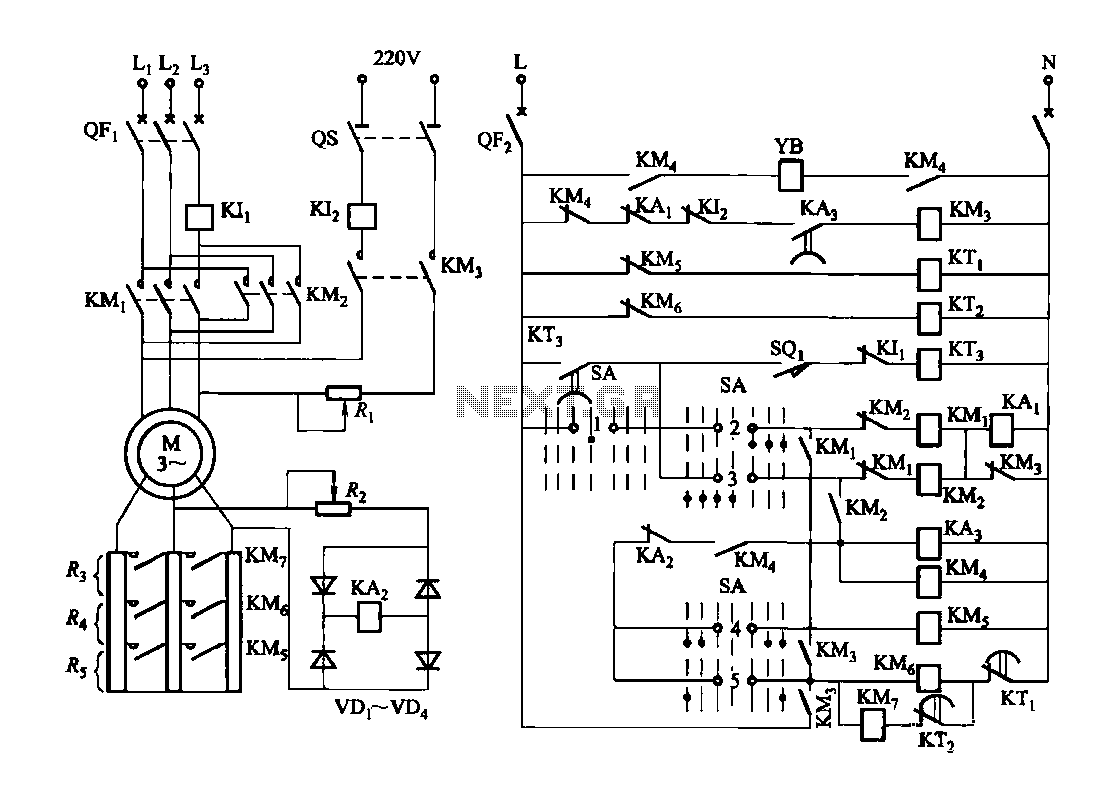

2. **AC Motor Controllers**: These controllers manage the speed of AC motors by varying the frequency and voltage of the power supplied to the motor. Variable Frequency Drives (VFDs) are a popular example, allowing for smooth acceleration and deceleration, which enhances the longevity of the motor and reduces mechanical stress.

3. **Stepper Motor Controllers**: Designed for stepper motors, these controllers manage the precise positioning of the motor by sending a series of pulses that dictate the motor's movements. They are widely used in applications requiring high precision, such as 3D printers and CNC machines.

4. **Servo Motor Controllers**: These controllers are used in conjunction with feedback systems to maintain the desired position, speed, or torque of the motor. They are essential in robotics and automation, where accuracy and responsiveness are critical.

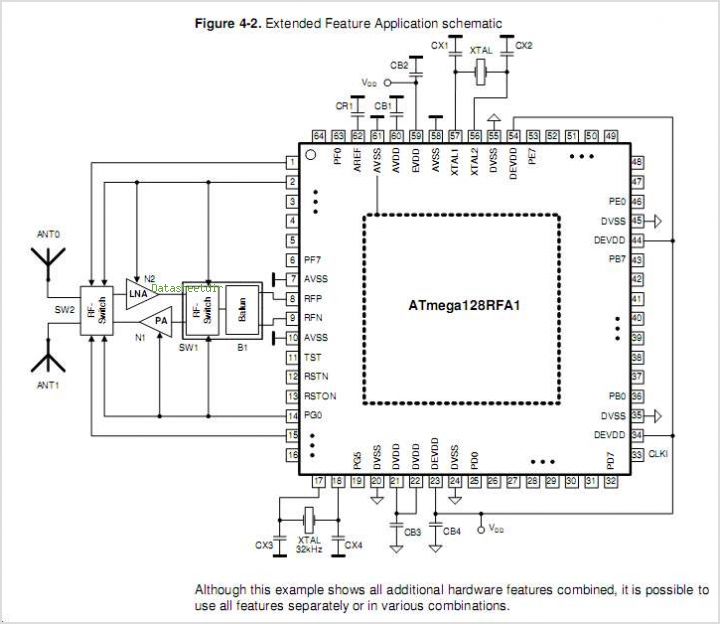

The design of motor controllers can vary significantly based on the application requirements, including factors such as load characteristics, operating environment, and desired control algorithms. Advanced motor controllers may incorporate microcontrollers or digital signal processors (DSPs) for enhanced control capabilities, allowing for complex algorithms that can adapt to changing load conditions.

In conclusion, the development of motor controllers has evolved to meet the demands of modern applications, providing efficient and precise control of electric motors across various sectors. The choice of motor controller is crucial in achieving optimal performance and reliability in motion control systems.Electric motor has been widely used as motion control, and many? type of motor controllers? have been designed to provide variable speed drives for the motor 🔗 External reference

Electric motors are integral to numerous applications requiring precise motion control, ranging from industrial automation to consumer electronics. The ability to modulate the speed and torque of electric motors is essential for optimizing performance and energy efficiency. Motor controllers serve as the interface between the power supply and the motor, allowing for the adjustment of operational parameters based on the specific requirements of the application.

There are several types of motor controllers, including but not limited to:

1. **DC Motor Controllers**: These controllers utilize pulse width modulation (PWM) techniques to adjust the voltage applied to the motor, thus controlling its speed. They are commonly used in battery-operated devices and applications where variable speed is required.

2. **AC Motor Controllers**: These controllers manage the speed of AC motors by varying the frequency and voltage of the power supplied to the motor. Variable Frequency Drives (VFDs) are a popular example, allowing for smooth acceleration and deceleration, which enhances the longevity of the motor and reduces mechanical stress.

3. **Stepper Motor Controllers**: Designed for stepper motors, these controllers manage the precise positioning of the motor by sending a series of pulses that dictate the motor's movements. They are widely used in applications requiring high precision, such as 3D printers and CNC machines.

4. **Servo Motor Controllers**: These controllers are used in conjunction with feedback systems to maintain the desired position, speed, or torque of the motor. They are essential in robotics and automation, where accuracy and responsiveness are critical.

The design of motor controllers can vary significantly based on the application requirements, including factors such as load characteristics, operating environment, and desired control algorithms. Advanced motor controllers may incorporate microcontrollers or digital signal processors (DSPs) for enhanced control capabilities, allowing for complex algorithms that can adapt to changing load conditions.

In conclusion, the development of motor controllers has evolved to meet the demands of modern applications, providing efficient and precise control of electric motors across various sectors. The choice of motor controller is crucial in achieving optimal performance and reliability in motion control systems.Electric motor has been widely used as motion control, and many? type of motor controllers? have been designed to provide variable speed drives for the motor 🔗 External reference